Packaging method for board level fan-out structures

A packaging method and fan-out technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of mechanical warpage manufacturing efficiency of board-level fan-out structure, low board-level fan-out structure, etc., to ensure quality and performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

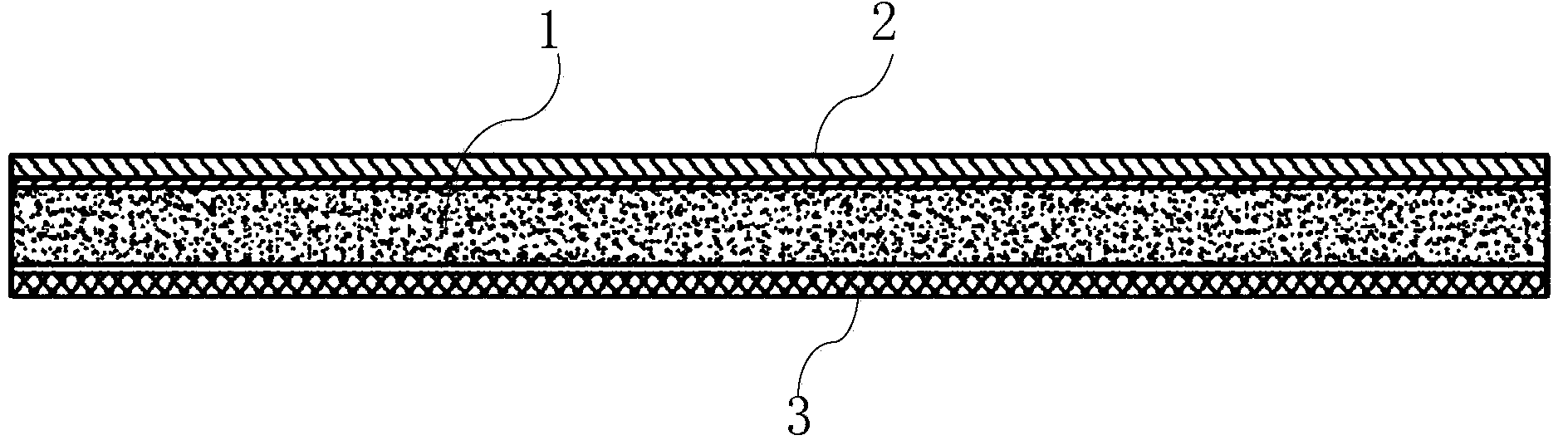

[0029] see figure 1 , an embodiment of the present invention provides a packaging method for a board-level fan-out structure, including:

[0030] Step 1: See figure 1 , press the first double-layer copper foil 2 on the upper side of the core board 1 (using prepreg or double-sided copper-clad organic substrate), and press the second double-layer copper foil 3 on the lower side of the core board 1; The layer copper foil 2 and the second double-layer copper foil 3 are peelable structures. The thickness of the outer layer copper foil in the first double layer copper foil 2 is greater than the thickness of the inner layer copper foil; the thickness of the outer layer copper foil in the second double layer copper foil 3 is greater than the thickness of the inner layer copper foil.

