Weather-proof structural steel S355K2W thick plate and production method

A technology of S355K2W and weather-resistant structural steel, which is applied in the direction of improving process efficiency, can solve the problems of increasing production cost and increasing production cycle, and achieve the effects of reducing production energy consumption, simplifying production process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

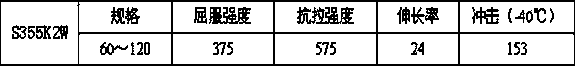

Image

Examples

Embodiment Construction

[0026] The invention adopts the methods of converter smelting, continuous casting and pouring, and rolling in a 3800m wide and thick plate rolling mill to produce S355K2W weather-resistant structural steel plates. Its technological process is: high-quality molten iron, KR molten iron pretreatment, 100 / 120 ton top-bottom combined blowing converter, LF furnace refining, vacuum degassing treatment, billet stack cooling for 24-60 hours, pusher type heating furnace, 3800m rolling mill, ACC laminar cooling, 11-roll hot straightening machine, stack cooling, finishing, external inspection, flaw detection, storage.

[0027] The implementation is as follows:

[0028] Composition design: On the basis of the composition of traditional S355K2W weather-resistant structural steel, the content and proportion of C, Mn, and Nb alloy elements in S355K2W are appropriately adjusted, and the content of P and S is strictly controlled through clean steel smelting, and strict TMCP rolling is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com