Burner fire cover used for gas cooking appliance and burner with fire cover

A gas cooker and burner technology, which is applied in the direction of gas fuel burners, burners, and combustion methods, can solve the problems of increased fire cover weight, waste of materials, manufacturing costs, and poor gas adaptability, so as to improve gas adaptability and improve adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

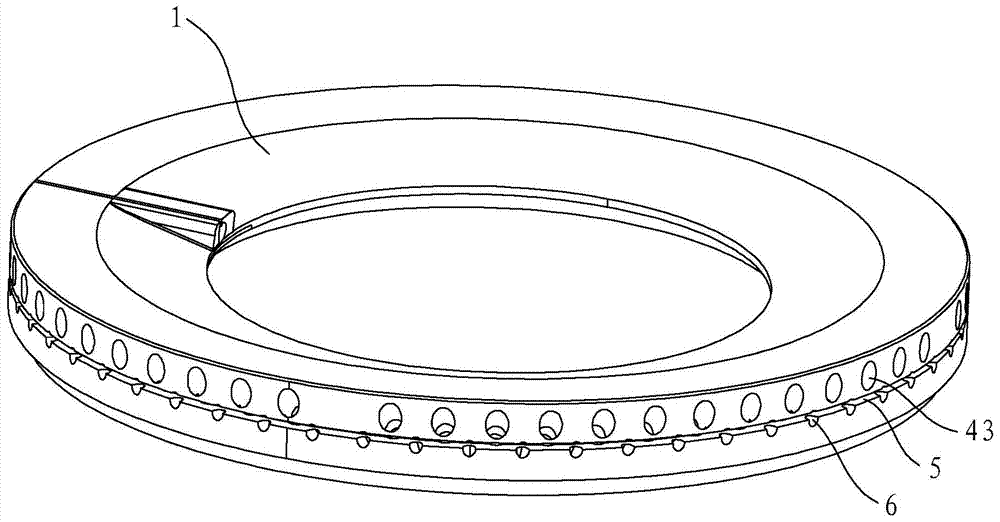

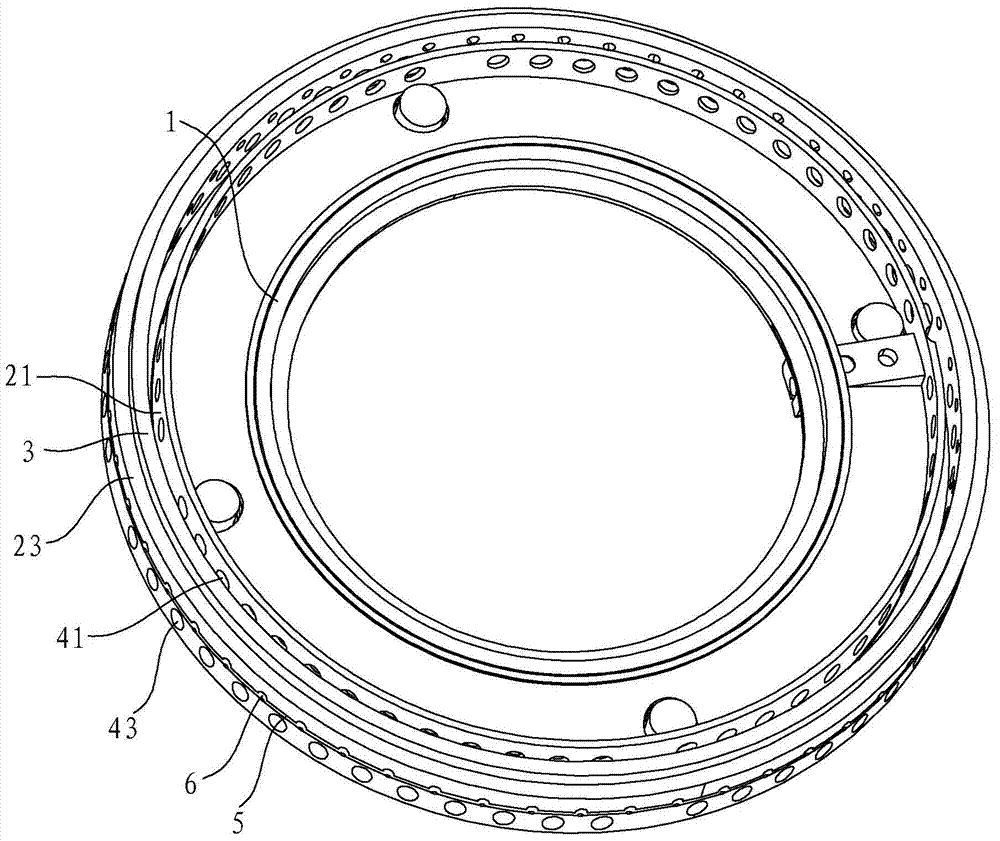

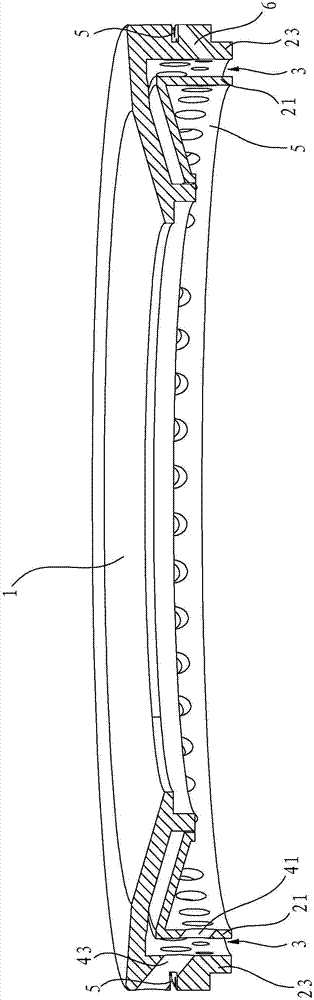

[0025] Such as Figure 1 to Figure 3 As shown, the burner fire cover for a gas cooker in this embodiment includes a fire cover body 1 , and the fire cover body 1 has double-layer annular side walls, specifically an inner annular side wall 21 and an outer annular side wall 23 . There is a gap between the inner annular side wall 21 and the outer annular side wall 23 to form a buffer layer 3, and the inner layer of fire holes 41 are distributed along the circumferential direction on the inner annular side wall 21, and the outer annular side wall 23 There are outer layer fire holes 43 distributed along the circumferential direction, the outer layer fire holes 43 correspond to the inner layer fire holes 41 one by one and the corresponding fire holes are arranged coaxially, thereby reducing the gas outlet resistance of the gas. And, the aperture of outer layer fire hole 43 is greater than the aperture of corresponding inner layer fire hole 41, thereby makes inner layer fire hole int...

Embodiment 2

[0029] Such as Figure 5 with Image 6 As shown, the fire cover body 1 of the burner fire cover in this embodiment has three layers of annular side walls, specifically the inner layer annular side wall 21, the middle layer annular side wall 22 and the outer layer annular side wall 23, the inner layer annular side wall There are gaps between the wall 21 and the middle annular side wall 22 and between the middle annular side wall 22 and the outer annular side wall 23 to form the buffer layer 3 . On the inner annular side wall 21, there are inner layer fire holes 41 distributed along the circumferential direction, on the middle layer annular side wall 22, there are intermediate layer fire holes 42 distributed along the circumferential direction, on the outer annular side wall 23 along the circumferential direction Outer layer fire holes 43 are distributed. The inner layer fire hole 41, the middle layer fire hole 42 and the outer layer fire hole 43 correspond one by one and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com