Ephedra extract stripped of ephedrine alkaloids, method for producing same and use of same

An alkaloid and ephedra technology, applied in the field of ephedra alkaloid-removing ephedra extract, can solve problems such as difficulty in ephedra separation, and achieve high pain-inhibiting effect and pain-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The extraction step of ephedra performed in the production method of the present invention can be performed based on any of the well-known methods. As the extraction solvent, other organic solvents such as water, warm water, hot water, alcoholic solvents, and acetone can be used. Examples of alcohol-based solvents include methanol, ethanol, propanol, isopropanol, butanol, isobutanol, and the like. These solvents may be used alone or in combination.

[0057] The amount of the extraction solvent is preferably 2-100 parts by weight relative to the dry weight of ephedra. The extraction temperature is preferably 4-98°C. The extraction time is preferably 30 minutes to 2 hours. The extraction method can be performed by any method such as stirring extraction, immersion extraction, convection extraction, ultrasonic extraction, supercritical extraction and the like.

[0058] The obtained extract, the filtrate obtained by filtering the extract, the concentrate obtained by conc...

Embodiment 1

[0094] Embodiment 1: the making of ephedra extract.

[0095] The dry raw material of ephedra was pulverized by a mixer, and 500 mL of water was added to 50 g of the pulverized product, and extracted at 95° C. for 1 hour while stirring. Solid-liquid separation was performed, and the extract was centrifuged at 3000 rpm for 10 minutes. The obtained supernatant was concentrated under reduced pressure at 60° C., and then dried under reduced pressure at 60° C. overnight to obtain 9.6 g of ephedra extract.

