A method for preparing ultrafine antimony oxides by solution atomization

A technology of antimony oxide and solution atomization, which is applied in chemical instruments and methods, antimony compounds, antimony oxide/antimony hydroxide/antimony oxyacid, etc., can solve the problems of large equipment investment and long preparation process, and achieve Requires simple, uniform and fine particles, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of method that the solution atomization method of the present invention prepares superfine antimony oxide, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0059] (1) Weigh 50.00g SbCl 3 Solid, add 4.5mol / L hydrochloric acid solution diluted with pure water to prepare 0.55mol / L SbCl 3 solution;

[0060] (2) utilize ozone gas to above-mentioned SbCl 3 The solution is oxidized and the potential of the solution is detected. When the potential of the solution is about 0.75V, the ozone is stopped;

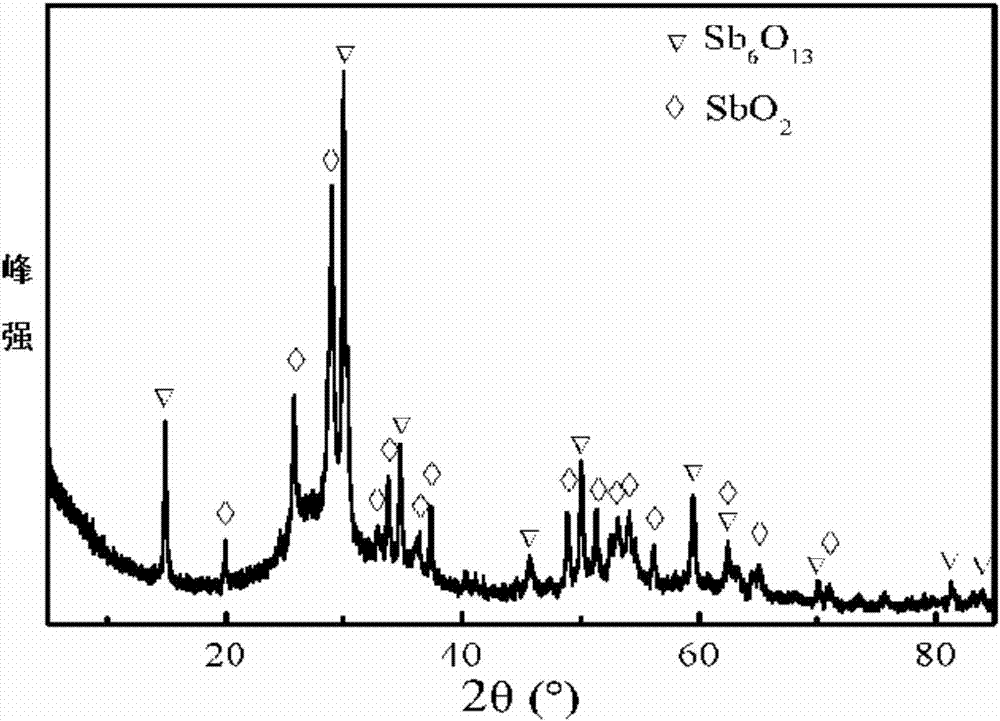

[0061] (3) Use an ultrasonic atomizer to atomize the above-mentioned oxidized solution and control the atomization flow rate to 30mL / h, and use a vacuum pump to draw negative pressure on the reaction device, so that the atomized solution enters the vertical tubular resistance furnace, Thermal decomposition reaction is carried out at a temperature of 500°C to obtain antimony oxide powder;

[0062] (4) The antimony ...

Embodiment 2

[0066] A kind of method that the solution atomization method of the present invention prepares superfine antimony oxide, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0067] (1) Prepare 400mL of 5.0mol / L hydrochloric acid in a beaker, heat it in a water bath to the set temperature, then weigh 40.00g of stibnite and add it to the beaker. During the experiment, use a magnetic stirrer to stir and control the stirring speed to extract During the process, continuously feed ozone gas into the solution, react for 4 hours, and filter to obtain the leachate after the reaction is completed;

[0068] (2) Utilize ozone gas to carry out oxidation operation to above-mentioned leaching liquid solution and detect solution potential, when solution potential is about 0.75V, stop feeding ozone;

