Double-glass component lamination system

A double-glass module, lamination technology, applied in the direction of lamination, lamination device, control lamination, etc., can solve the problems of water leakage at the edge of the module, the shape of the back glass springs back, and cannot be widely used, so as to ensure the quality and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

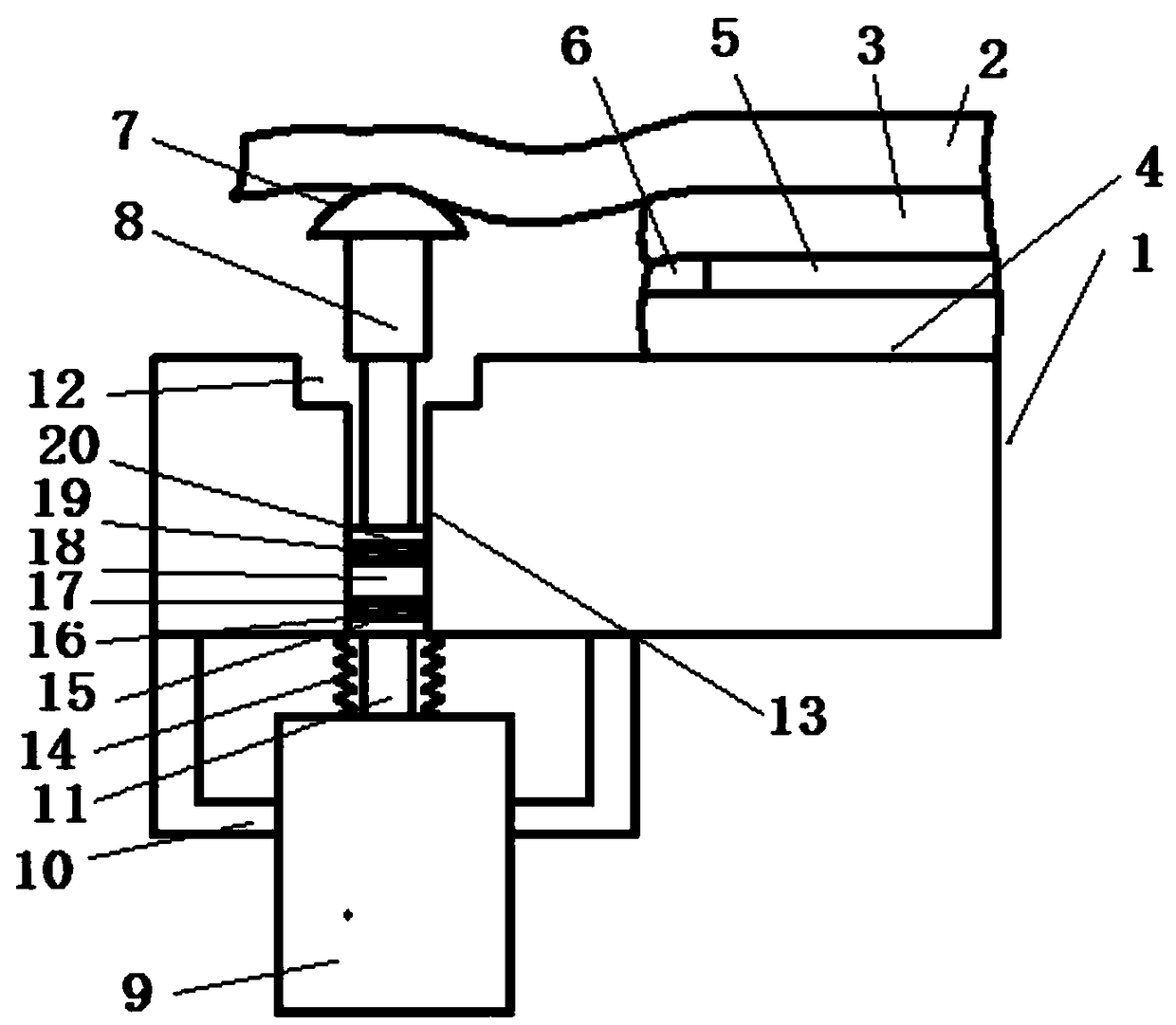

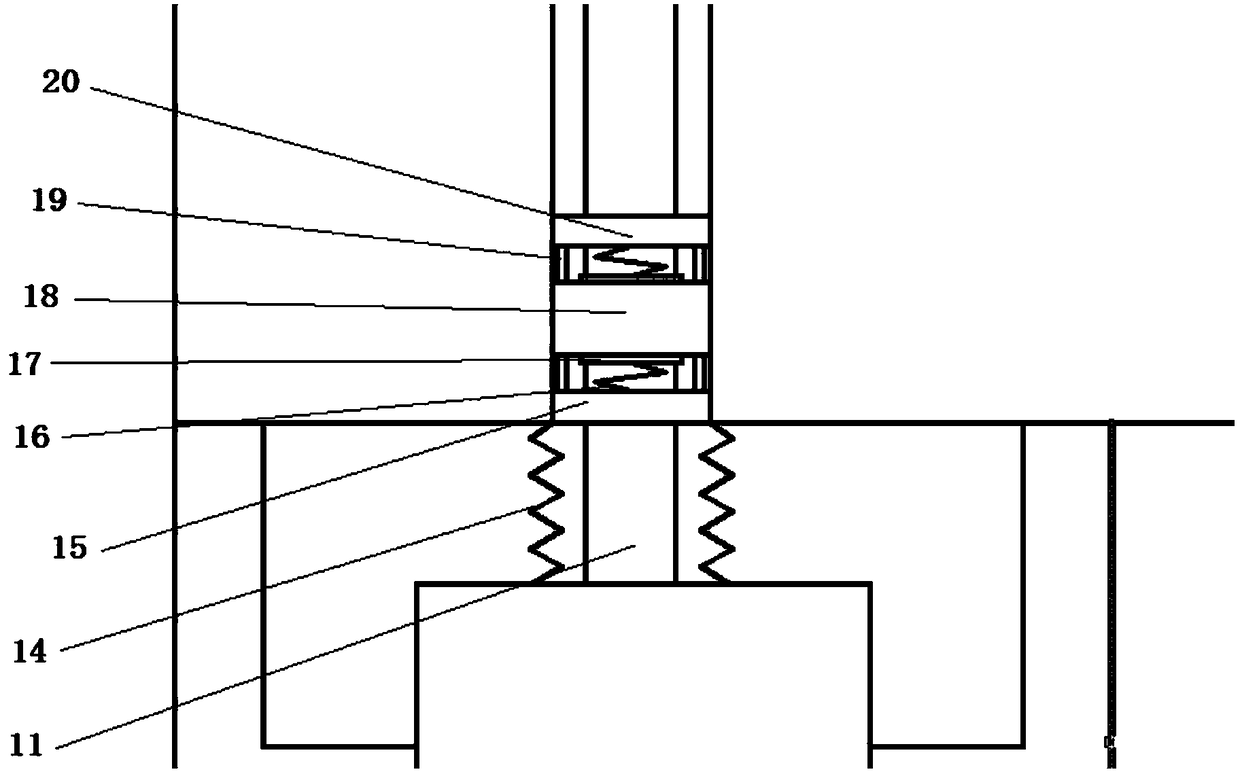

[0023] Such as figure 1 and figure 2 As shown, the application provides a double-glass module lamination system, which includes a laminator heating plate 1, a laminator silica gel plate 2, wherein the double-glass battery assembly is arranged on the laminator heating plate 1 and the laminator Between the silica gel plates 2, the double-glass battery assembly includes the back glass 3 and the battery substrate 4, there is an encapsulation film 5 between the back glass 3 and the battery substrate 4, and butyl glue is coated on the edge of the encapsulation film 5 6. Since the silicone plate of the laminator is covered on the back glass, the edge of the back glass is prone to overvoltage abnormality, and the back glass is slightly deformed, resulting in a thin edge of the double-glass battery module. In the subsequent reliability test, it is easy to occur The shape of the glass on the back bounces back, causing abnormal water leakage at the edge of the component. In order to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com