Electrochemical modification method for silicon face biology performance

A biological and silicon surface technology, applied in chemical instruments and methods, crystal growth, anodic oxidation, etc., can solve the problems of easy peeling off of the coating surface and poor biocompatibility of the coating, so as to achieve the goal of not falling off easily and improving biocompatibility sex, bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Electrolyte solution preparation: Accurately weigh 10 grams of analytically pure sodium phosphate, dissolve it in 90 grams of deionized water to obtain alkaline electrolyte solution A, and the concentration of alkaline electrolyte solution A is 10 wt%.

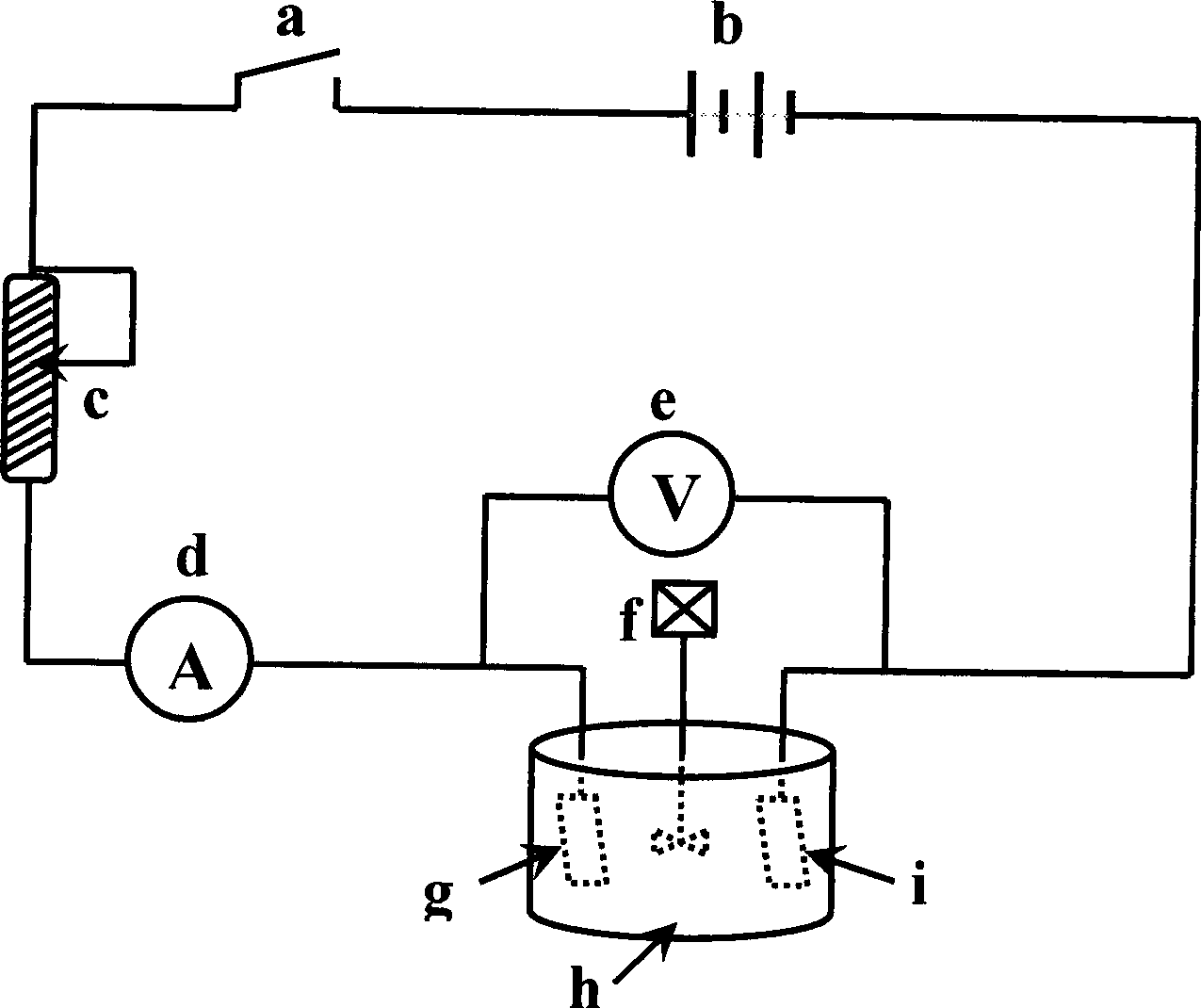

[0047] 2) Anodic oxidation of silicon: Anodic oxidation of silicon: in the attached figure 1 In the anodic oxidation circuit shown, a double-electrode electrolytic system is formed with a single crystal silicon wafer with a clean surface as the anode g and graphite as the cathode i. The alkaline electrolyte solution A prepared above is used as the anodic oxidation medium h, and constant voltage and constant current electrophoresis is used. Instrument b is a DC power supply for anodizing silicon wafers, switch a controls the opening and closing of the circuit, sliding rheostat c precisely adjusts the current in the circuit, digital DC ammeter d indicates the current value flowing through the circuit, and digital DC vol...

Embodiment 2

[0051] 1) Electrolyte solution preparation: accurately weigh 600 grams of analytically pure sodium hydroxide, and dissolve it in 400 grams of distilled water to obtain alkaline electrolyte solution A, the concentration of alkaline electrolyte solution A being 60 wt%.

