Polycrystalline diamond cubic boron nitride composite sheet and preparation method thereof

A polycrystalline diamond, cubic boron nitride technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of easy cracking, poor impact toughness, etc., to achieve good wear resistance and toughness, improved impact toughness, The effect of high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

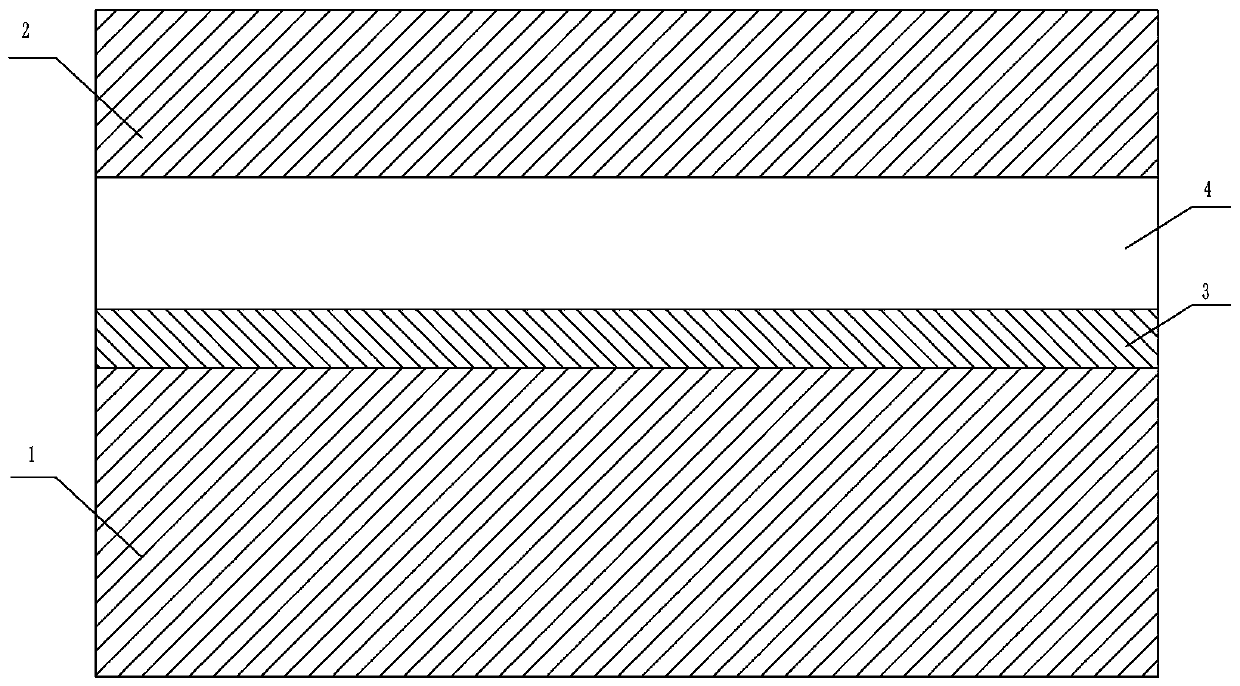

[0026] This embodiment provides a polycrystalline diamond cubic boron nitride composite sheet, such as figure 1 As shown, it includes cemented carbide substrate 1, polycrystalline diamond composite layer 3, polycrystalline cubic boron nitride composite layer 4 and cemented carbide protective layer 2 arranged in sequence from bottom to top. Composite to form a superhard composite material.

[0027] Wherein, in this embodiment, the cemented carbide substrate is a tungsten-cobalt alloy with a cobalt content of 10%. The thickness of the hard alloy substrate is 6mm, the thickness of the hard alloy protective layer is 3mm, the thickness of the polycrystalline diamond composite layer is 0.5mm, and the thickness of the polycrystalline cubic boron nitride composite layer is 1mm .

[0028] Specifically, the polycrystalline diamond composite layer is composed of diamond micropowder and nano-metal bonding agent, and is connected to the polycrystalline cubic boron nitride composite layer...

Embodiment 2

[0040] This embodiment provides a polycrystalline diamond cubic boron nitride composite sheet, such as figure 1 As shown, it includes cemented carbide substrate 1, polycrystalline diamond composite layer 3, polycrystalline cubic boron nitride composite layer 4 and cemented carbide protective layer 2 arranged in sequence from bottom to top. Composite to form a superhard composite material.

[0041] Wherein, in this embodiment, the cemented carbide substrate is a tungsten-cobalt alloy with a cobalt content of 3%. The thickness of the cemented carbide substrate is 12mm, the thickness of the cemented carbide protective layer is 5mm, the thickness of the polycrystalline diamond composite layer is 1mm, and the thickness of the polycrystalline cubic boron nitride composite layer is 2mm.

[0042] Specifically, the polycrystalline diamond composite layer is composed of diamond micropowder and nano-metal bonding agent, and is connected to the polycrystalline cubic boron nitride composi...

Embodiment 3

[0054] This embodiment provides a polycrystalline diamond cubic boron nitride composite sheet, such as figure 1 As shown, it includes cemented carbide substrate 1, polycrystalline diamond composite layer 3, polycrystalline cubic boron nitride composite layer 4 and cemented carbide protective layer 2 arranged in sequence from bottom to top. Composite to form a superhard composite material.

[0055] Wherein, in this embodiment, the cemented carbide substrate is a tungsten-cobalt alloy with a cobalt content of 5%. The thickness of the hard alloy substrate is 8mm, the thickness of the hard alloy protective layer is 3.5mm, the thickness of the polycrystalline diamond composite layer is 0.6mm, and the thickness of the polycrystalline cubic boron nitride composite layer is 1.5mm.

[0056] Specifically, the polycrystalline diamond composite layer is composed of diamond micropowder and nano-metal bonding agent, and is connected to the polycrystalline cubic boron nitride composite lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com