Combined laser-electric spark-electrolysis machining method and device for micro holes with countersunk heads

A technology of combined processing and combined devices, which is applied in the field of laser-electric spark-electrolysis combined processing, the processing device dedicated to this method, can solve the problems of high-efficiency and precision processing methods for micro-holes with countersunk heads, which are not given, and achieve high speed Fast, small heat-affected zone, high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025]Implementation case 1: This case is a laser-EDM-electrolytic machining method for micro-holes with countersunk heads. First, the laser beam is used to pre-process the through-holes of the countersunk micro-holes on the workpiece, and then the tubular copper electrodes are used to countersunk the micro-holes. Carry out EDM to basically achieve the required shape accuracy of the countersunk head, and finally use the high-speed jet electrolyte beam coaxial with the EDM electrode to electrolytically process the entire micro-hole with the countersunk head to remove the remaining parts after the first two processes The recasting layer realizes no residual stress and high-efficiency machining of countersunk micro-holes.

[0026] The electric discharge machining fluid is deionized water or distilled water, and the electrolyte is low-concentration strong acid and strong alkali salt.

Embodiment example 2

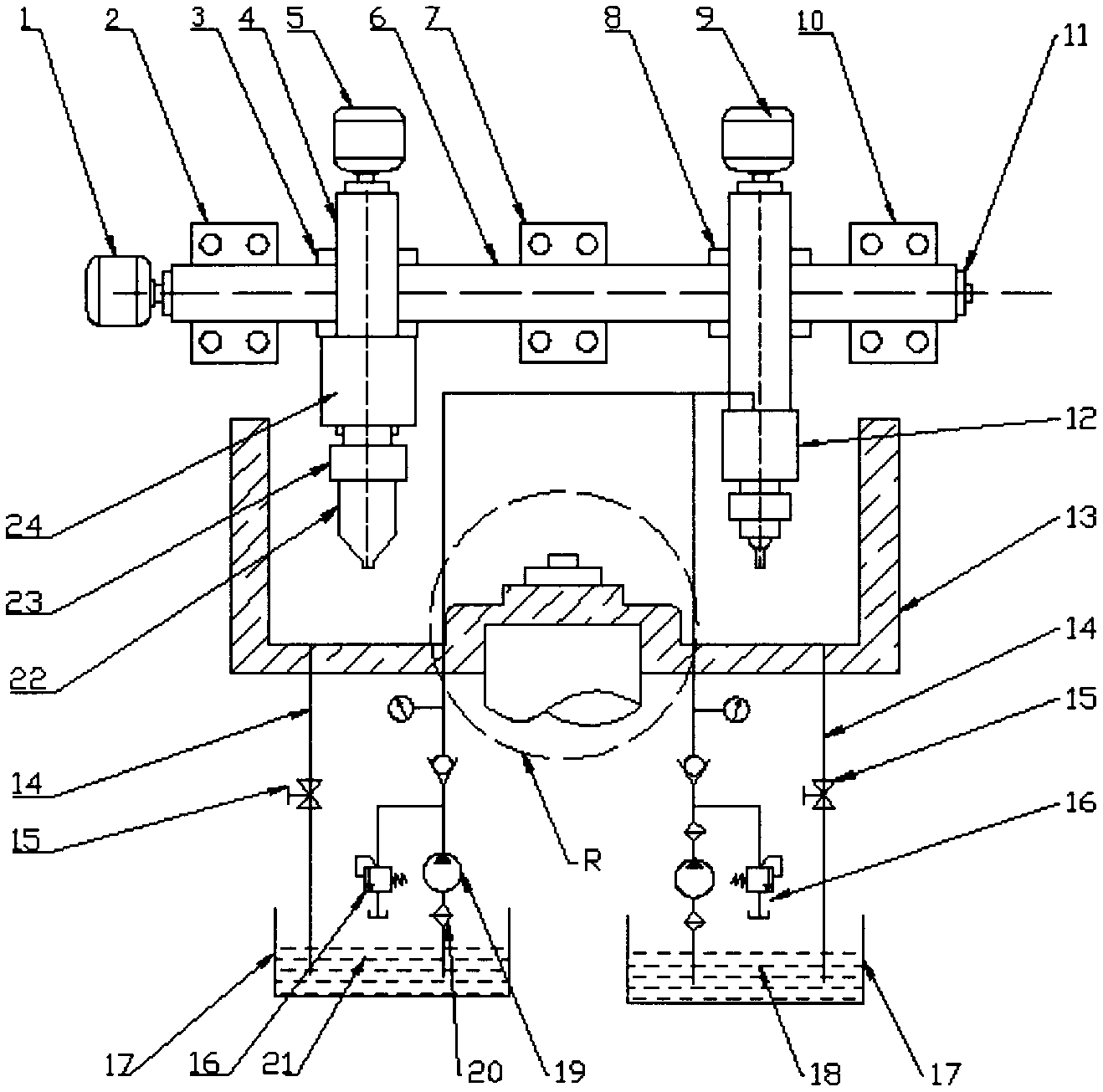

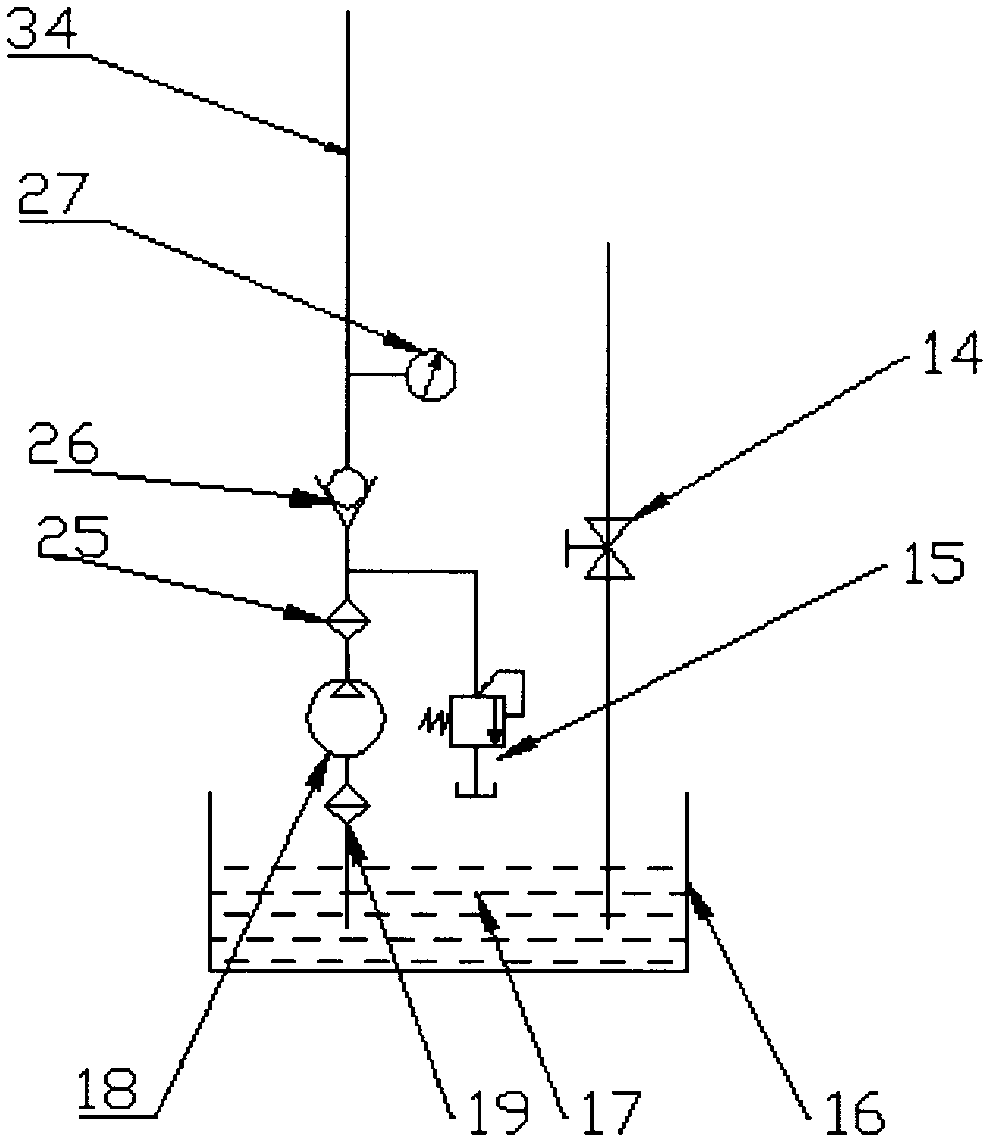

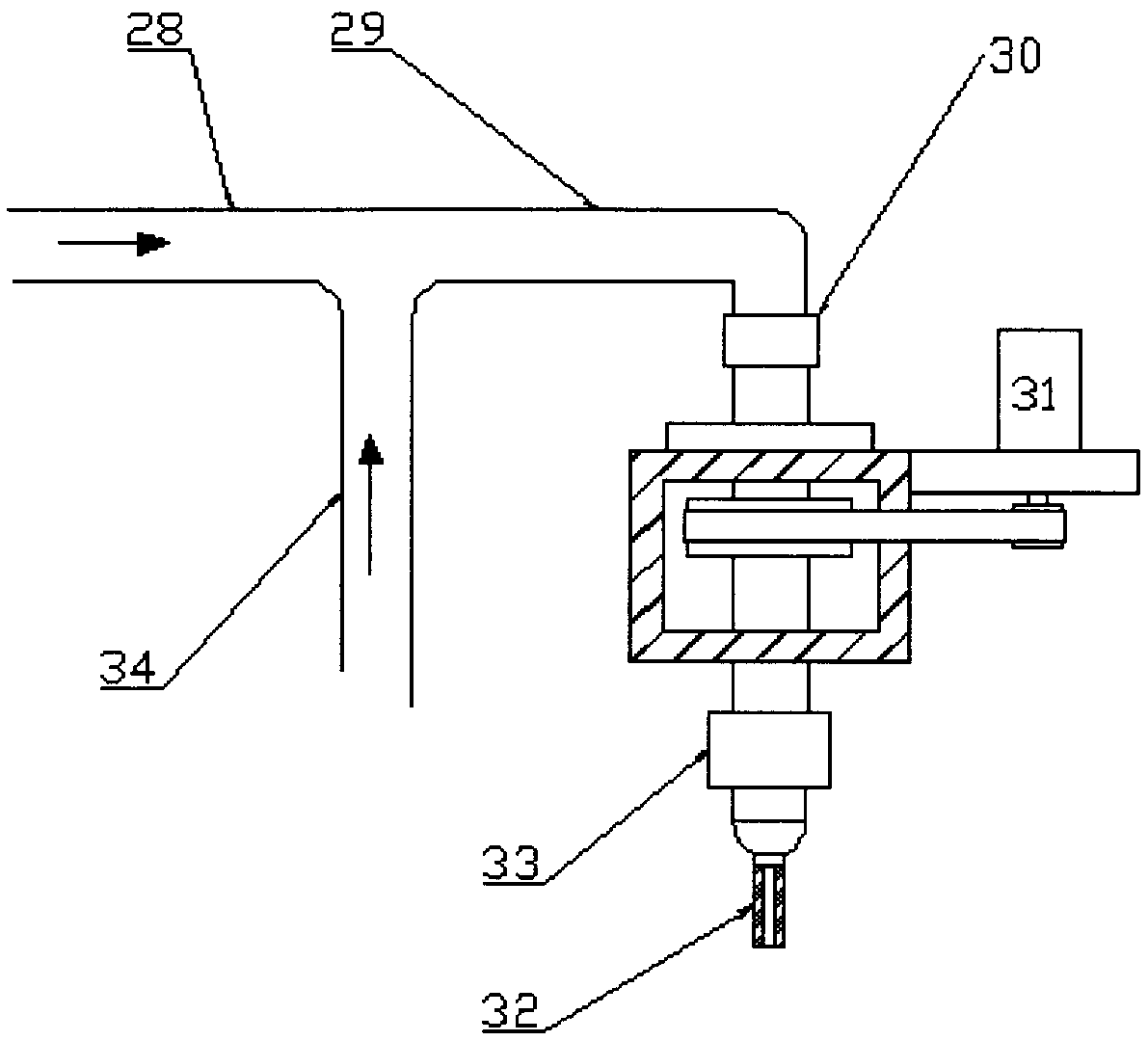

[0027] Implementation case 2: This implementation case is a micro-hole laser-EDM-electrolytic machining device with a conical countersunk head and an axisymmetric countersunk head, including a laser generating device, a combined device for EDM and electrolytic processing, a processing method conversion device, and a working fluid Circulation system, power supply and control system. Among them, the laser generating device, EDM and ECM combination device are installed in parallel on the processing mode conversion device, and move through the movement command issued by the control system; the working fluid circulation system provides processing fluid for EDM and ECM respectively.

[0028] The processing mode conversion device includes: 1. motor, 2. support for fixing, 6. sliding guide rail, 7. support for fixing, 10. support for fixing, 11. precision ball screw. Among them, the motor 1 provides the driving force for the movement of the laser generating device, the electric discha...

Embodiment 3

[0033] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, but the processing object is a micro hole with a non-axisymmetric countersunk such as a dustpan-shaped countersunk. In this embodiment, the electrode for electrical discharge machining does not rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com