Novel prefabricated type steel-concrete composite beam bridge upper structure and manufacturing technology thereof

A prefabricated assembly and manufacturing process technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of reducing the service life of steel bridge decks, prone to fatigue cracks, and prone to corrosion, etc., to shorten the replacement period and ease traffic Stress, mass-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

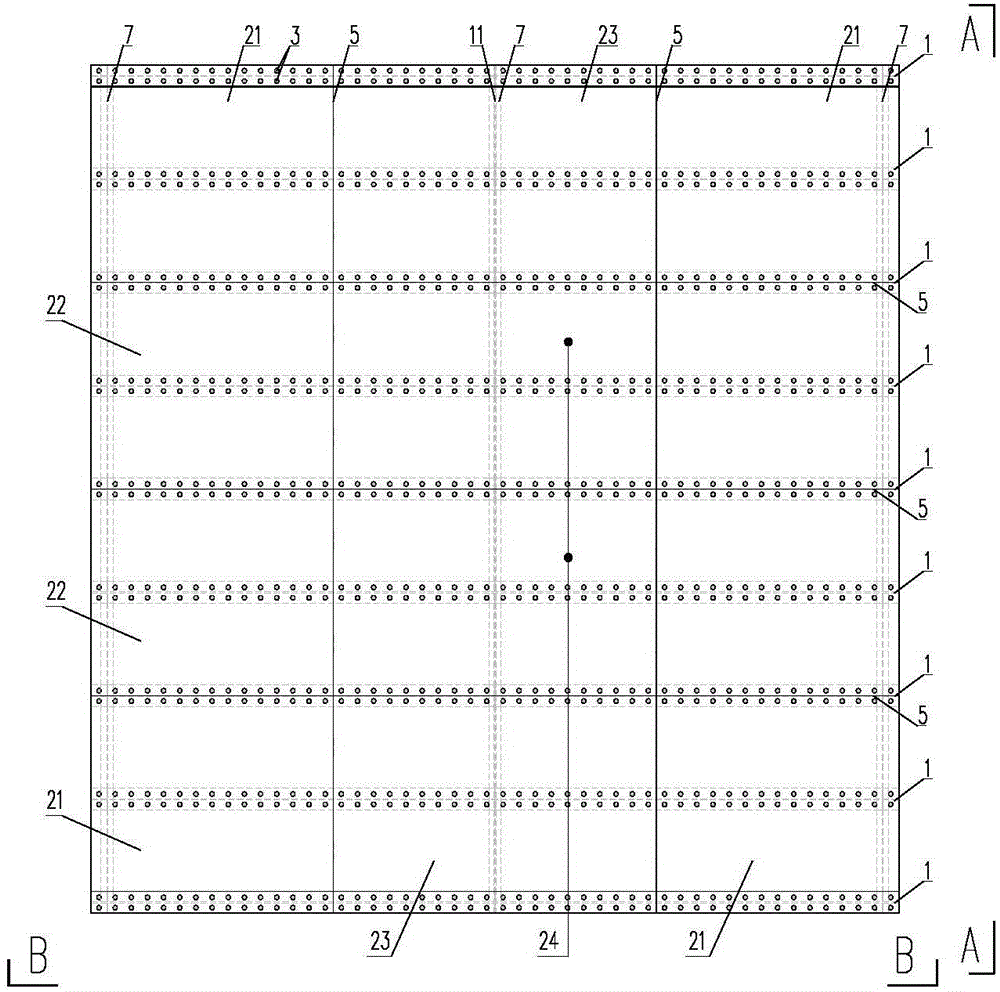

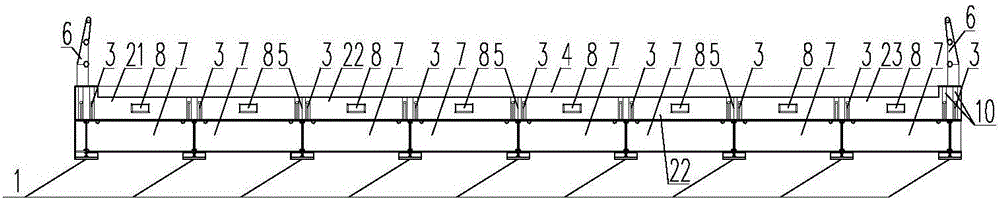

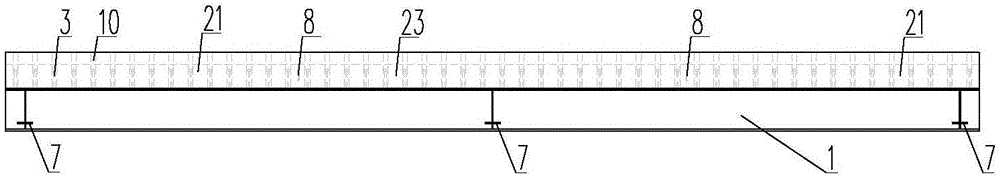

[0037] refer to Figure 1 to Figure 5 , a novel prefabricated assembled steel-concrete composite girder bridge superstructure, comprising a steel main girder 1, a transverse connecting steel girder 7, metal connectors 3 and a prefabricated reinforced concrete bridge deck, the steel main girder 1 being constructed according to the shape of the bridge Arranged, the webs of adjacent steel girders 1 are connected by transverse connecting steel girders 7, the upper flange of the steel girders 1 is provided with the metal connector 3, and the prefabricated reinforced concrete bridge deck is laid on On the upper flange of the steel girder 1, the prefabricated reinforced concrete bridge deck is provided with a reserved hole 10 for pouring grouting material after the bridge deck is installed, and the metal connector 3 is located in the reserved hole within 10.

[0038] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com