Embodiment 2

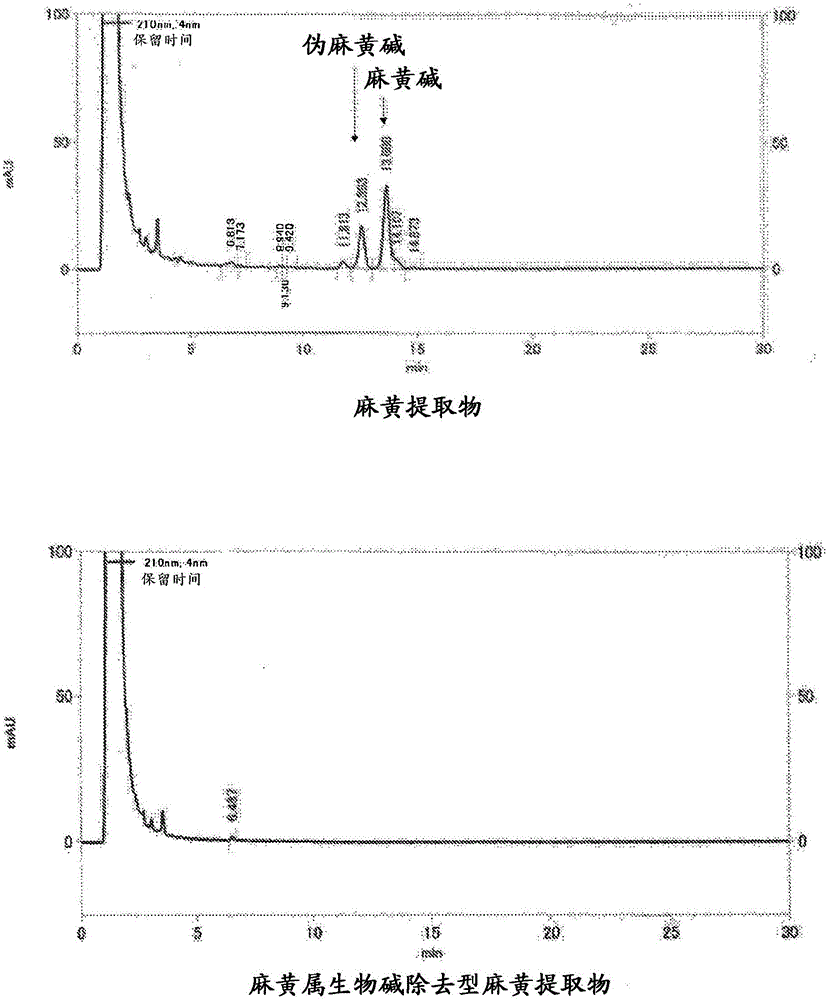

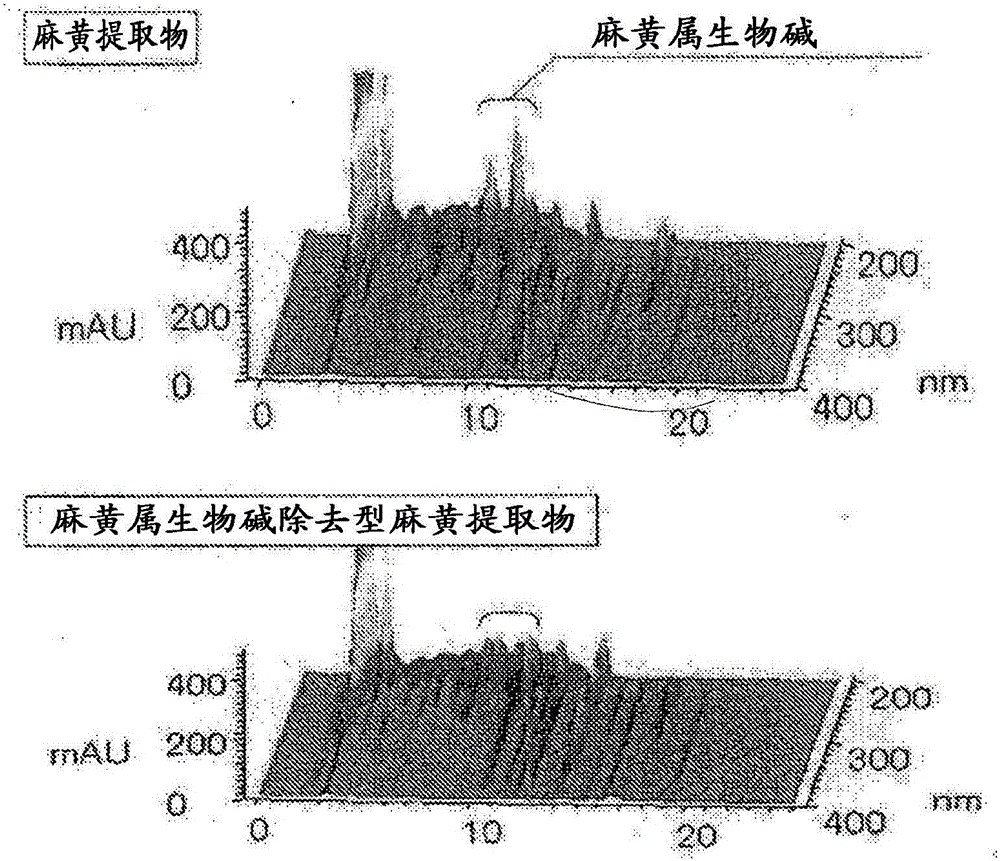

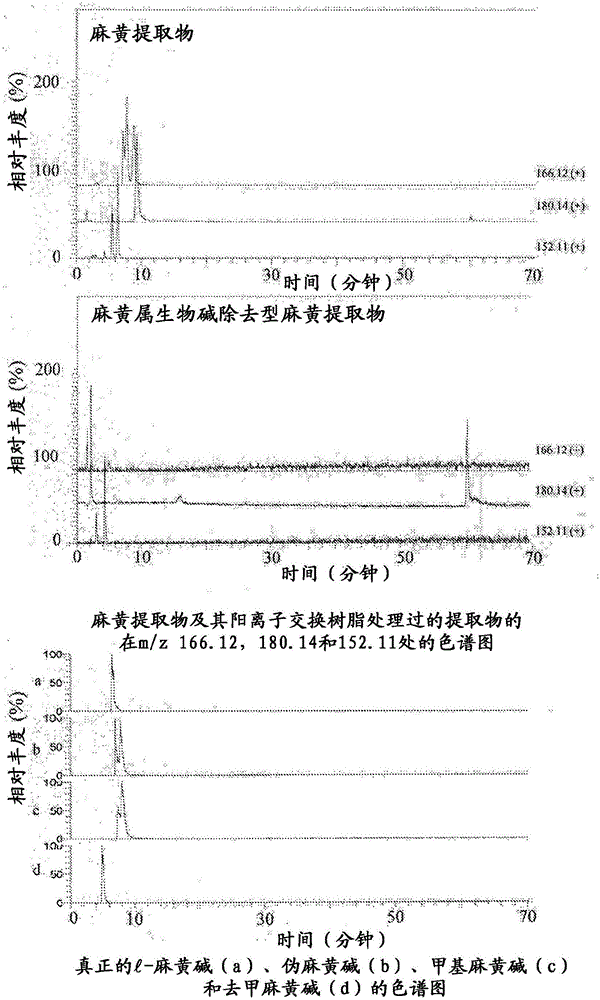

[0096] Example 2: Production of ephedra alkaloid-removing ephedra extract by ion exchange resin SK1B.

[0097] The dry raw material of ephedra was pulverized by a mixer, and 500 mL of water was added to 50 g of the pulverized product, and extracted at 95° C. for 1 hour while stirring. Solid-liquid separation was performed, and the extract was centrifuged at 3000 rpm for 10 minutes, and the obtained supernatant was passed through 25 mL of strong-acid cation exchange resin SK1B (manufactured by Mitsubishi Chemical). Dilute the passage solution with 5% NaHCO 3 Adjusted to pH = 5.2, concentrated under reduced pressure at 60° C., and dried under reduced pressure at 60° C. overnight to obtain 6.3 g of an alkaloid-removing ephedra extract of the genus Ephedra.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com