Simple mold for molding channel cover

A mold and simple technology, which is applied in the field of simple molds for forming arc groove cover, can solve the problems of time-consuming and difficult to ensure quality, and achieve the effects of convenient use, improved machining accuracy, and high forming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

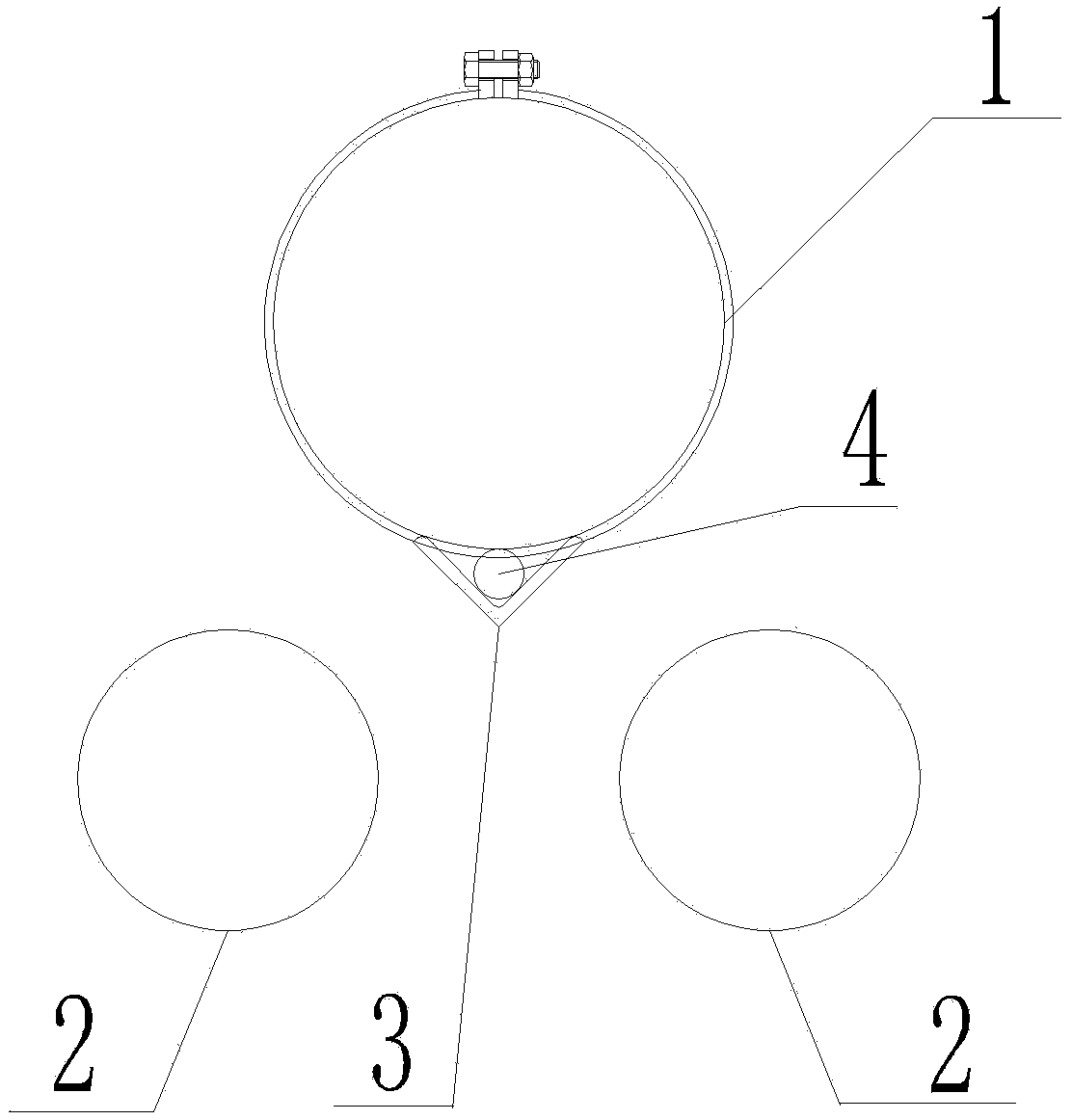

[0011] Such as figure 1 As shown, the simple mold for forming the groove cover includes an upper roller shaft 1 and a lower roller shaft 2. The upper roller shaft 1 is provided with a V-shaped arc bar mold 3, and the V-shaped opening of the arc bar mold 3 is provided with a reinforcing roller 4. The upper roller The distance between the shaft 1 and the lower roller shaft 2 is adjusted by the plate rolling machine. There is one upper roller shaft 1 and two lower roller shafts 2. The width of the arc bar die 3 is smaller than that of the upper roller shaft 1 and fastened to the Vertically below the upper roller shaft 1.

[0012] Working principle: When using, put the workpiece to be processed between the upper roller 1 and the lower roller 2, so that the arc pressing bar mold 3 is aligned with the arc center line of the workpiece to be processed, and adjust the upper roller according to the arc to be processed 1. The distance between the lower rollers 2 can start to process the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com