U-shaped seamless nickel-chromium iron alloy heat transfer tube for nuclear steam generator

A steam generator, seamless nickel-chromium technology, applied in the field of seamless tube heat transfer tubes and their manufacturing, can solve the problems of restricting the development scale and speed of the nuclear power industry, high product prices, long delivery times, etc. Chromium depletion phenomenon, improved stress resistance and intergranular corrosion resistance, long length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

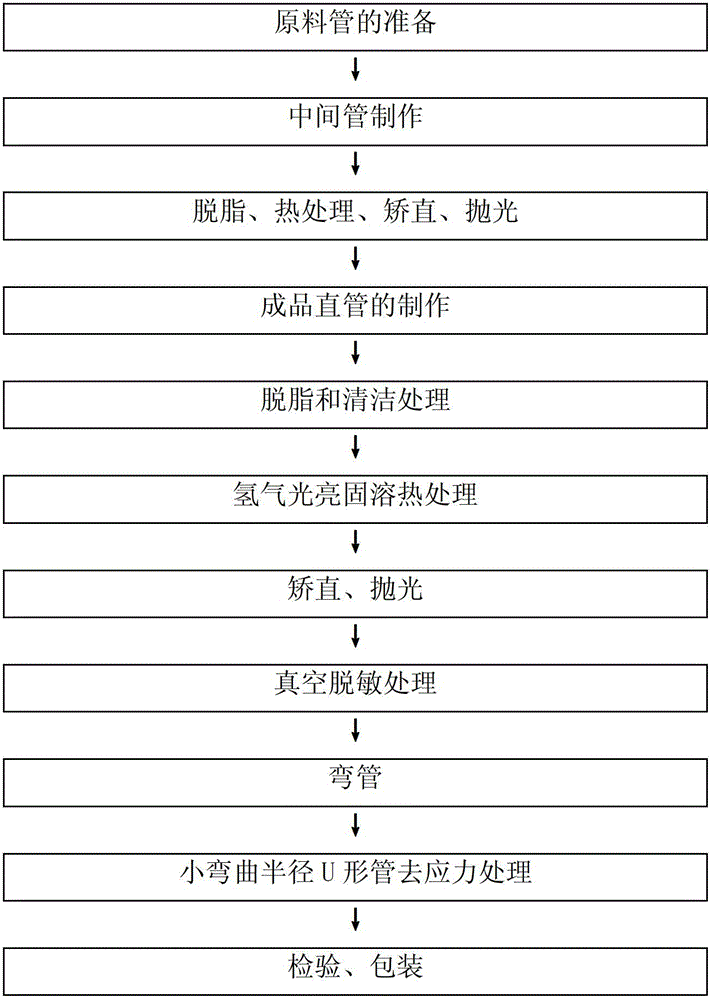

[0034] This embodiment provides a U-shaped seamless nickel-chromium-iron alloy heat transfer tube for a nuclear power steam generator, and the process is as follows figure 1 shown, proceed as follows:

[0035] (1) Preparation of the raw material pipe, the chemical composition and mass percentage of the raw material pipe are: Ni: 58%, Cr: 31%, Fe: 9%, C: 0.01-0.03%, 0<Si≤0.5%, 0<Mn≤0.5 %, 0<S≤0.01%, 0<P≤0.015%, 0<Cu≤0.05%, 0<Co≤0.016%, 0<Ti≤0.5%, 0<Al≤0.5%, 0<Nb≤0.1% , 0<B≤0.003%, 0<N≤0.05%, the sum of the above components is 100%;

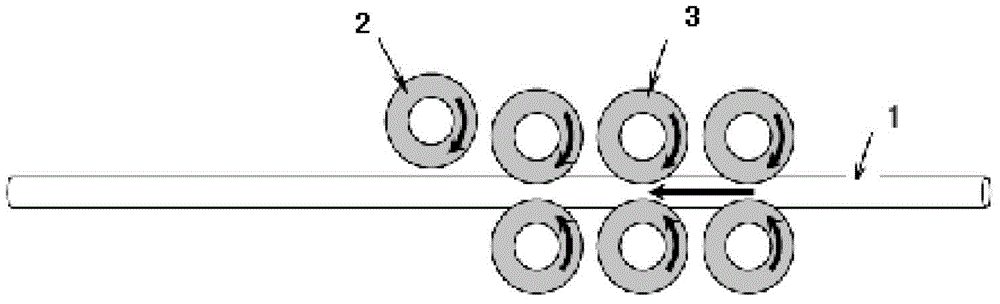

[0036](2) The raw material tube is cold-rolled to an intermediate tube with an outer diameter of 28 mm and a wall thickness of 2.5 mm through cold rolling equipment. The intermediate tube is first degreased and cleaned, and then subjected to a protective atmosphere bright heat treatment, and then straightened successively after the protective atmosphere bright heat treatment and surface grinding treatment; the protective atmosphere uses pure hydr...

Embodiment 2

[0044] This embodiment provides a U-shaped seamless nickel-chromium-iron alloy heat transfer tube for a nuclear power steam generator, and the process is as follows figure 1 shown, proceed as follows:

[0045] (1) Preparation of the raw material pipe, the chemical composition and mass percentage of the raw material pipe are: Ni: 62%, Cr: 28%, Fe: 8%, C: 0.01-0.03%, 0<Si≤0.5%, 0<Mn≤0.5 %, 0<S≤0.01%, 0<P≤0.015%, 0<Cu≤0.05%, 0<Co≤0.016%, 0<Ti≤0.5%, 0<Al≤0.5%, 0<Nb≤0.1% , 0<B≤0.003%, 0<N≤0.05%, the sum of the above components is 100%;

[0046] (2) The raw material tube is cold-rolled to an intermediate tube with an outer diameter of 32 mm and a wall thickness of 3.0 mm through cold rolling equipment. The intermediate tube is first degreased and cleaned, and then subjected to a protective atmosphere bright heat treatment, and then straightened successively after the protective atmosphere bright heat treatment and surface grinding treatment; the protective atmosphere uses pure hyd...

Embodiment 3

[0054] This embodiment provides a U-shaped seamless nickel-chromium-iron alloy heat transfer tube for a nuclear power steam generator, and the process is as follows figure 1 shown, proceed as follows:

[0055] (1) Preparation of the raw material pipe, the chemical composition and mass percentage of the raw material pipe are: Ni: 59%, Cr: 29%, Fe: 11%, C: 0.01-0.03%, 0<Si≤0.5%, 0<Mn≤0.5 %, 0<S≤0.01%, 0<P≤0.015%, 0<Cu≤0.05%, 0<Co≤0.016%, 0<Ti≤0.5%, 0<Al≤0.5%, 0<Nb≤0.1% , 0<B≤0.003%, 0<N≤0.05%, the sum of the above components is 100%;

[0056] (2) The raw material pipe is cold-rolled to an intermediate pipe with an outer diameter of 38mm and a wall thickness of 3.5mm by cold rolling equipment. The intermediate pipe is first degreased and cleaned, and then subjected to bright heat treatment in a protective atmosphere, and then straightened successively after the bright heat treatment in a protective atmosphere and surface grinding treatment; the protective atmosphere uses pure h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com