A kind of internal spinning forming method

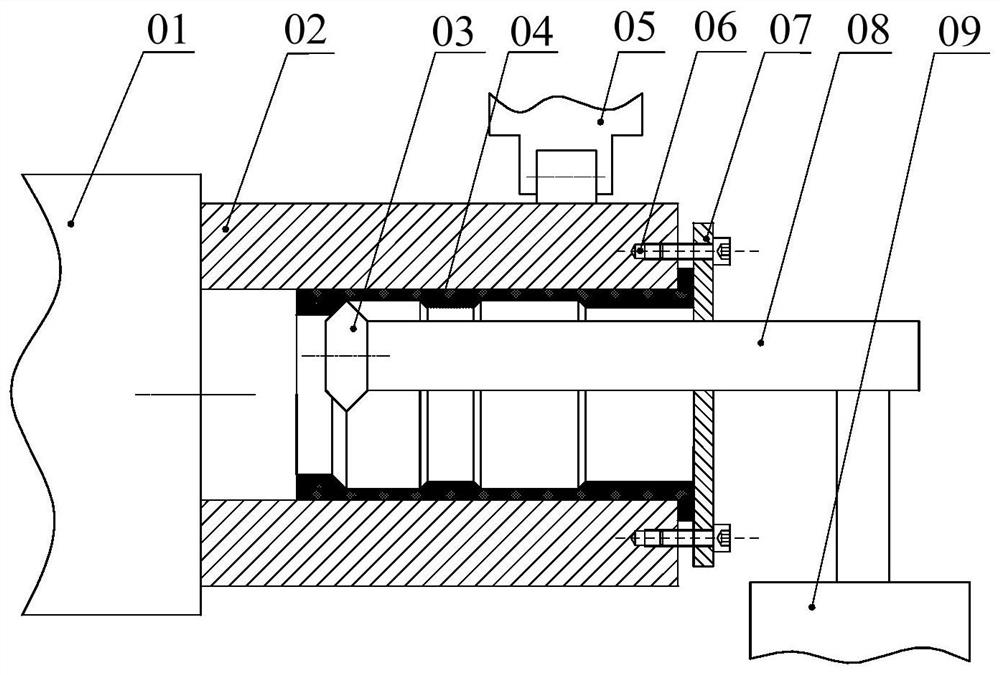

An internal spinning and wheel spinning technology, applied in the field of spinning forming, can solve the problems of excessively long spinning wheel arms, high manufacturing difficulty and high production cost, and achieves optimized straightness accuracy and roundness accuracy, optimized diameter accuracy and wall thickness. The effect of thick precision, reducing manufacturing difficulty and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

[0073] Processing cylinder products, the manufacturing length is 1300mm, the thickness is 10mm, the outer diameter is 550mm, the outer diameter of the process ring is 562mm, and the material is 5A06 aluminum alloy.

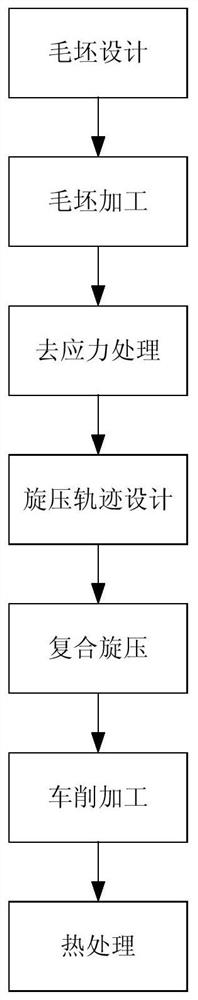

[0074] Processing technology such as figure 2 shown in the following steps:

[0075] 1. Rough design

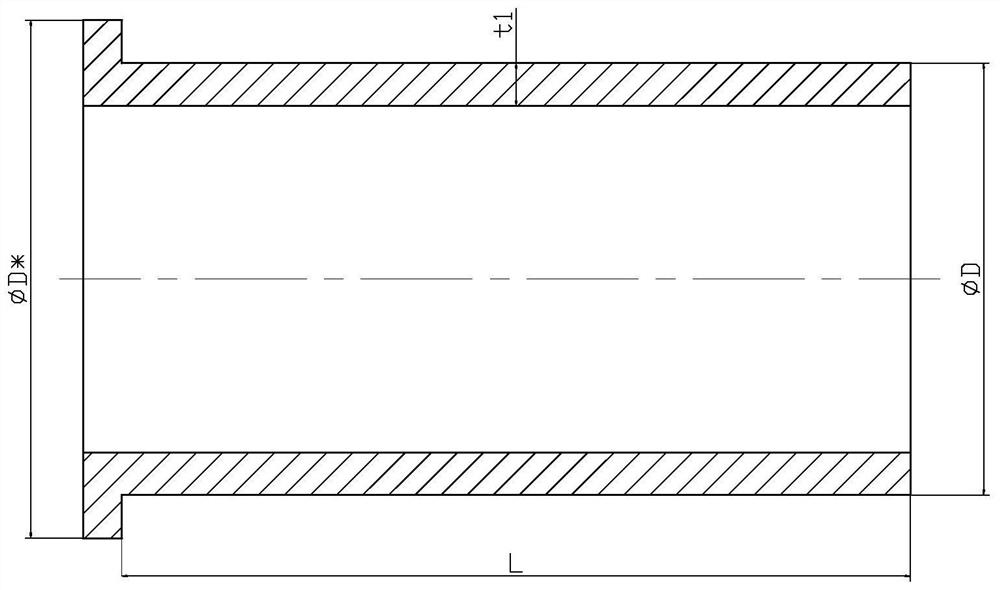

[0076] The spinning blank 5 is designed as image 3 In the straight cylindrical structure with a protruding process ring at one end shown, its wall thickness t1 is determined according to the calculation of the thinning rate of the cylinder, and the length of the blank 5 is obtained from the comprehensive calculation of the product according to the principle of constant volume and considering the reserved process margin. The outer diameter φD is determined according to the law of internal rotation pressure expansion diameter. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com