Material taking and conveying system of labeling machine

A conveying system and labeling machine technology, which is applied to labeling machines, conveyors, labeling, etc., can solve the problems of nurses' consumption, large equipment volume, insufficient slideway capacity, and disorderly placement, etc. Clamping and lifting efficiency, conducive to standardization, and the effect of avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the examples, but it should not be construed as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. Break away from the protection scope of the present invention.

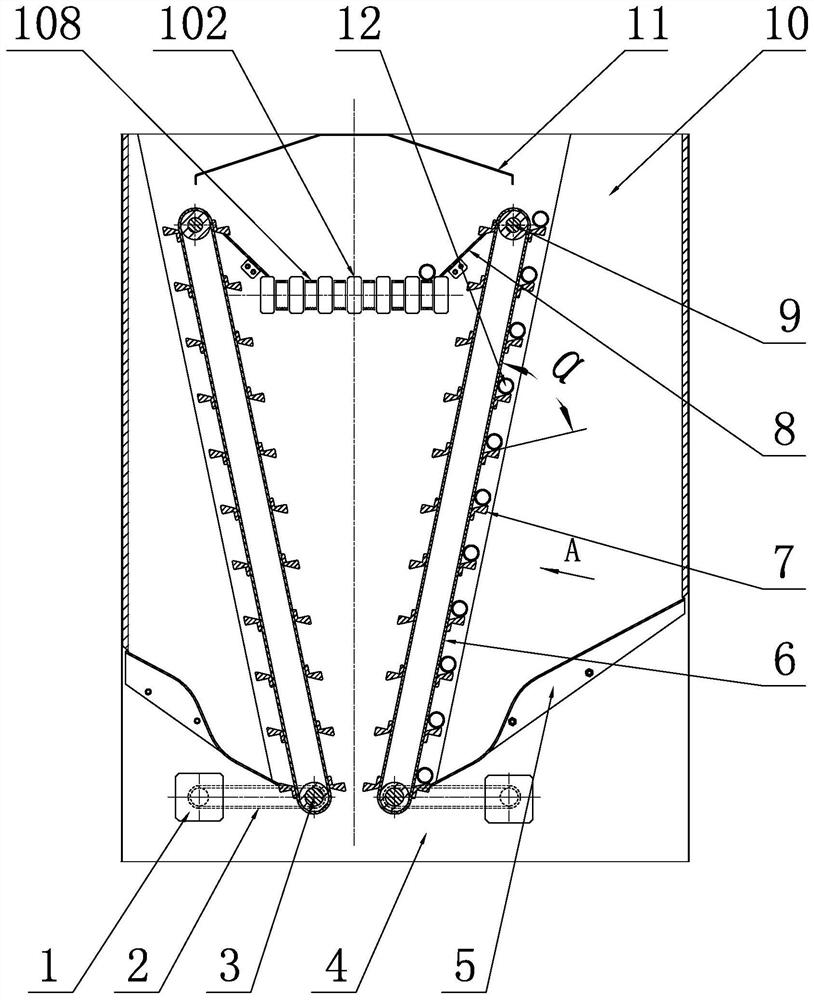

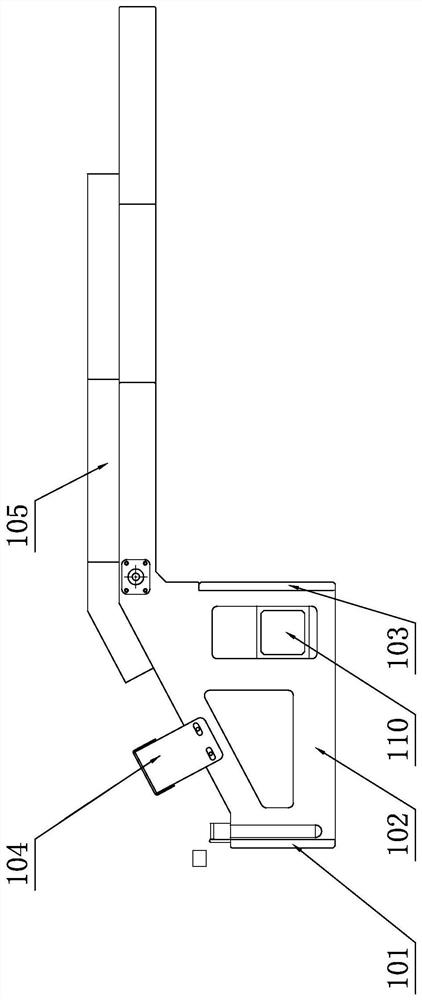

[0054] The overall structure of this embodiment is as shown in the figure, which includes a hopper with an open top and can accommodate blood collection test tubes 12; it also includes:

[0055] A. Test tube lifting device

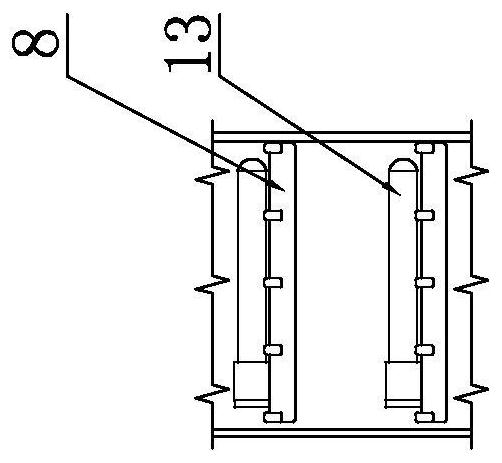

[0056] The hopper is provided with a first belt conveying mechanism driven by the first power source 1 and the transmission belt 2 and composed of the first driving wheel 3, the first driven wheel 9 and the first belt 6. The claw 7, the claw 7 and the belt of the first belt conveying mechanism can form a clamping effect on the blood collection test tube 12, and the material output at the top of the first belt conveying mechanism is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com