Labeling device capable of improving labeling quality

A quality and roller technology, applied in the field of automated processing, can solve the problems of increased workload, decreased product yield, and weak labeling, and achieves the effect of realizing the feeding function and improving the firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

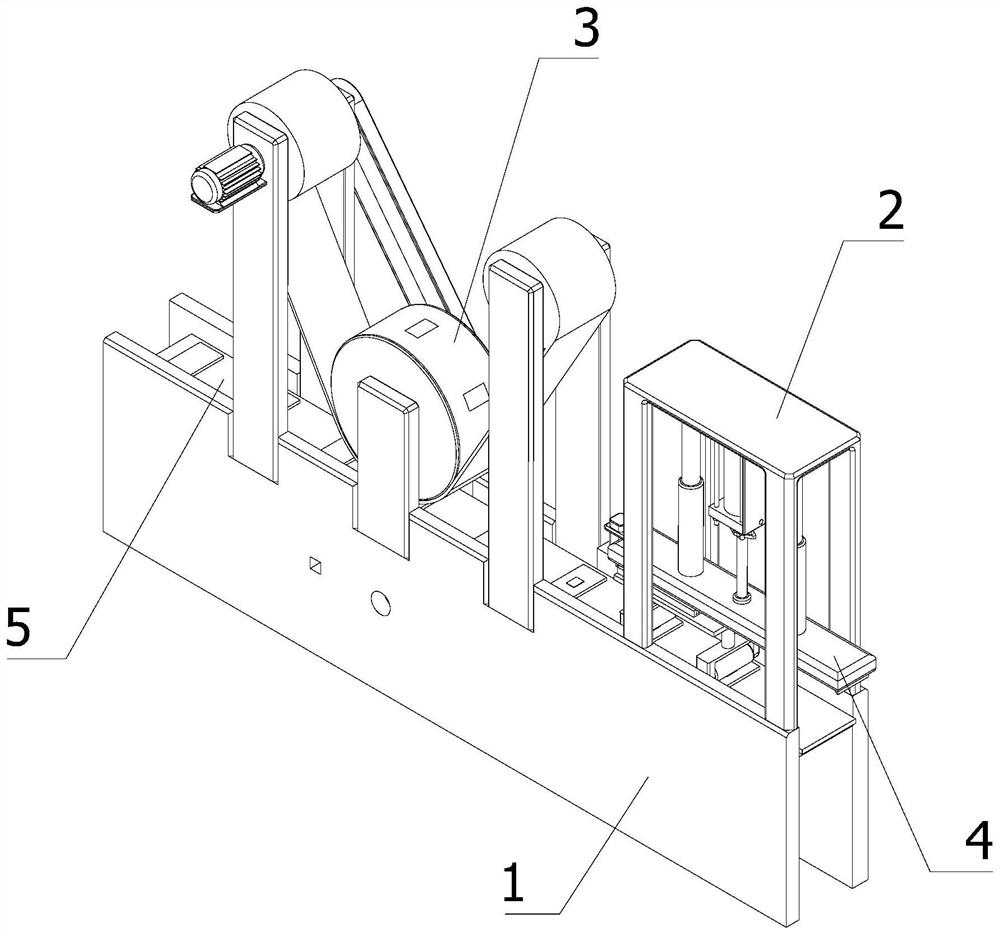

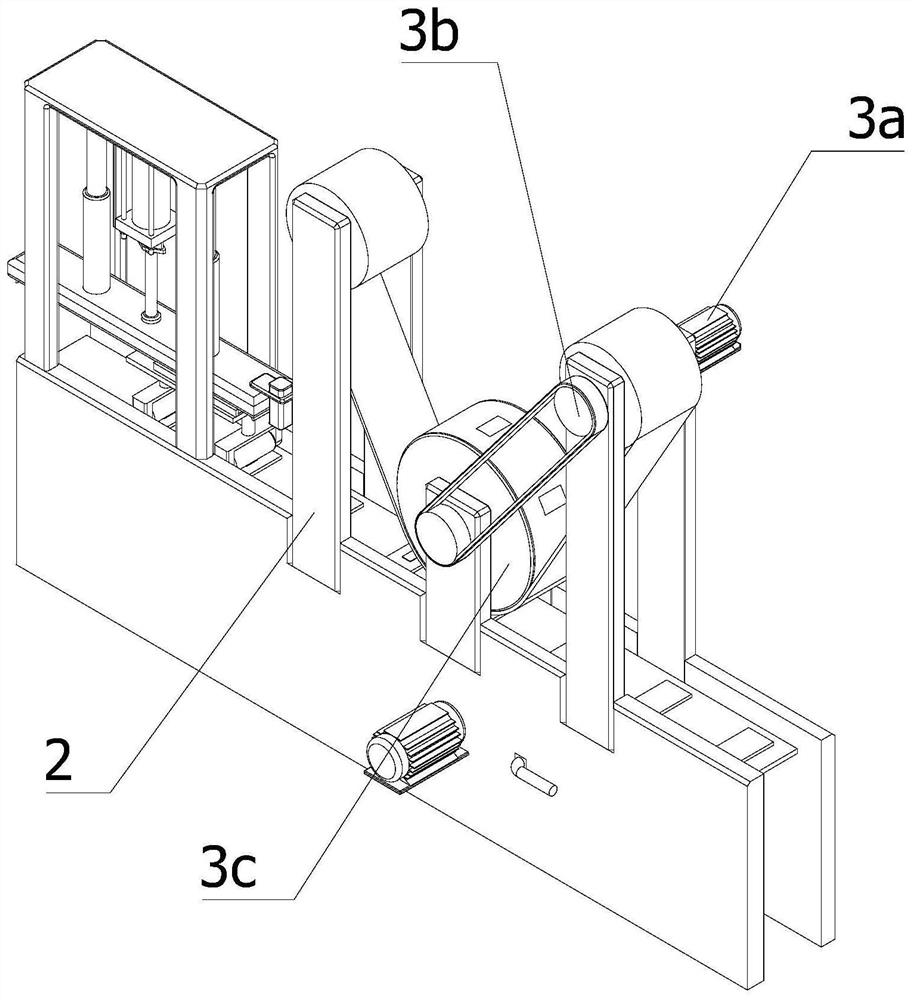

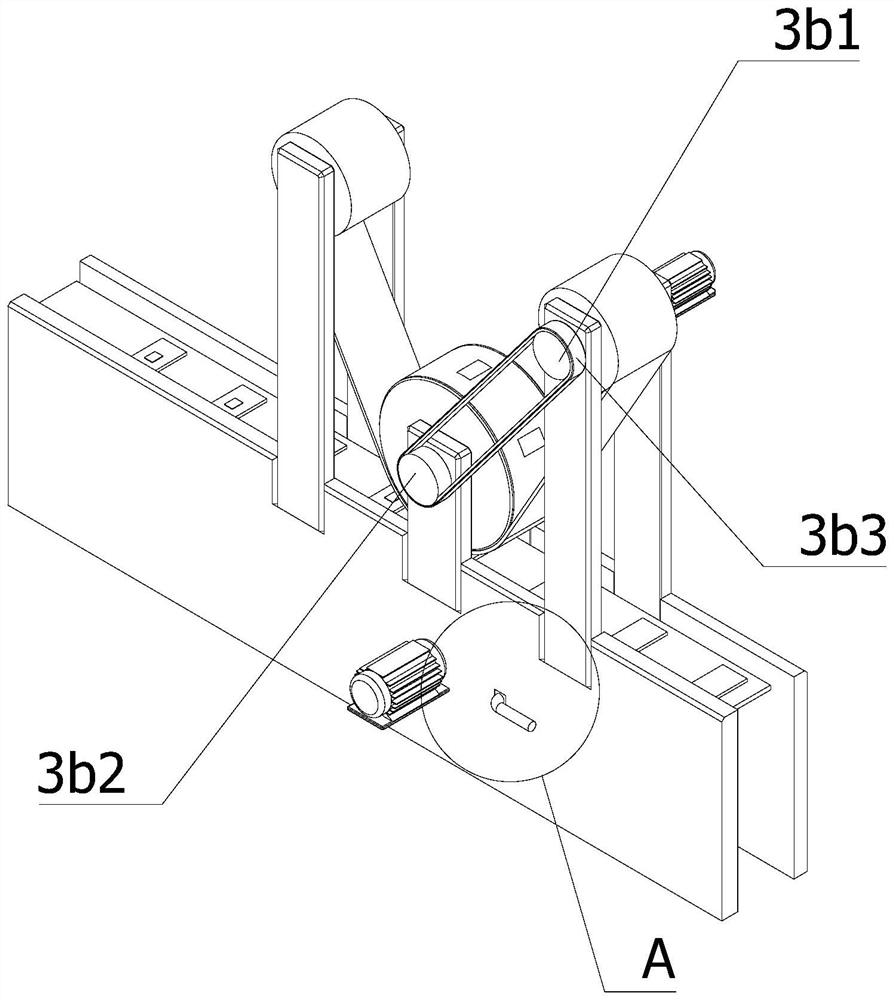

[0041] like Figure 1-15 As shown, this application provides:

[0042] A labeling device that can improve the quality of labeling, comprising a base 1, a support 2, a labeling mechanism 3 and a conveying mechanism 5; also includes a re-pressing mechanism 4, which is arranged on the bracket 2; the labeling mechanism 3 is arranged On the bracket 2, the labeling mechanism 3 includes a feeding assembly 3a, a transmission assembly 3b, a first roller 3c, a groove 3d, a slider 3e, a limit assembly 3f, a second roller 3g and a first magnet 3h; the feeding assembly 3a is arranged on the bracket 2; the first roller 3c is rotatably arranged on the bracket 2 below the feeding component 3a; the two ends of the transmission compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com