Jet-flow-guided laser-spark-electrolysis combined machining device

A combined processing and laser processing technology, applied in the field of structural devices, can solve the problems of no efficient and precise processing method for micro holes with countersunk heads, inability to directly process countersunk heads, and inability to achieve countersunk head accuracy, etc. Low roughness value and low cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

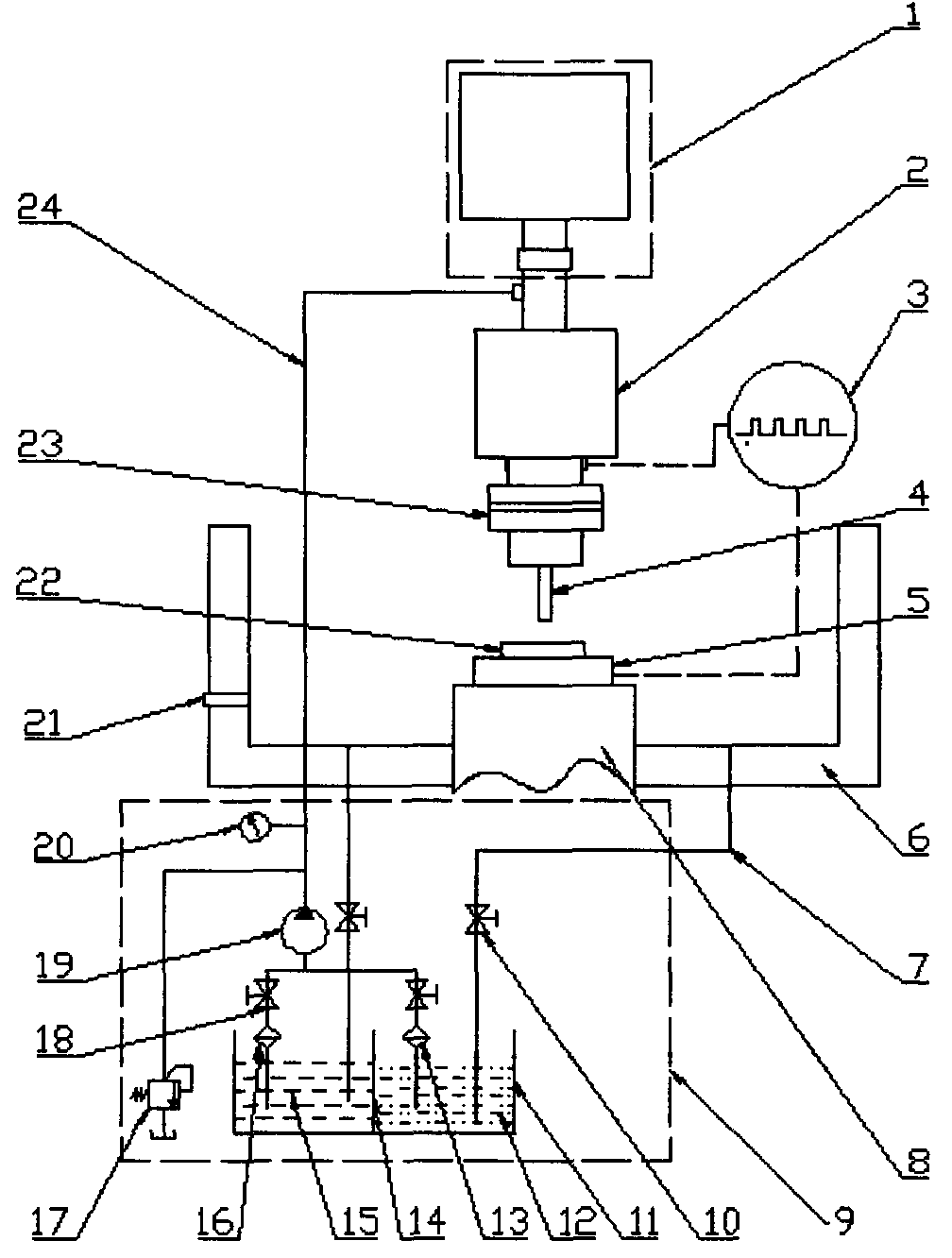

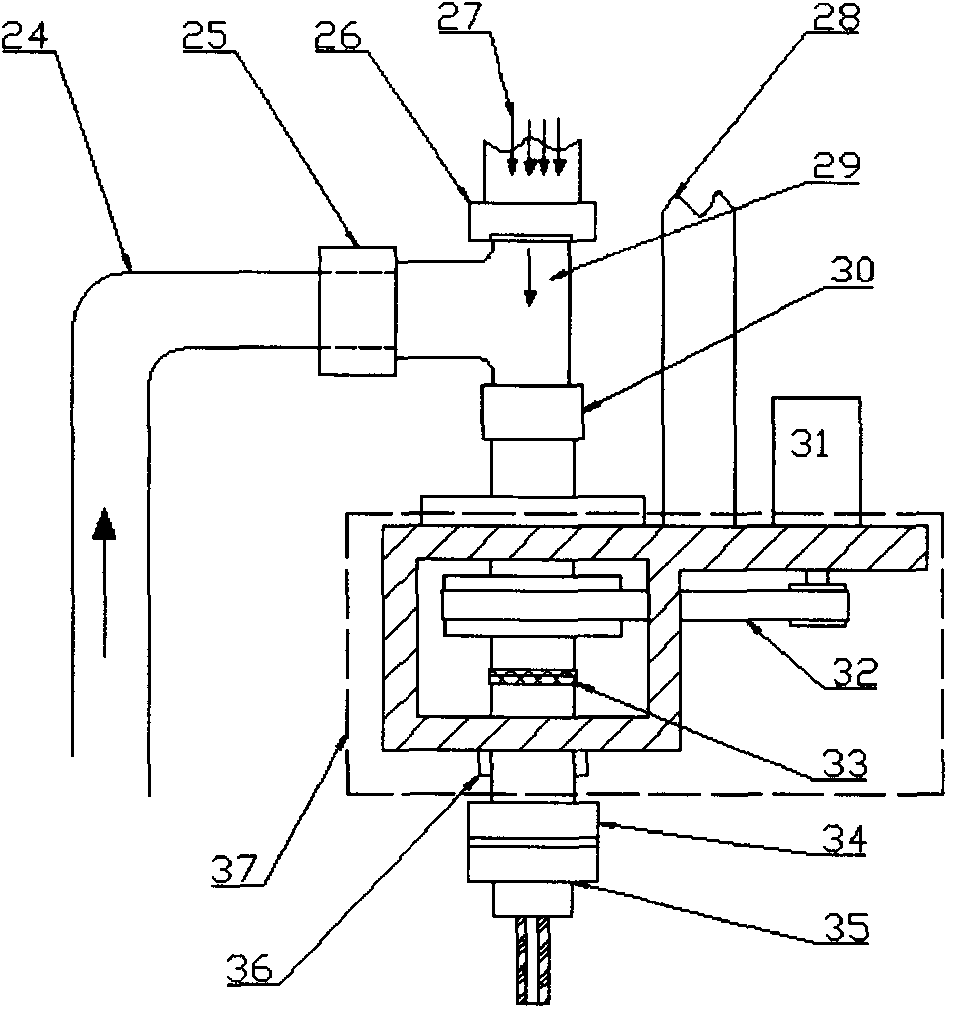

[0024]Implementation example 1: when the device of the present invention is in use, first, according to the actual processing needs, the tubular electrode 4 for electric discharge machining is installed on the electrode chuck 34 through the offline pre-adjustment of the electrode, so as to ensure that the tubular electrode 4 and the electrode chuck 35 have the same High coaxiality; then install the electrode torch 35 on the spindle chuck 34 to ensure that the electrode chuck 35 and the spindle chuck 34 have a very high coaxiality; thereby ensuring that the tubular electrode 4 for EDM and the laser beam 29 has extremely high coaxiality. After the above preparatory work is completed, the working fluid circulation system 9 starts to work, and the deionized water 12 passes through the deionization equipment 13, the switch valve (same as the electrolytic working fluid switch valve 18), the hydraulic pump 19, the hydraulic gauge 20, the liquid inlet pipe 24, The rotary joint 30 fina...

Embodiment example 2

[0025] Implementation example 2: The device of the present invention can adopt two processing combination methods of electric discharge machining and electrolytic machining when machining micro-grooves. Remove the working liquid inlet pipe 24 from the liquid inlet port 25, and then connect with the liquid inlet 21 on the processing tank 6 to quickly provide the working liquid for EDM in the processing tank until the working liquid level is higher than the workpiece 22 After a certain distance from the surface, turn on the liquid return pipe switch 10 for EDM to form a working fluid circulation, turn on the power module and provide electric pulses for EDM for EDM, turn on the motor 31, and drive the tubular electrode 4 to rotate through the timing belt 32 , and use the tubular electrode 4 to perform layer-by-layer electric discharge milling on the fine grooves. Subsequently, the working fluid is replaced, and the electrolytic working fluid 15 passes through the filter device 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com