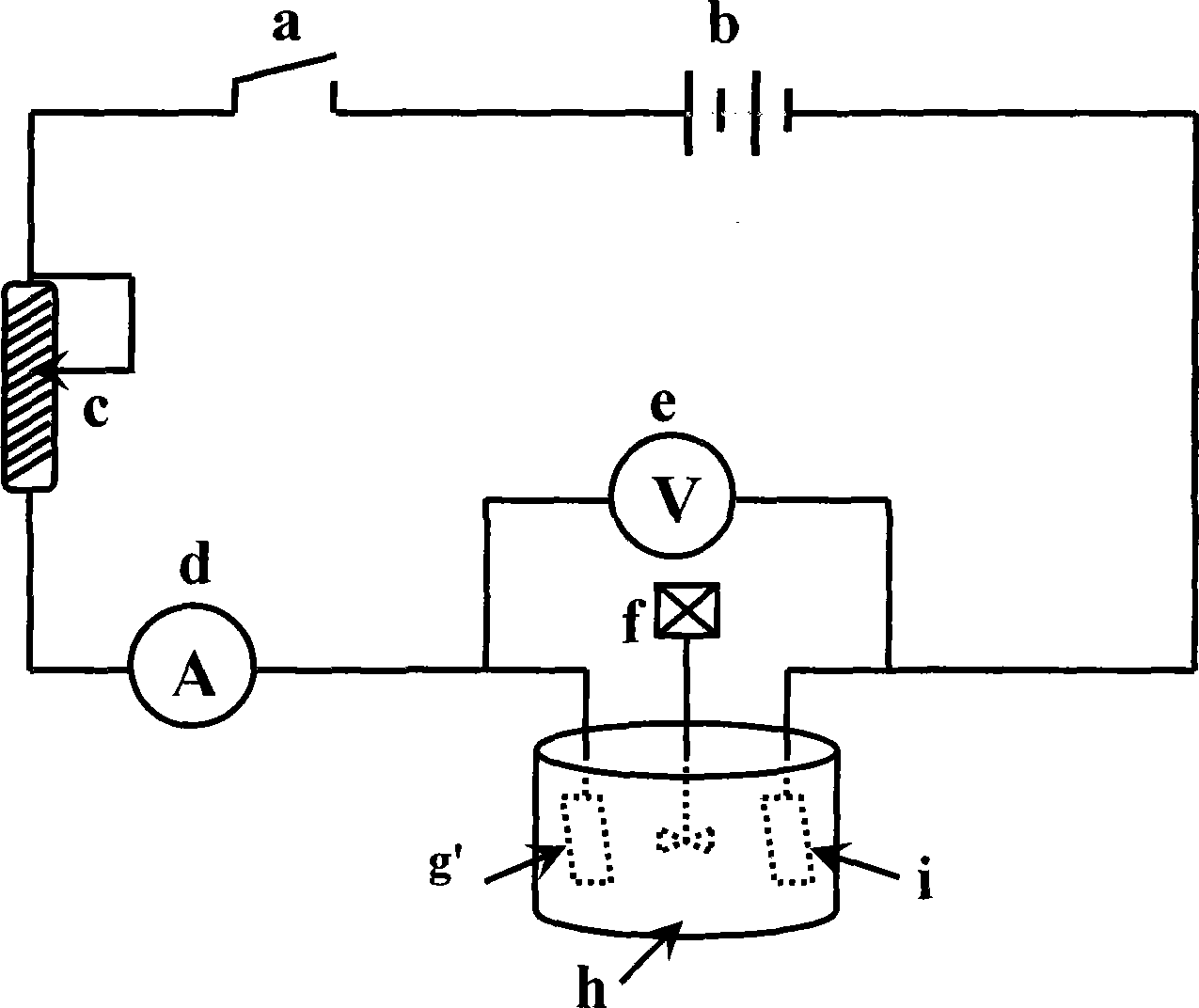

[0052] 2) Anodization of silicon: in the attached image 3 In the anodic oxidation circuit shown, a double-electrode electrolytic system is formed by using a polycrystalline silicon wafer with a clean surface as the anode g′ and graphite as the cathode i, and using the alkaline electrolyte solution A prepared above as the anodic oxidation medium h, using a constant voltage and constant current electrophoresis apparatus b is the direct current power supply to anodize the silicon chip, the switch a controls the opening and closing of the circuit, the sliding rheostat c precisely adjusts the current in the circuit, the digital direct current meter d indicates the current value flowing through the circuit, and the di...

Embodiment 3

[0056] 1) Preparation of electrolyte solution: preparation of electrolyte solution: accurately measure 139 grams of analytically pure hydrogen peroxide solution, which has a mass content of 36 wt%, and dissolve it in 861 grams of pure water to obtain weakly acidic electrolyte solution B and weakly acidic electrolyte solution B. The concentration is 5 wt%.

[0057] 2) Anodization of silicon: in the attached Figure 4 In the shown anodic oxidation circuit, a double-electrode electrolysis system is formed by using a single crystal silicon wafer with a clean surface as the anode g and a platinum wafer as the cathode i'. The constant current electrophoresis instrument b is a DC power supply for anodizing silicon wafers, the switch a controls the opening and closing of the circuit, the sliding rheostat c precisely adjusts the current in the circuit, and the digital DC ammeter d indicates the value of the current flowing through the circuit. The DC voltmeter e indicates the cell vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com