Fluoride/oxide co-coated positive electrode material and preparation method thereof

A cathode material, oxyfluoride technology, applied in the direction of positive electrode, electrode manufacturing, active material electrode, etc., can solve the problems of unpredictable coating effect, loose material structure, difficult coating layer, etc., to achieve good cycle Stability, damage reduction, good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

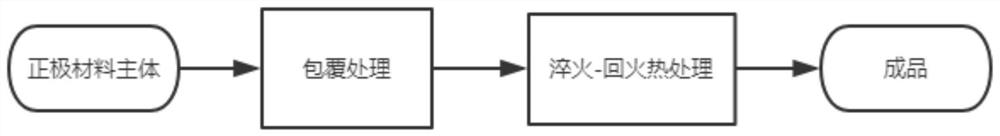

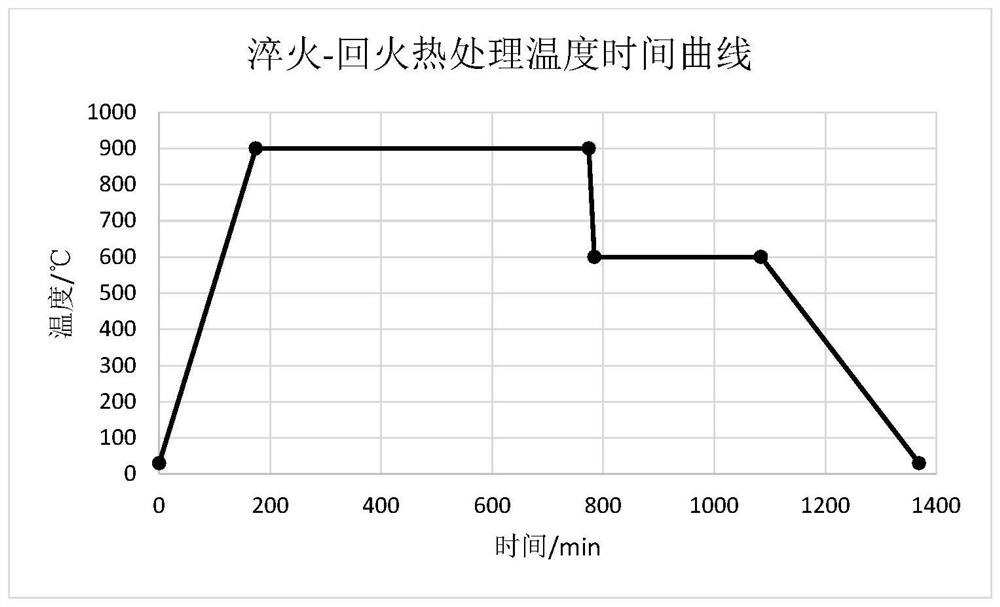

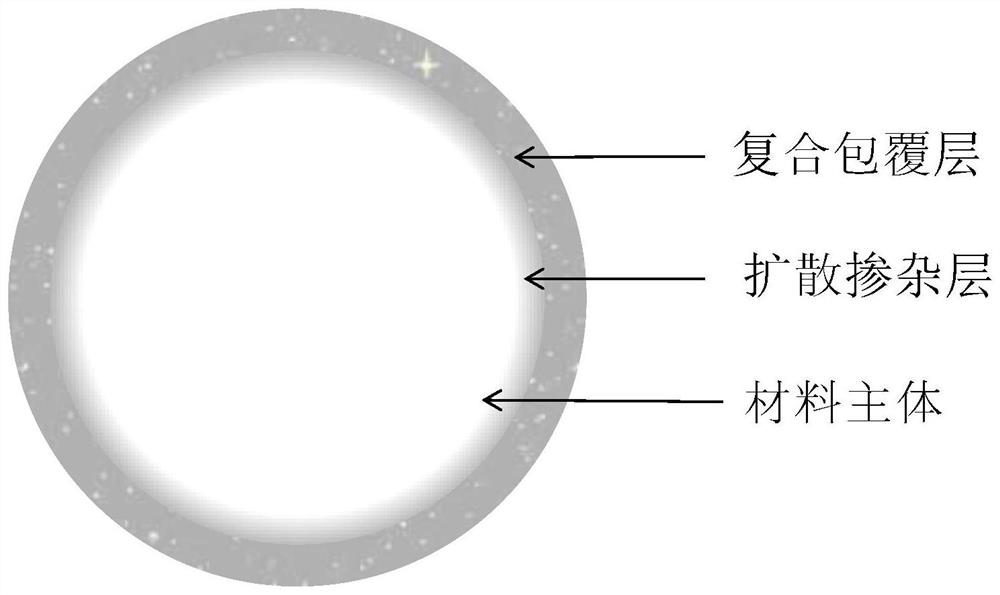

[0044] 500g of lithium cobaltate (LCO) and 5g of nano-Al 2 o 3 , MgO and TiF 4 , WF 6 Put it in a high-mixer and mix it at 4000rpm for 10 minutes. The ratio of metal elements added to the four materials is 3:3:2:2. After mixing evenly, put it in an atmosphere furnace and keep it warm at 900°C for 10 hours in an air environment. Cool down to 600°C at a rate of 30°C / min, keep it warm for 5 hours, and then cool to room temperature at a rate of 2°C / min (for the quenching-tempering heat treatment temperature-time curve, see figure 2 ), take out, pulverize and sieve to get 1wt% Al 0.3 Mg 0.3 Ti 0.2 W 0.2 OF 1.5 Coated LCO cathode material, the material structure see image 3 , see the preparation process figure 1 .

[0045] The coated LCO and the uncoated LCO materials were made into positive electrode sheets and coin cells for performance comparison. The positive electrode is composed of: active material: conductive additive: binder = 92:5:3, using Celgard2300 type diap...

Embodiment 2

[0047] 500g of lithium cobaltate (LCO) and 5g of nano-Al 2 o 3 , MgO, ZrO 2 and AlF 3 , WF 6 Put it in a ball mill and mix it thoroughly for 2 to 3 hours. The ratio of metal elements added to the five materials is 2:3:2:1:2. After mixing evenly, keep it in an atmosphere furnace at 800°C for 12h, and then heat it at a speed of 30°C / min. Cool down to 550°C and keep it for 6 hours, then cool to room temperature at a rate of 2°C / min, take it out, pulverize and sieve to get 1wt% Al 0.3 Mg 0.3 Zr 0.2 W 0.2 OF 1.5 Coated LCO cathode material.

Embodiment 3

[0049] Spread 1g of lithium cobalt oxide (LCO) on the substrate, with Al 2 o 3 , MgO, ZrO 2 and NbF 5 、TiF 4 as the target, in a vacuum of 10 -2 torr, voltage 24V, and argon atmosphere, depositing for 25 seconds, 16 seconds, 9 seconds, 5 seconds and 17 seconds respectively, depositing different raw materials on the surface of lithium cobalt oxide particles, and then keeping it at 700°C for 5 hours in an argon atmosphere , and then cooled to room temperature at a rate of 25 °C / min, then raised to 450 °C at a rate of 2 °C / min and kept for 4 hours, and then cooled to room temperature at a rate of 2 °C / min to obtain a compound coated Al on LCO 0.3 Mg 0.2 Zr 0.1 Nb 0.1 Ti 0.2 OF cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com