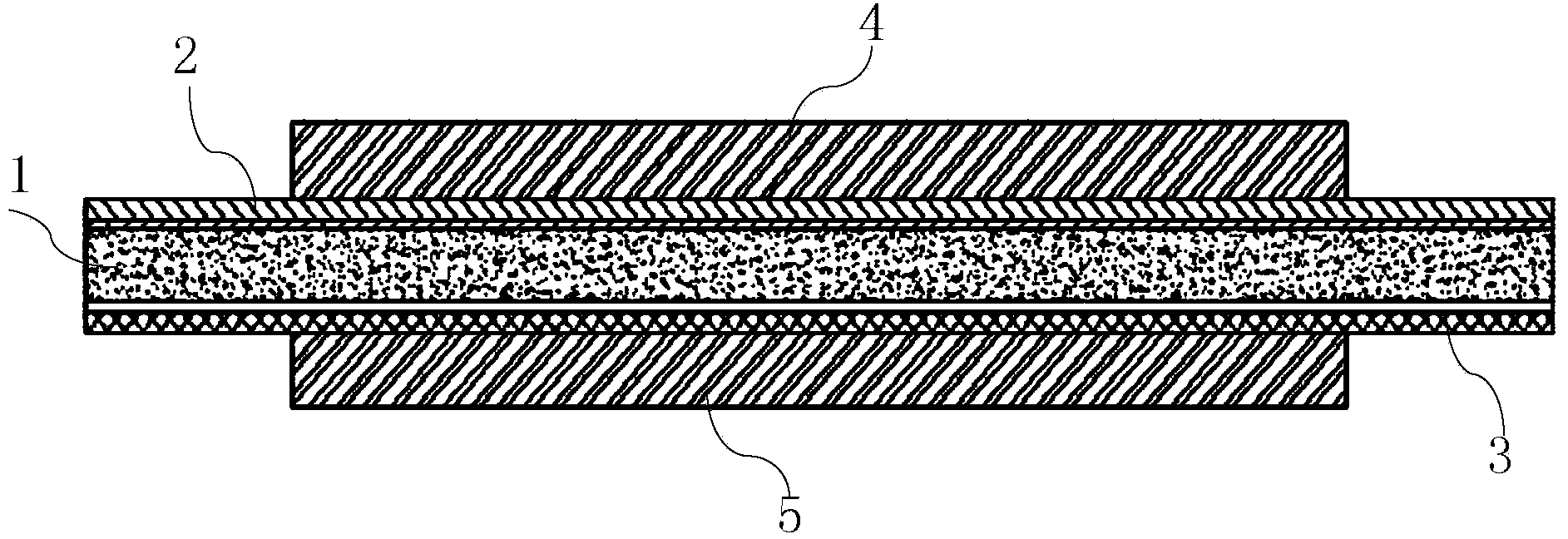

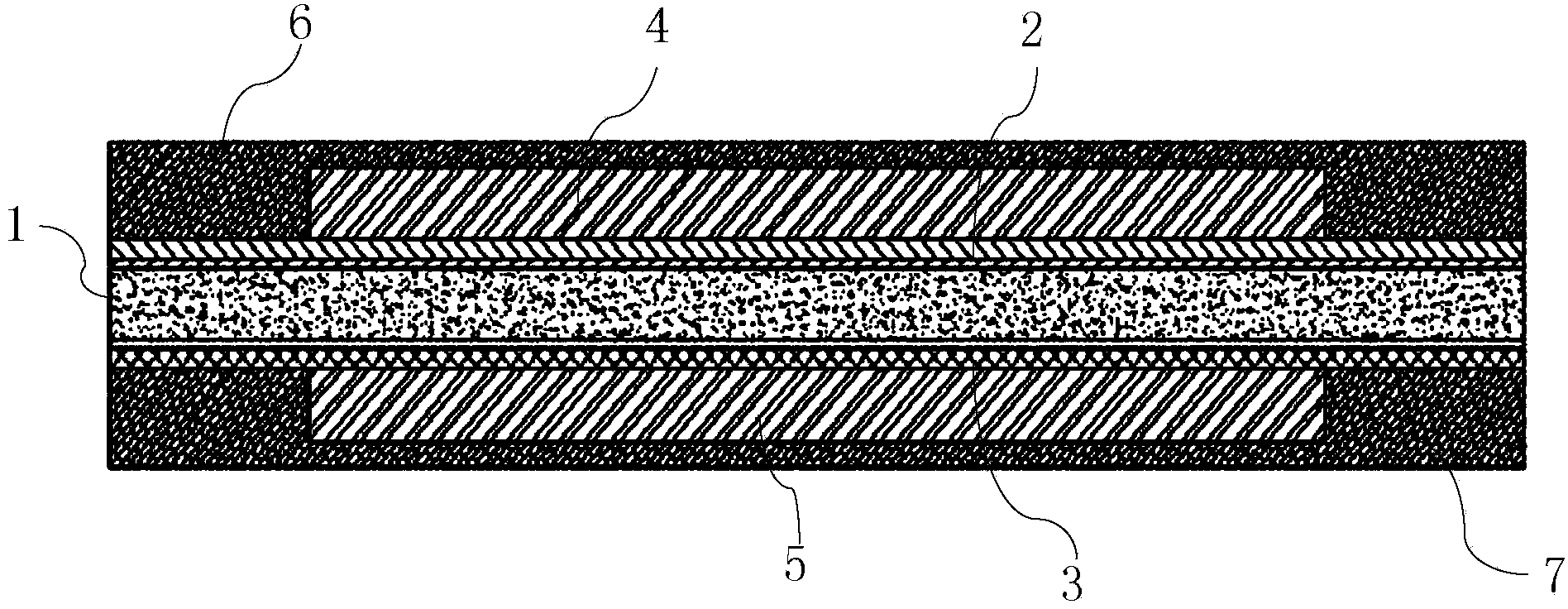

[0031] Step 2: See figure 2 The first chip 4 is mounted on the outside of the first double-layer copper foil 2, the second chip 5 is mounted on the outside of the second double-layer copper foil 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com