Method for welding foamed aluminum material by transient liquid phase diffusion

A diffusion welding and instantaneous liquid phase technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of unfavorable interface layer component diffusion and uniform solidification, material Strength and plastic failure and other issues to achieve the effect of avoiding adverse effects, low cost, and avoiding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

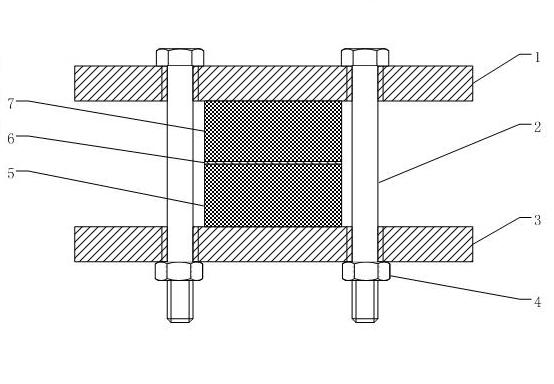

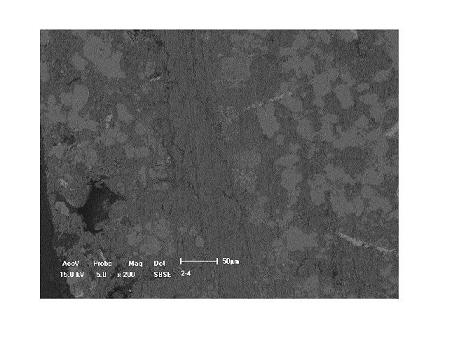

[0027] Embodiment 1: The instant liquid phase diffusion welding connection method of the foamed aluminum material of the present invention is:

[0028] The intermediate layer foil is aluminum alloy Al4004, and its composition by weight percentage is: Al: 86-88.5%, Si: 9.0-10.5%, Mg: 1.0-2.0%, Cu: 0.50-1.3%, Fe: 0.8%, and its thickness is 50 μm. The composition of foamed aluminum is: Al: 87.5%, Si: 12.5%;

[0029] (1) Perform rust and oil removal treatment on the surface of the aluminum foam to be connected, soak it with 10% volume fraction of NaOH solution for 1 minute to remove oxides and impurities, then soak it with 10% volume fraction of HCl solution for 1 minute to neutralize it, and use sandpaper Grind the welding interface of the aluminum foam to be connected and the Al4004 foil (commercial product) of the intermediate layer material, place the treated aluminum foam and Al4004 foil in an ultrasonic instrument to shake for 30 minutes to remove impurities, and finally pl...

Embodiment 2

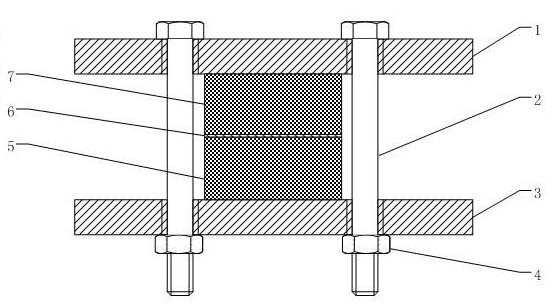

[0034] Embodiment 2: The instant liquid phase diffusion welding connection method of the foamed aluminum material of the present invention is:

[0035] The intermediate layer foil is aluminum alloy Al4004, and its composition by weight percentage is: Al: 86-88.5%, Si: 9.0-10.5%, Mg: 1.0-2.0%, Cu: 0.50-1.3%, Fe: 0.8%, and its thickness is 50 μm. The composition of foamed aluminum is: Al: 87.5%, Si: 12.5%;

[0036] (1) Perform rust and oil removal treatment on the surface of the aluminum foam to be connected, soak it with 10% volume fraction of NaOH solution for 1 minute to remove oxides and impurities, then soak it with 10% volume fraction of HCl solution for 1 minute to neutralize it, and use sandpaper Grind the welding interface of the aluminum foam to be connected and the Al4004 foil (commercial product) of the intermediate layer material, place the treated aluminum foam and Al4004 foil in an ultrasonic instrument to shake for 30 minutes to remove impurities, and finally pl...

Embodiment 3

[0041] Embodiment 3: The instant liquid phase diffusion welding connection method of the foamed aluminum material of the present invention is:

[0042]The intermediate layer foil is aluminum alloy Al4004, and its composition by weight percentage is: Al: 86-88.5%, Si: 9.0-10.5%, Mg: 1.0-2.0%, Cu: 0.50-1.3%, Fe: 0.8%, and its thickness is 50 μm. The composition of foamed aluminum is: Al: 87.5%, Si: 12.5%;

[0043] (1) Perform rust and oil removal treatment on the surface of the aluminum foam to be connected, soak it with 10% volume fraction of NaOH solution for 1 minute to remove oxides and impurities, then soak it with 10% volume fraction of HCl solution for 1 minute to neutralize it, and use sandpaper Grind the welding interface of the aluminum foam to be connected and the Al4004 foil (commercial product) of the intermediate layer material, place the treated aluminum foam and Al4004 foil in an ultrasonic instrument to shake for 30 minutes to remove impurities, and finally pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com