Smelting method of nitrogen-containing high-strength steel 32AB5

A 32AB5, smelting method technology, applied in the field of iron and steel metallurgy, can solve the problems of not being able to accurately control the smelting method of nitrogen-containing high-strength steel, narrow, and high production difficulty, and achieve the effects of low production cost, simple production process, and guaranteed quality and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

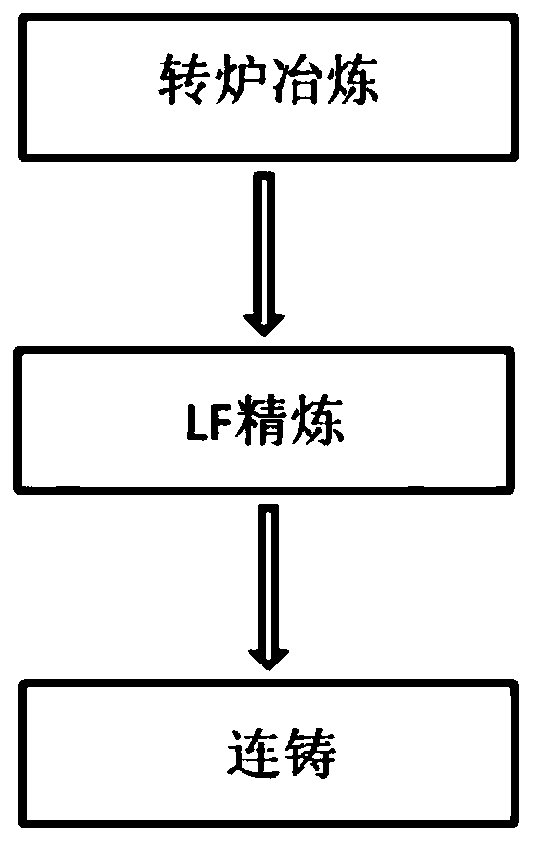

Method used

Image

Examples

Embodiment 1

[0043] In the embodiment of the present invention, the nitrogen-containing high-strength steel 32AB5 is produced by using semi-steel after vanadium-containing titanium hot metal extracting vanadium and desulfurization as raw material, wherein, the semi-steel contains 3.51% C, 0.040% Mn, 0.063% by mass percentage. % of P, 0.007% of S, 0.03% of V and traces of Cr, Si and Ti, the balance being iron and unavoidable impurities.

[0044] Specific steps:

