LED package structure and method for manufacturing the same

A technology for light-emitting diodes and packaging structures, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of low light extraction efficiency of light-emitting diodes and reduction of total light reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

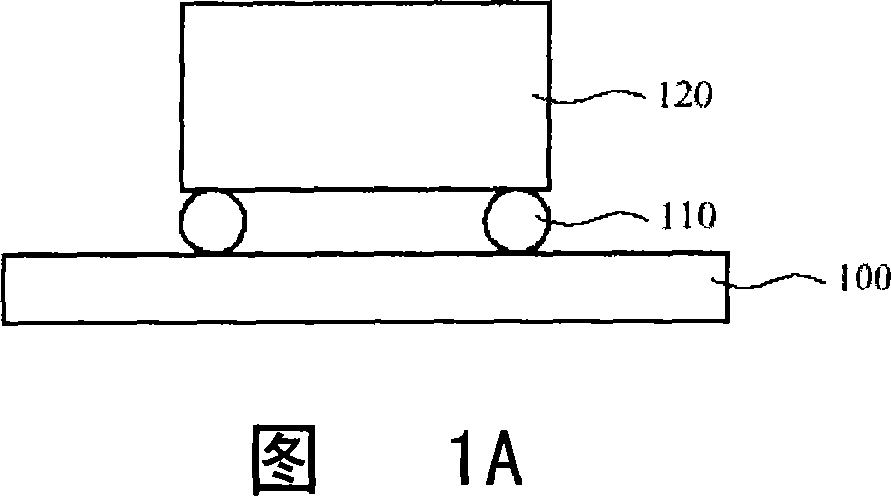

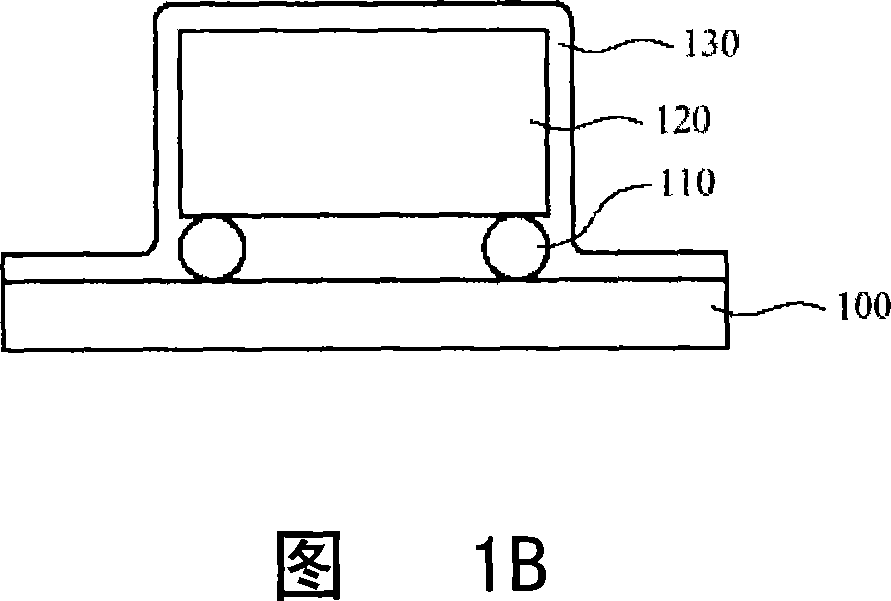

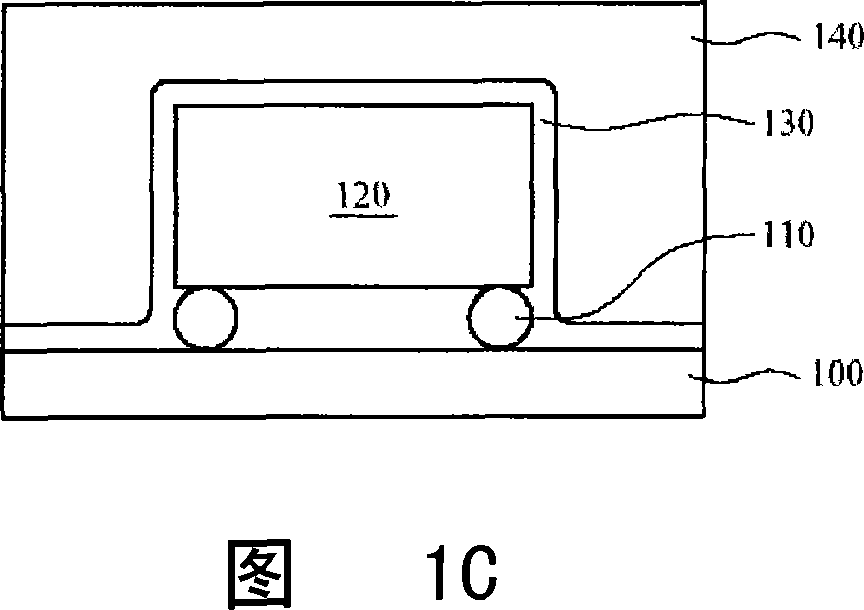

[0015] Please refer to FIG. 1A to FIG. 1C , which are schematic cross-sectional views of the manufacturing process of the LED packaging structure according to a preferred embodiment of the present invention. First, as shown in FIG. 1A , an LED chip 120 is provided, the refractive index of which is between 2.3 and 4. Referring to FIG. In this embodiment, a gallium nitride (GaN) light-emitting element is used, and its refractive index is 2.5. The anode electrode and the cathode electrode (not shown) on the light emitting diode chip 120 are electrically connected to a substrate having multiple contacts, such as the circuit board 100, through the metal bump 110 in a flip-chip manner; another option Yes, the LED chip 120 can also be electrically connected to the circuit board 100 by wire bonding. Next, as shown in FIG. 1B , a plasma chemical vapor deposition layer 130 is conformally formed on the LED chip 120 , wherein the refractive index of the plasma chemical vapor deposition l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com