Color matching injection molding device

An injection molding and injection molding machine technology, applied in the field of color matching injection molding devices, can solve the problems of uneven thickness of color blocks, easy jamming, unqualified production and molding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

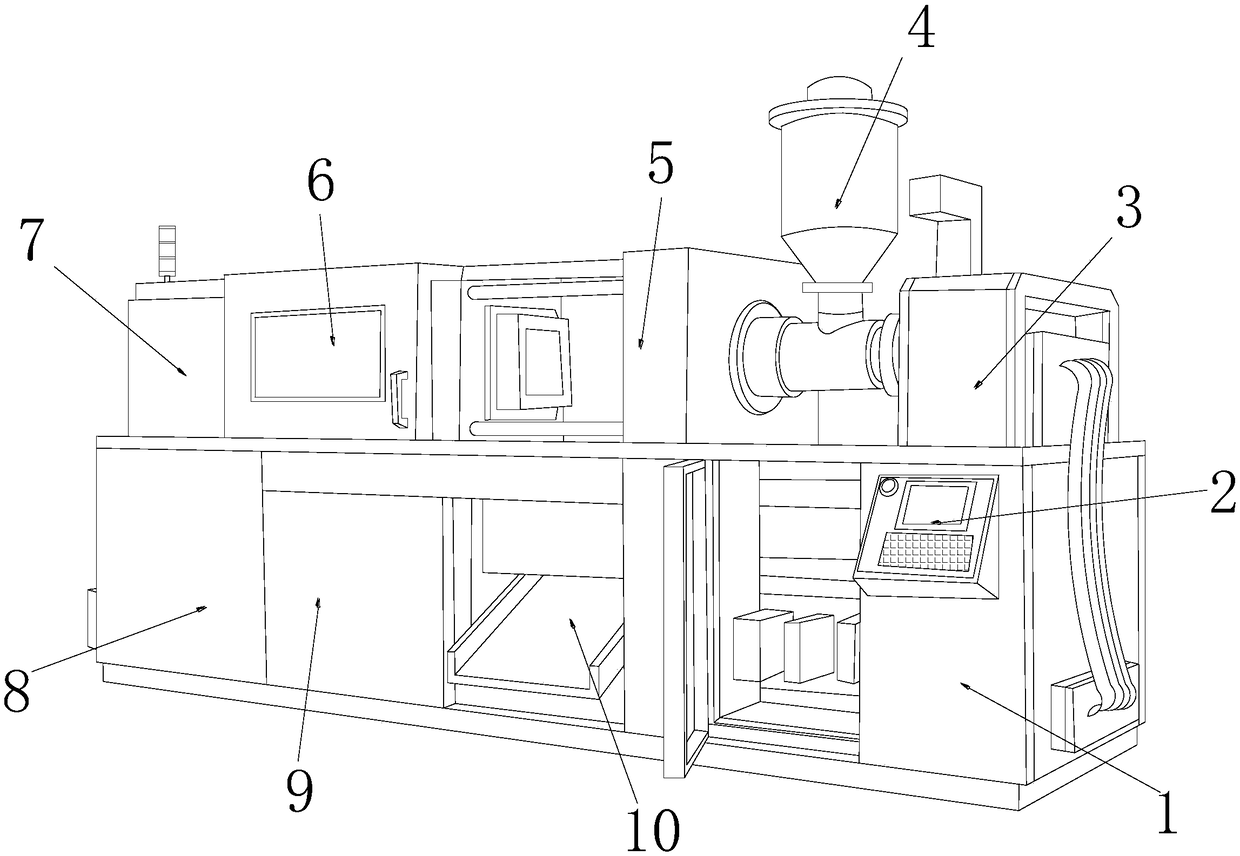

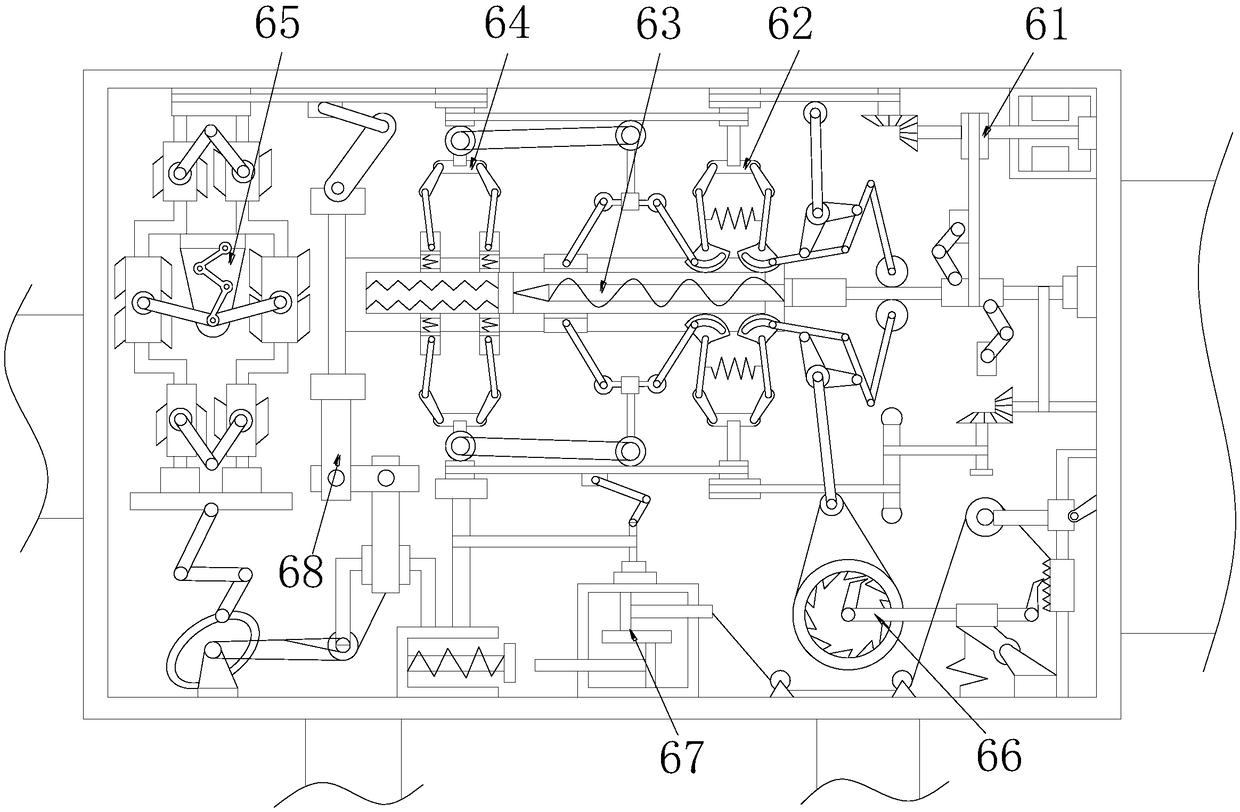

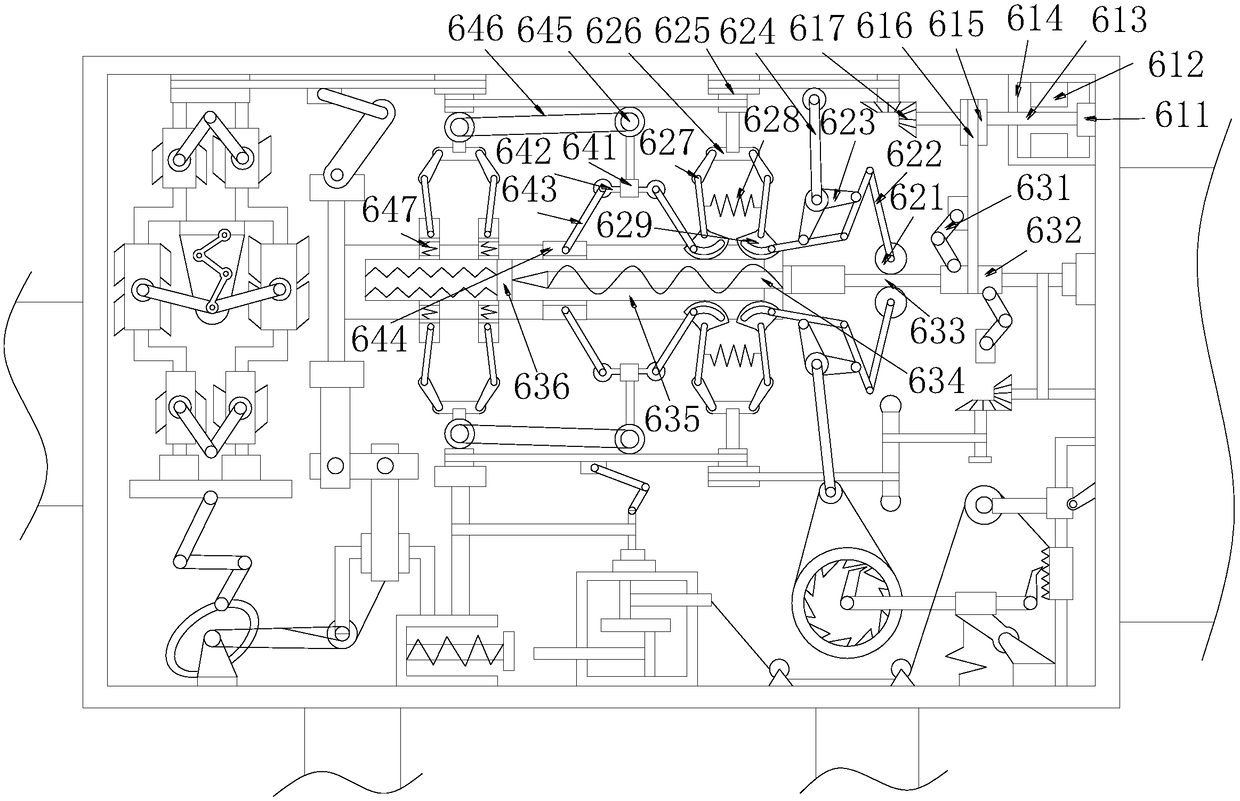

[0025] see Figure 1-Figure 5, the present invention provides a color matching injection molding device, the structure of which includes: distribution box 1, industrial control board 2, screw feeding box 3, injection molding tank 4, injection molding machine 5, roller brushing machine 6, output square groove 7, Locker 8, pressure transmitter 9, slag discharge chute 10, the output square groove 7 is welded on the left side of the roller brush separator 6 and communicates with each other, and the injection molding machine 5 is separated from the roller through the roller The brush machine 6 is mechanically connected, the injection molding tank 4 is inserted in the upper left corner of the screw feeding box 3 and communicates with each other, the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com