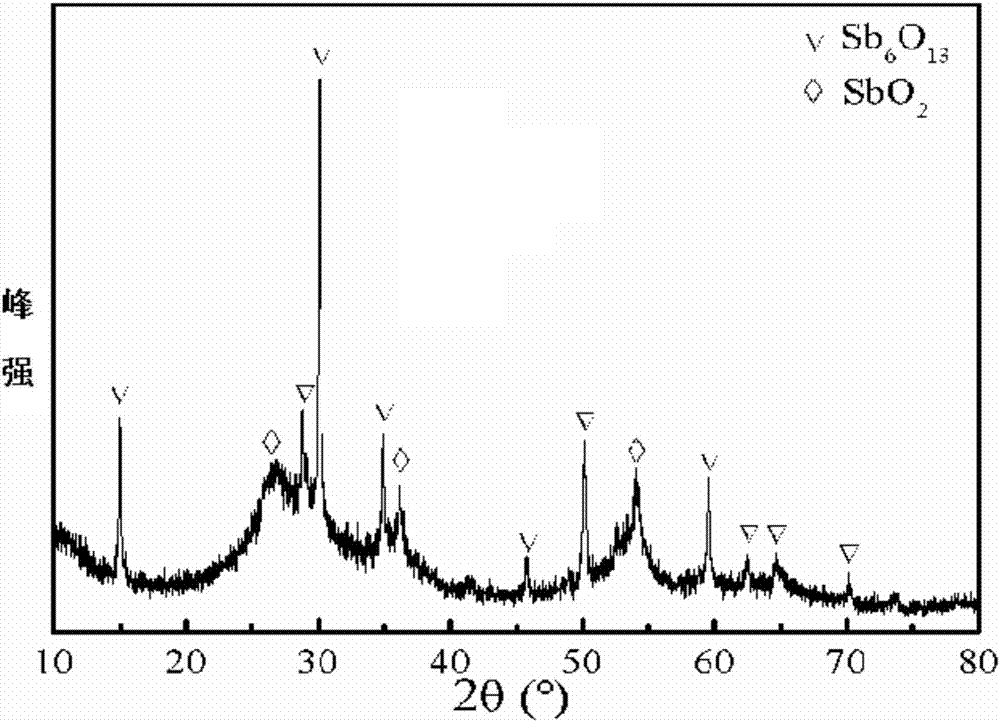

[0069] (3) Use an ultrasonic atomizer to atomize the above-mentioned oxidized solution and control the atomization flow rate to be 50mL / h, and ...

Embodiment 3

[0074] A kind of method that the solution atomization method of the present invention prepares superfine antimony oxide, its process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0075] (1) Weigh 50.00g SbCl 3 Solid, added to the 4.5mol / L hydrochloric acid solution diluted with pure water to prepare 0.55mol / L SbCl 3 solution;

[0076] (2) Use oxygen gas to treat the above-mentioned SbCl 3 The solution is oxidized and the potential of the solution is detected. When the potential of the solution is about 0.75V, stop feeding oxygen;

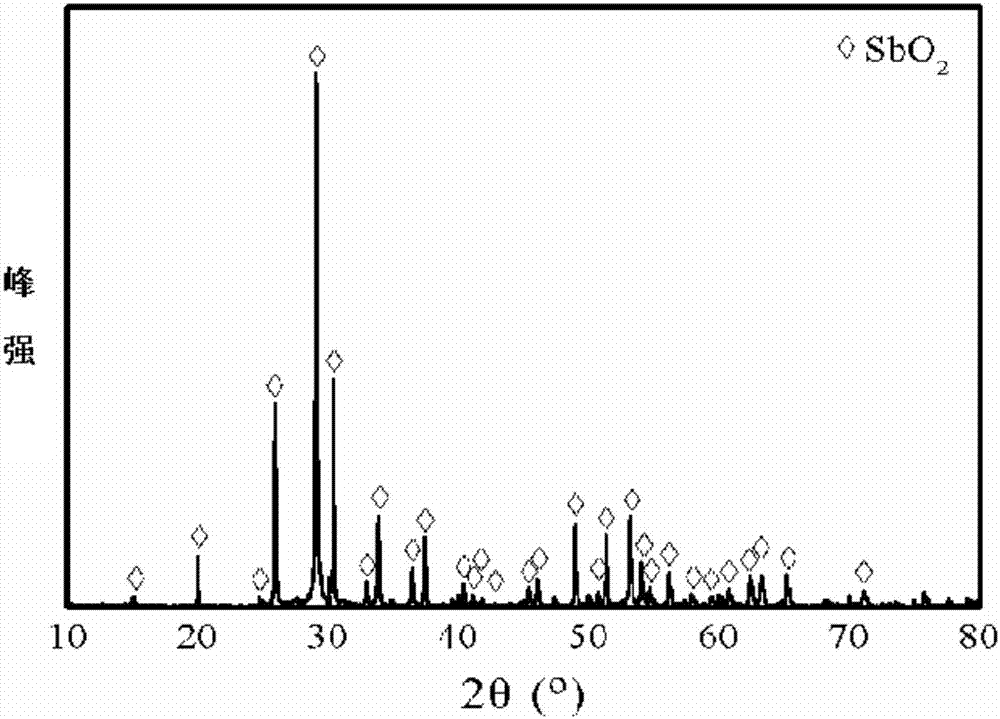

[0077] (3) Use an ultrasonic atomizer to atomize the above-mentioned oxidized solution and control the atomization flow rate to 50mL / h, and use a vacuum pump to draw negative pressure on the reaction device, so that the atomized solution enters the vertical tubular resistance furnace. Perform thermal decomposition reaction at a temperature of 900°C to obtain antimony oxide powder;

[0078](4) The an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com