Roller screen of roller type feeding machine

A feeder and roller screen technology, applied in grain processing, etc., can solve the problems of increasing the wear of the crusher and affecting the efficiency of the crusher, and achieve the effects of improving production capacity, reducing wear, and reducing sticky and wet plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

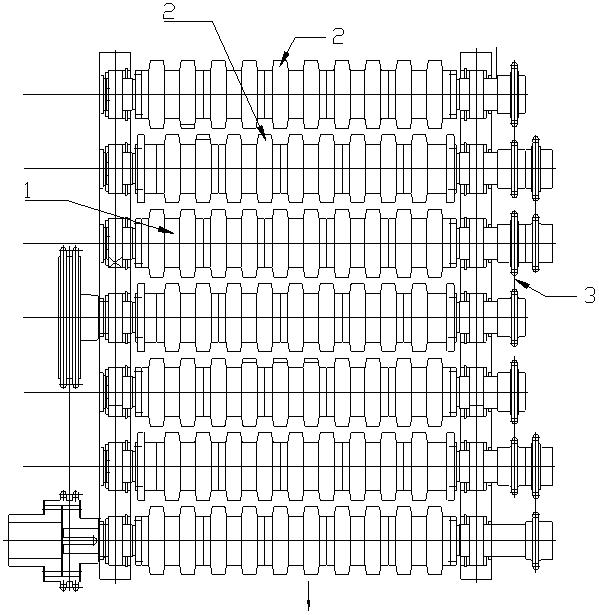

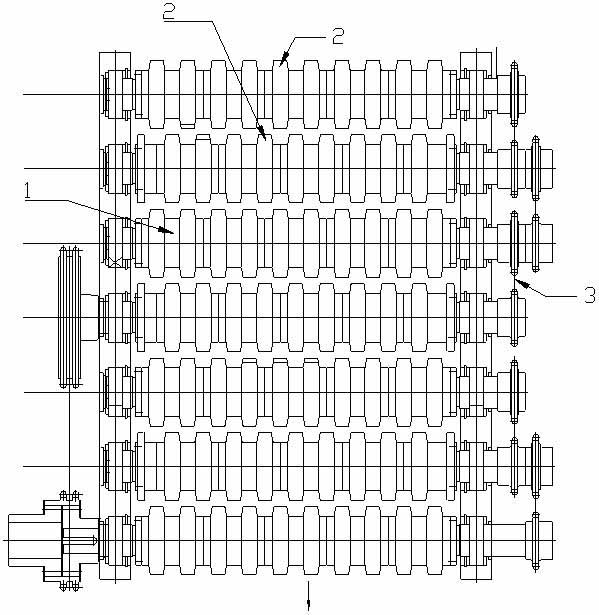

[0007] see figure 1 The height difference roller screen of the feeder shown includes seven roller shafts 1 that rotate in the same direction under the drive of the chain transmission mechanism 3, and a plurality of rollers 2 are arranged on the roller shaft along the axial direction, and two adjacent roller shafts The rollers 2 on the roller shaft are staggered in the axial direction.

[0008] This roller screen is a compound equipment with both feeding capacity and screening function. It is suitable for continuous feeding of heavy crushers. This is a front-type screening, which can screen out the fine materials that meet the requirements in the raw materials, which not only improves the production capacity of the crushing system, but also reduces the wear of the crusher. And because there are many mud components in the fine material, after they are screened out, the chance of the crusher being sticky and plugged can be reduced. The feeding particle size is 1250mm. The maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com