COG (Chip On Glass) bonding method and temperature control device

A technology of temperature control equipment and binding area, which is applied in the direction of temperature control, optics, and instruments using electric methods, which can solve the problems of temperature contradiction, inability to detect, and inability to obtain expansion, so as to eliminate internal stress and improve quality. , the effect of a good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

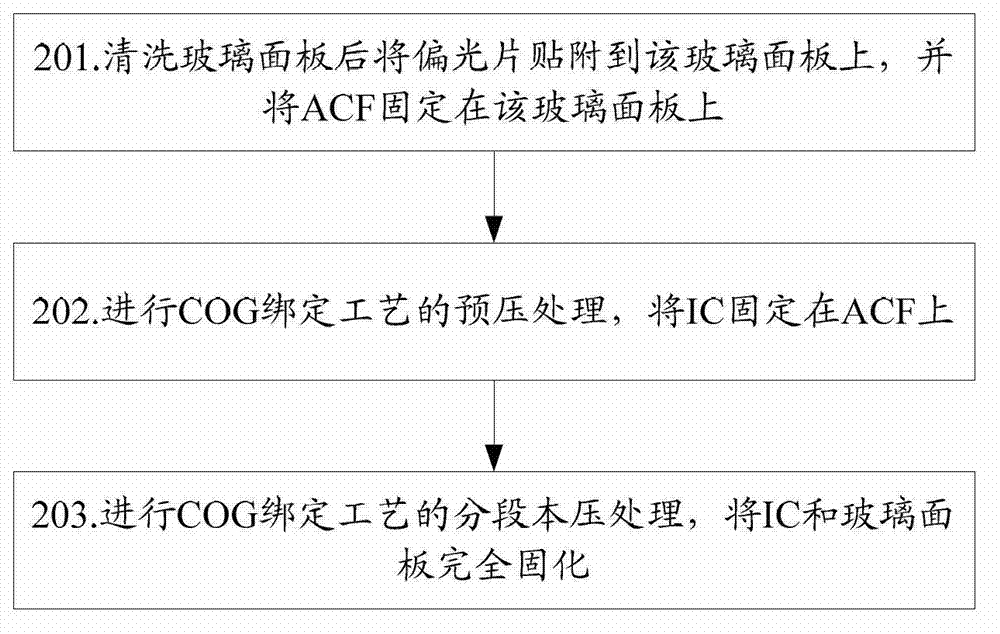

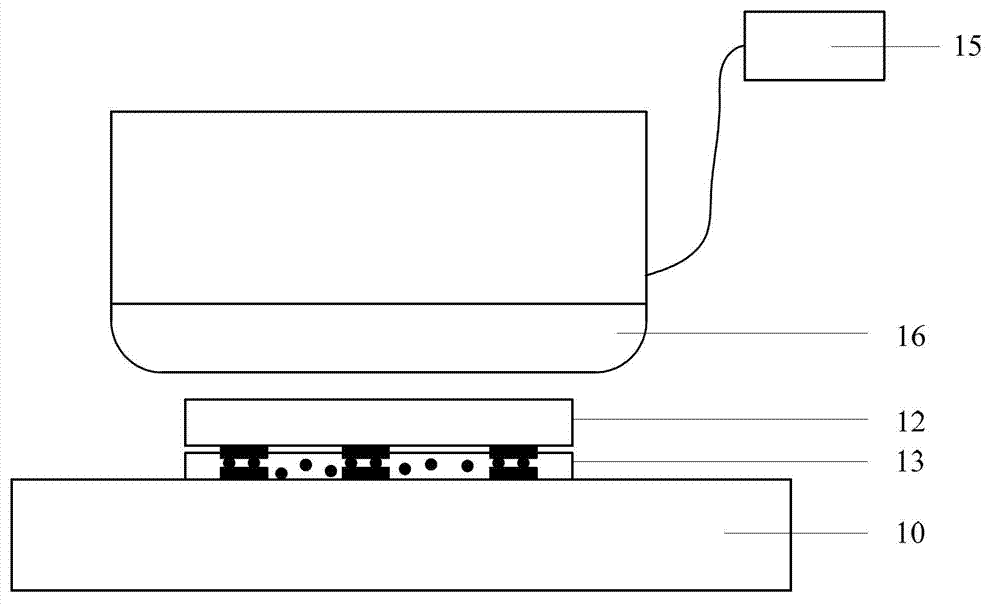

[0027]The basic idea of the present invention is: after cleaning the glass panel, attach the polarizer to the glass panel, and fix the ACF on the glass panel; carry out the pre-pressing treatment of the COG binding process, and fix the IC on the glass panel On the ACF: carry out the staged pressure treatment of the COG bonding process to completely cure the IC and the glass panel.

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0029] The invention provides a COG binding method, figure 2 It is a schematic flow diagram of the method for realizing COG binding in the present invention, such as figure 2 As shown, the method includes the following steps:

[0030] Step 201, after cleaning the glass panel, attach the polarizer to the glass panel, and fix the ACF on the glass panel;

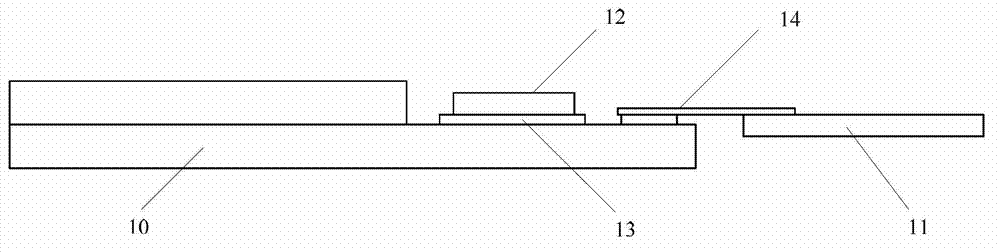

[0031] Specifically, the glass panel 10 is first cleaned to remove foreign matter on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com