A kind of chromatographic cake filler and its application

A chromatographic cake and seed technology, which is applied in the field of high-performance liquid chromatography packing, can solve problems such as increased column pressure, high cost, and complex samples, and achieve the effects of rapid and low-pressure separation, high bonding density, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example is the synthesis of sub-2 micron glycidyl methacrylate microspheres. The specific method is as follows:

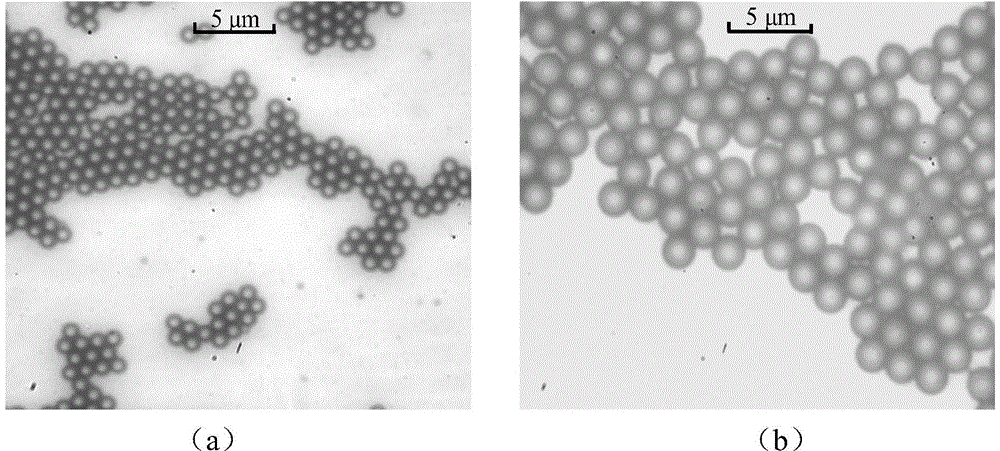

[0035] Put 0.5g of initiator benzoyl peroxide and 1.0g of stabilizer polyvinylpyrrolidone in a 250mL reaction flask, add 80mL of absolute ethanol and 15mL of deionized water into the reaction flask, and then ultrasonically dissolve the initiator and stabilizer After completely dissolving, add 15mL of styrene, stir evenly and heat at 70°C for 24h at a stirring speed of 120r / min. The particle size of the finally obtained polystyrene seeds was 0.5 μm, the dispersion coefficient was 0.018, and the figure 1 (a) The 10,000-fold magnification image of styrene seeds under a microscope.

[0036] Without separating the styrene seeds obtained above, directly pipette 12 mL of the styrene seed solution into a 500 mL three-necked flask, and add 40 mL of 0.2% SDS at the same time.

[0037] In addition, 5.0 mL of dibutyl phthalate was mixed with 100 mL of 0.2% SDS, ...

Embodiment 2

[0040] This embodiment is the modification of glycidyl methacrylate microspheres, and the specific method is as follows:

[0041] Weigh 10.0 g of glycidyl methacrylate microspheres into a 250 mL flask, then add 1.0 M dilute sulfuric acid (dilute hydrochloric acid can also be used) 120 mL, heat in a water bath at 50 ° C, and stir for 6 hours to prepare hydrolyzed microspheres; Adjust the pH to 10 with 0.5M sodium hydroxide solution, then add 5.0mL of chloroacetic acid, and react at a constant temperature of 60°C for 12h to prepare the modified weak cation exchange packing. The product was repeatedly washed with distilled water and acetone for 2 to 3 times, and then dried in vacuum at 60°C for 4 hours.

[0042] Infrared spectroscopy confirmed that the strong absorption peak of the filler at 1645 cm- is the characteristic absorption peak of -COOH, and the content of carboxyl groups on the surface of the resin was determined to be 0.75 mmol / g.

Embodiment 3

[0044] This embodiment is the application of the sub-2 μm weak cation exchange filler prepared in Example 2, and the specific method is as follows:

[0045] Weigh 5.0g sub-2μm weak cation exchange filler into a 100mL beaker, add 50mL methanol for ultrasonic dispersion, and then use a column packing machine to pack it into a chromatographic cake with a diameter of 5 cm and a thickness of 2 cm under a pressure of 2.5Mpa. After loading, connect the chromatographic cake to a high-performance liquid chromatograph, and wash it with distilled water for 30 minutes at a flow rate of 1.0 mL / min.

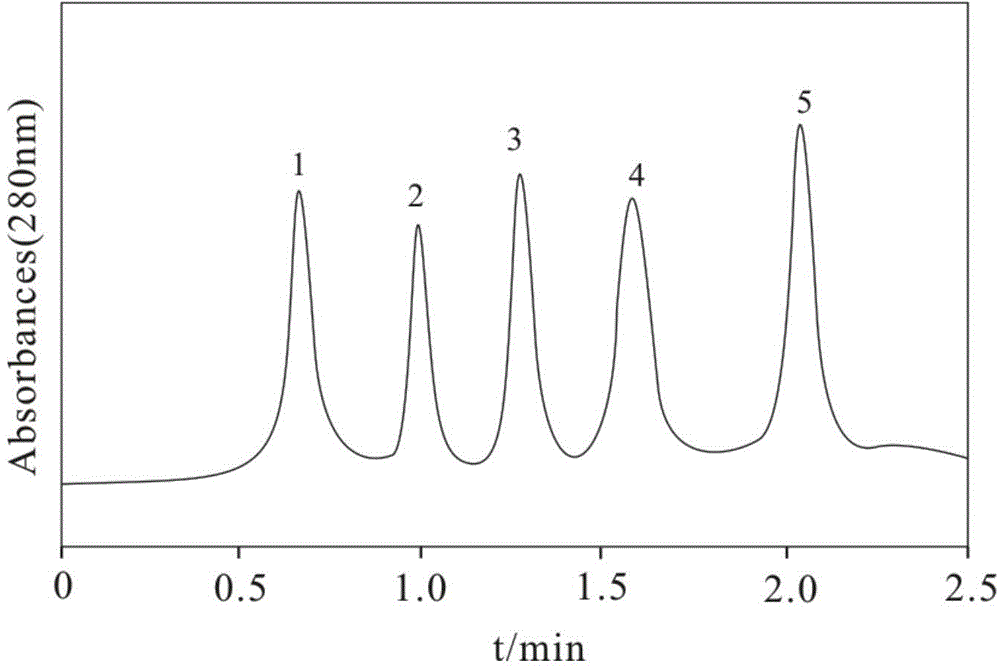

[0046] Equilibrium chromatographic system using ion exchange chromatography mobile phase, mobile phase composition: A liquid, 20mmol / LKH 2 PO 4 , pH=6.5; B solution, 20mmol / L KH 2 PO 4 +1.0mol / L NaCl, pH=6.5; the flow rate is 2.0mL / min; ), 4, 10 μL each of α-chymotrypsin (α-Chy) and lysozyme (Lys) were mixed and injected into the chromatographic system for experiments. The chromatographic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com