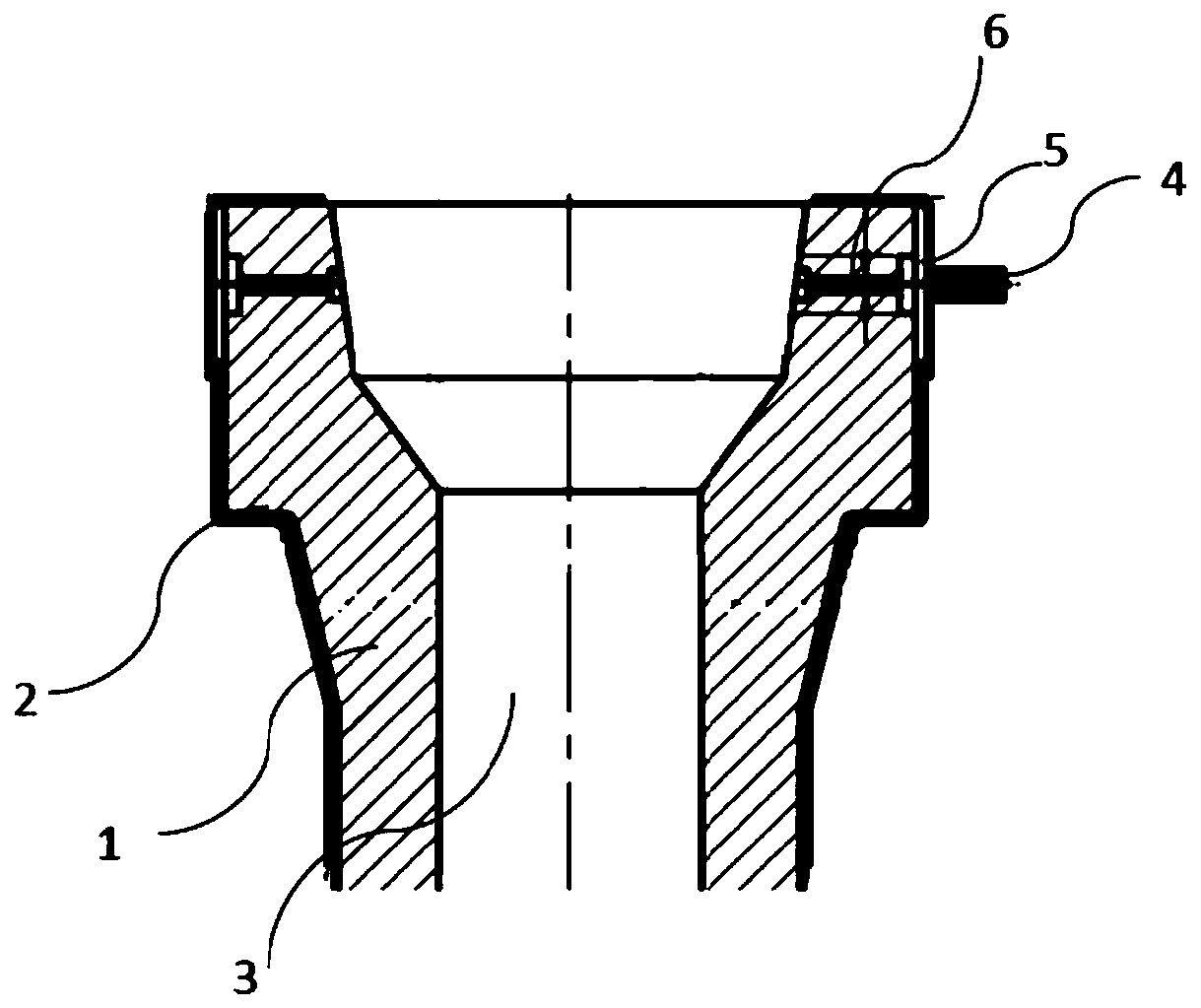

[0045] (1) Converter primary smelting process: Add 235 tons of the above-mentioned semi-steel into a 200-ton (nominal capacity) top-bottom double-blowing converter, and use the function of the top-bottom double-blowing converter to decarburize the above-mentioned semi-steel into molten steel. During the initial smelting process of the converter, argon gas is blown to the breathable bricks at the bottom of the converter throughout the whole process to ensure that the gas supply flow rate of a single brick reaches 50m 3 / h, the argo...

Embodiment 2

[0051] Embodiment 2 is the same as Embodiment 1 except that the tapping time of the converter primary smelting process is 5 minutes.

[0052] The chemical composition of the finished product of this embodiment is: C content is 0.055wt%, Si content is 0.03wt%, Mn content is 0.20wt%, P content is 0.009wt%, S content is 0.008wt%, Als content is 0.015wt%, The N content is 0.0025 wt%, and the Ti content is 0.005 wt%.

[0053] The properties of the rolled material obtained in this embodiment are as follows: yield strength 293MPa, tensile strength 389MPa, BH2 37.

Embodiment 3

[0055] Example 3 is the same as Example 1 except that the LF refining time is 30 minutes.

[0056] The chemical composition of the finished product in this embodiment is: C content is 0.065wt%, Si content is 0.045wt%, Mn content is 0.23wt%, P content is 0.012wt%, S content is 0.012wt%, Als content is 0.030wt%, The N content is 0.0032 wt%, and the Ti content is 0.010 wt%.

[0057] The properties of the rolled material obtained in this embodiment are as follows: yield strength 294MPa, tensile strength 386MPa, BH2 37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com