Copper-based bearing pad with toughening interlayer and preparation method of copper-based bearing pad

An intermediate layer and toughening technology, applied in the direction of shafts, bearings, mechanical equipment, etc., can solve the problems of not being able to be firmly bonded, difficult to cast directly on the copper shell, and poor bonding strength, so as to improve the elastic tension and maintain the oil film The effect of pressure and enhanced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a copper-based bearing bush with a toughened intermediate layer, comprising the following steps:

[0032] (1) Prepare the copper shell of the bearing bush and the tin-based bearing alloy;

[0033] (2) Degrease the surface of the copper shell, perform mechanical sandblasting and roughening treatment, and wash with lye to remove surface oil stains and oxide films, then clean it with absolute ethanol, and activate the surface of the copper shell with acid;

[0034] (3) A toughened intermediate layer with a thickness of 30 μm to 100 μm is formed on the inner surface of the treated copper shell, the composition of the toughened intermediate layer is pure nickel, and a pure nickel toughened intermediate layer is added on the copper shell , to avoid the formation of Cu at the bonding interface between the tin-based bearing alloy and the copper shell 6 sn 5 Brittle phase, thereby improving the strength and toughness of the bearing alloy bonding interfac...

Embodiment 1

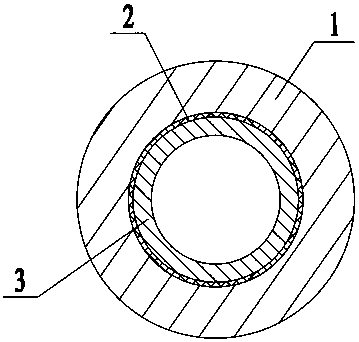

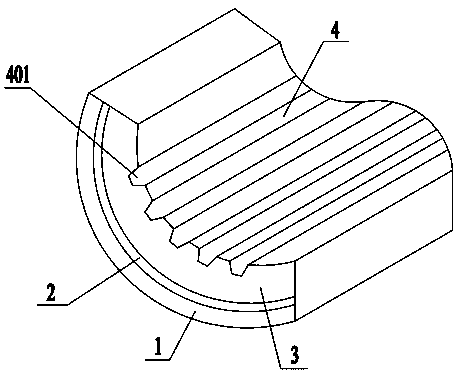

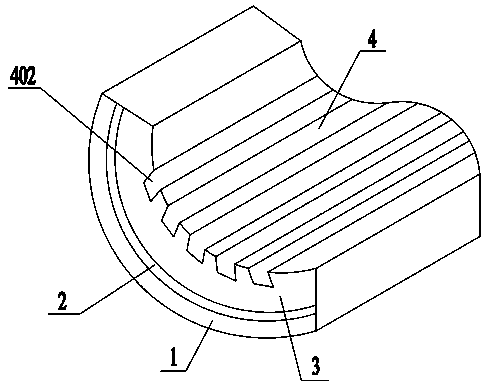

[0044] A copper-based bearing pad with a toughened interlayer, such as figure 1 As shown, it includes a multi-layer structure formed by a copper shell 1, a pure nickel layer 2 and a tin-based bearing alloy layer 3, the copper shell 1 is located on the outer layer of the copper-based bearing bush, and the pure nickel layer 2 is set On the inner wall of the copper shell 1, and form the toughened intermediate layer of the copper-based bearing, the tin-based bearing alloy layer 3 is arranged on the pure nickel layer 2, and form the copper-based bearing inner layer, such as figure 2 As shown, the inner wall of the tin-based bearing alloy layer 3 is provided with uniform grooves 4 , and the grooves 4 are trapezoidal grooves 401 .

[0045] A method for preparing a copper-based bearing bush with a toughened intermediate layer, comprising the following steps:

[0046] (1) Prepare the copper shell of the bearing bush and the tin-based bearing alloy;

[0047] (2) Degrease the surface...

Embodiment 2

[0052] A copper-based bearing pad with a toughened interlayer, such as figure 1 As shown, it includes a multi-layer structure formed by a copper shell 1, a pure nickel layer 2 and a tin-based bearing alloy layer 3, the copper shell 1 is located on the outer layer of the copper-based bearing bush, and the pure nickel layer 2 is set On the inner wall of the copper shell 1, and form the toughened intermediate layer of the copper-based bearing, the tin-based bearing alloy layer 3 is arranged on the pure nickel layer 2, and form the copper-based bearing inner layer, such as figure 2 As shown, the inner wall of the tin-based bearing alloy layer 3 is provided with uniform grooves 4 , and the grooves 4 are trapezoidal grooves 401 .

[0053] A method for preparing a copper-based bearing bush with a toughened intermediate layer, comprising the following steps:

[0054] (1) Prepare the copper shell of the bearing bush and the tin-based bearing alloy;

[0055] (2) Degrease the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com