Corrosion-resistant steel plate for ocean platform and production method of steel plate

The technology of an offshore platform and a production method is applied in the field of steelmaking to achieve the effects of dense organization, good desulfurization effect and suitable smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

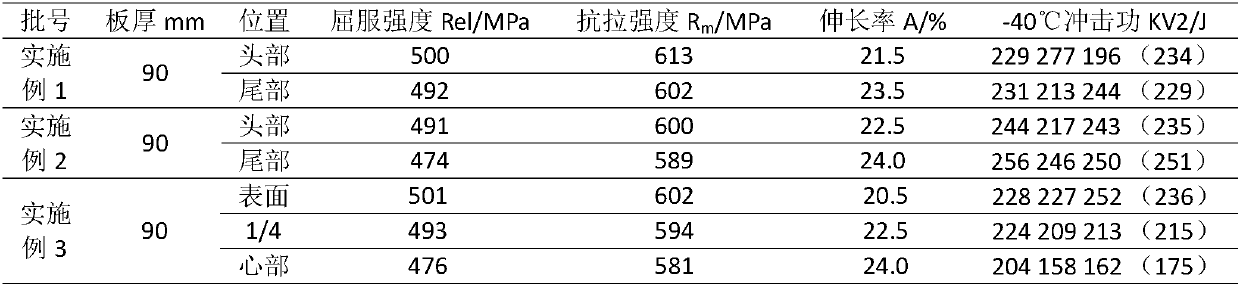

Embodiment 1

[0044] To produce a corrosion-resistant steel plate for marine platforms, the chemical composition and weight percentage are: C: 0.03%, Si: 0.02%, Mn: 1%, P: 0.072%, S: 0.004%, Als: 0.020%, Cr: 0.43%, Mo: 0.50%, Zr: 0.09%, Nb: 0.049%, Ni: 0.8%, Ce: 0.03%, Cu: 0.75%, Ca: 0.0028%, the others are Fe and inevitable impurities.

Embodiment 2

[0046] To produce a corrosion-resistant steel plate for offshore platforms. Its chemical composition and weight percentage are: C: 0.05%, Si: 0.08%, Mn: 1.03%, P: 0.075%, S: 0.005%, Als: 0.040%, Cr: 0.49%, Mo: 0.52%, Zr: 0.10%, Nb: 0.053%, Ni: 0.82%, Ce: 0.04%, Cu: 0.79%, Ca: 0.003%, the others are Fe and unavoidable impurities.

Embodiment 3

[0048] To produce a corrosion-resistant steel plate for offshore platforms. Its chemical composition and weight percentage are: C: 0.04%, Si: 0.07%, Mn: 1.01%, P: 0.073%, S: 0.002%, Als: 0.034%, Cr: 0.48%, Mo: 0.49%, Zr: 0.082%, Nb: 0.049%, Ni: 0.81%, Ce: 0.032%, Cu: 0.74, Ca: 0.0027%, the others are Fe and unavoidable impurities.

[0049] The above-mentioned embodiment 1, embodiment 2 and embodiment 3 are all realized by the following steps: 1) KR molten iron pretreatment: when the slag before and after slag is scraped, the thickness of the slag layer on the liquid surface is ≤20mm, and the molten iron passes through KR. After stirring and desulfurization, the S content of molten iron is ≤0.005%, the desulfurization cycle is 17-20min, and the temperature drop of desulfurization is ≤20℃;

[0050] 2) Converter smelting: when entering the furnace, the molten iron S content is less than or equal to 0.005%, P content is less than or equal to 0.08%, the molten iron temperature is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com