Feed adding device for chicken breeding

A technology for adding feed and installing holes, which is applied in the field of feed adding devices for chicken breeding, which can solve the problems of high labor intensity, low work efficiency, and endangering the health of chicken farmers, and achieve the effects of reducing feeding time and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

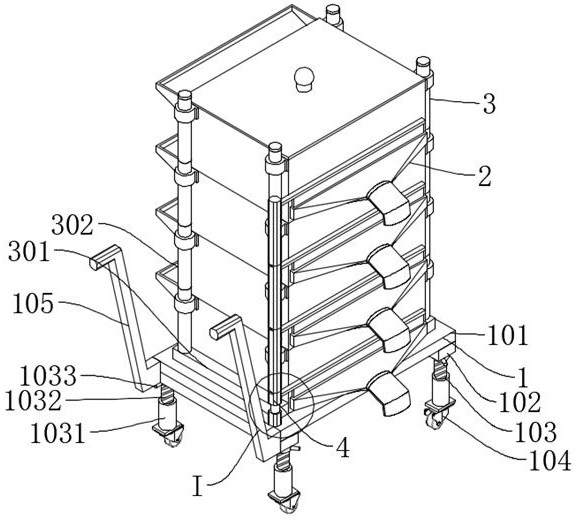

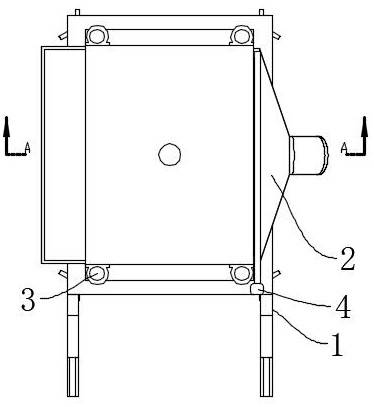

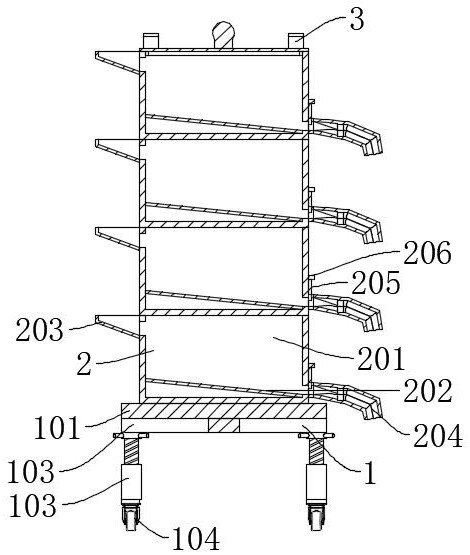

[0036] Such as Figure 1-7 As shown, a feed adding device for chicken breeding includes a height-adjustable mobile trolley 1, and also includes several feed adding mechanisms 2, fixing mechanisms 3 and driving mechanisms 4 that can be combined vertically, and the feed adding mechanism 2 includes The storage box 201, deflector 202, hopper 203, discharge pipe 204, inserting plate 205, connecting rod 206, sliding sleeve 207, the storage box 201 is connected to the top of the mobile trolley 1 by bolts, and the inside bottom of the storage box 201 is welded with an inclined The deflector 202 is set, the storage box 201 side is provided with a feeding port, the outside of the feeding port is connected with a feeding hopper 203 by bolts, and the other side of the storage box 201 is provided with a feeding port, and the outside of the feeding port is connected with a The discharge pipe 204 arranged obliquely downward, the top of the discharge pipe 204 close to the storage box 201 is p...

Embodiment 2

[0038] Such as Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that: the top of the limit rod 302 is provided with a mounting hole 3022, the bottom of the limit rod 302 is welded with a protruding rod 3021 that can be inserted into the inside of the mounting hole 3022, and the bottom of the protruding rod 3021 is The ferromagnetic block 30201 is connected by screws, so that it can be inserted into the inside of the protruding rod 3021 through the installation hole 3022, and the functional ferromagnetic block 30201 is adsorbed on the inside of the installation hole 3022, realizing the combination of multiple limit rods 302.

[0039] In the above structure, when in use, first install an appropriate number of feed addition mechanisms 2 according to the actual number of layers of the chicken cage. When installing, first place the feed addition mechanism 2 on the lower feed addition mechanism 2 until an appropriate amount of feed is added. The mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com