Vacuum infusion process of large winding in soft mold

A vacuum impregnation and coil technology, applied in coil manufacturing and other directions, to achieve the effect of eliminating internal stress, solving uneven fiber density, and reducing processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

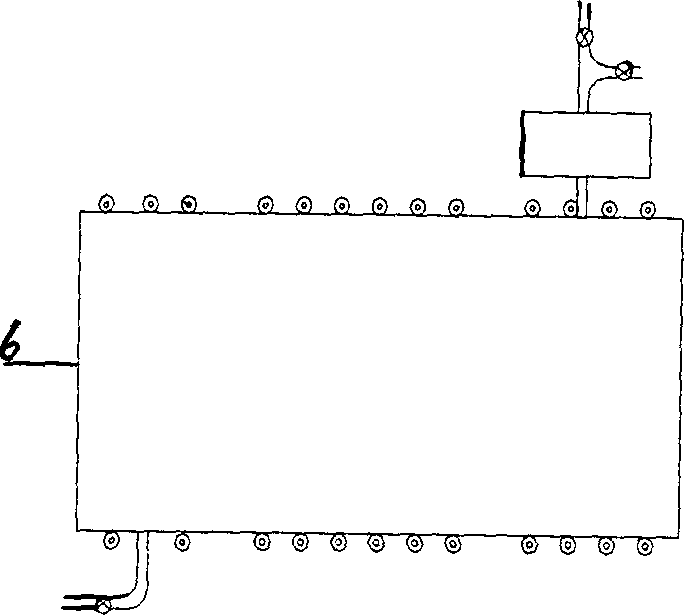

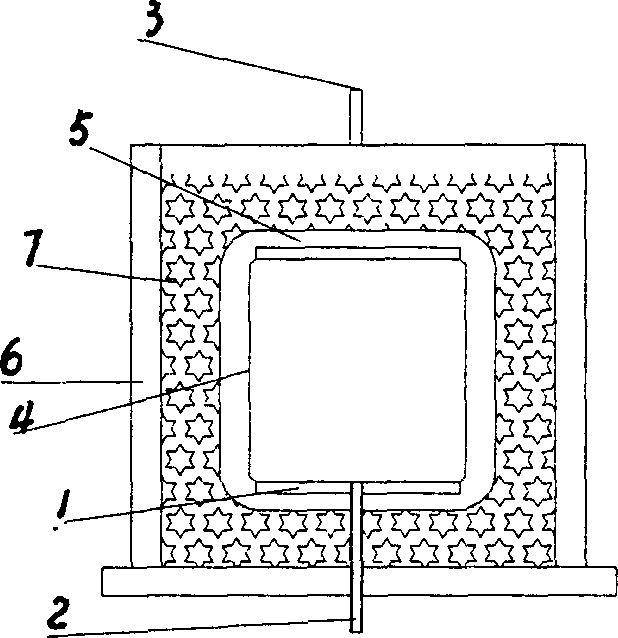

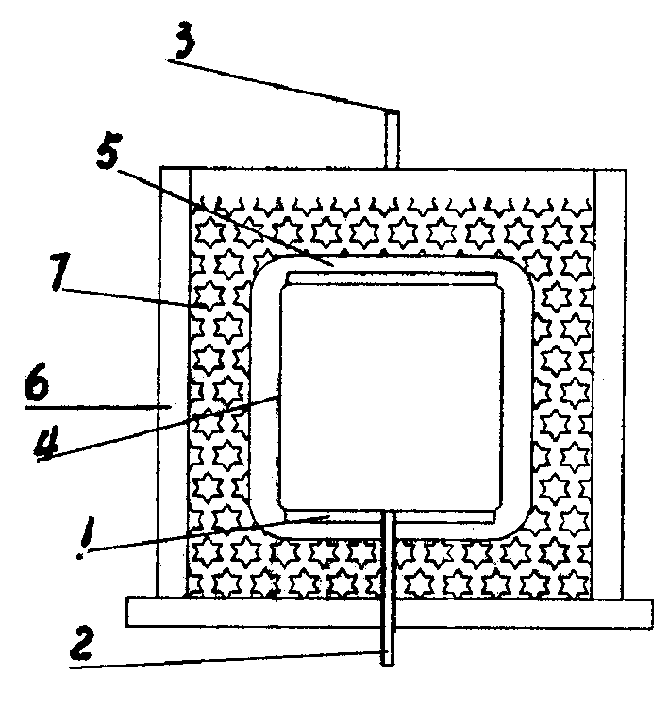

[0025] see figure 1 , 2 , The vacuum impregnation process of the large coil soft mold is to first install the deflector 1, the injection port 2 and the plastic discharge port 3. The glue injection port is installed on the lower deflector, the glue outlet is installed on the upper deflector, and the upper and lower deflectors are respectively close to the upper and lower sides of the coil, and are fixed by half-folded wrapping of tetrafluoroethylene tape. The second step is to combine the deflector with the coil, and to wrap the self-dissolving sealing tape 5, that is, to wrap one and a half layers of the self-dissolving silicon rubber sealing tape on the tetrafluoroethylene tape. The third step is to brush liquid vulcanized silicone rubber on the outside of the self-dissolving sealing tape to form a sealing cavity. The fourth step is to vacuumize and repair leaks, that is, after the liquid vulcanized silicone rubber is cured, close the glue injection port, and vacuumize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com