Efficient electrolyzer and its water-burning unit

A technology for electrolyzers and water burners, used in burners, electrolysis processes, electrolysis components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

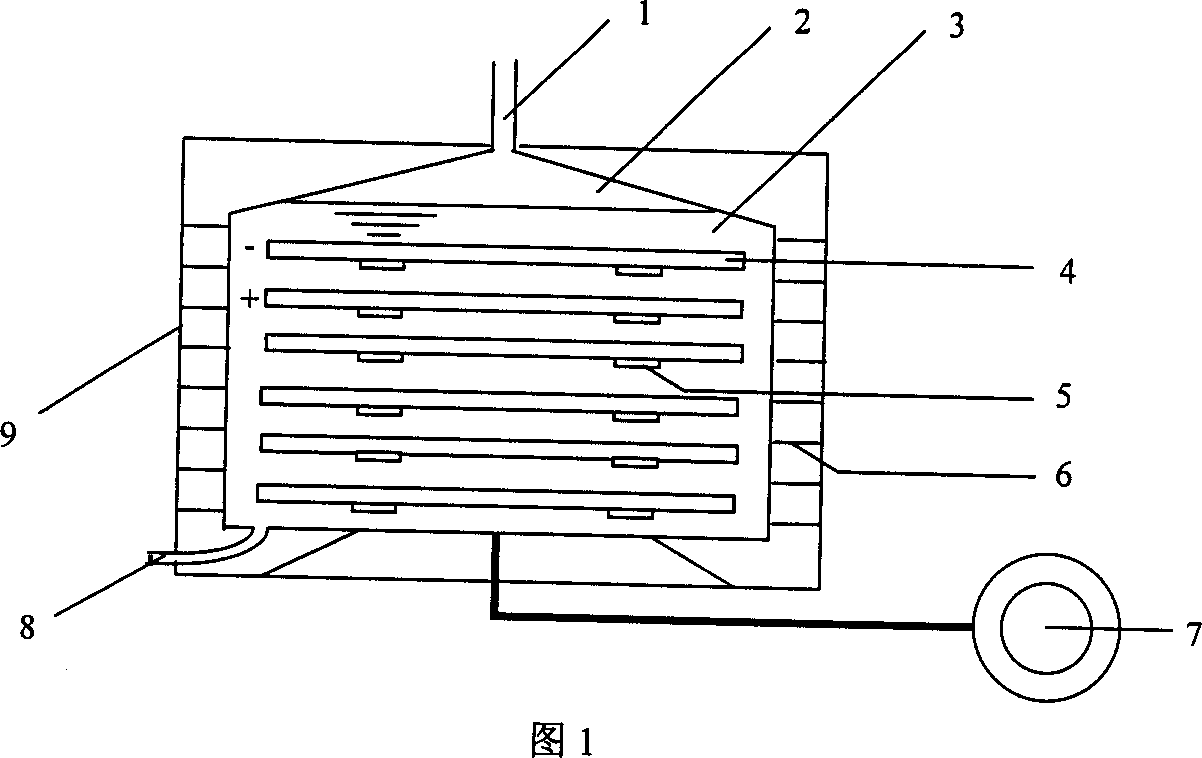

[0033] Embodiment 1: Taking a water burner with a gas production rate of 1500 liters / hour as an example, the working process and performance of the inventive device are described. Add potassium hydroxide of 30% by weight to 5 liters of water or distilled water, stir and dissolve fully, inject it into the inverted Y-shaped water injection port of the water burner device; after sealing the water injection port, turn on the 220V power supply, and gradually turn on As large as 10A-15A (ampere), water is electrolyzed in the electrolyzer to produce hydrogen and oxygen, and the barometer on the instrument panel of the water burner rises slowly. Light a fire on the burner. The flame nozzle diameter is 0.6mm, the flame is thin and straight, the flame length can reach 10-30cm, and the flame temperature can reach 2000-3000℃, which can be used for cutting metal and melting glass.

Embodiment 2

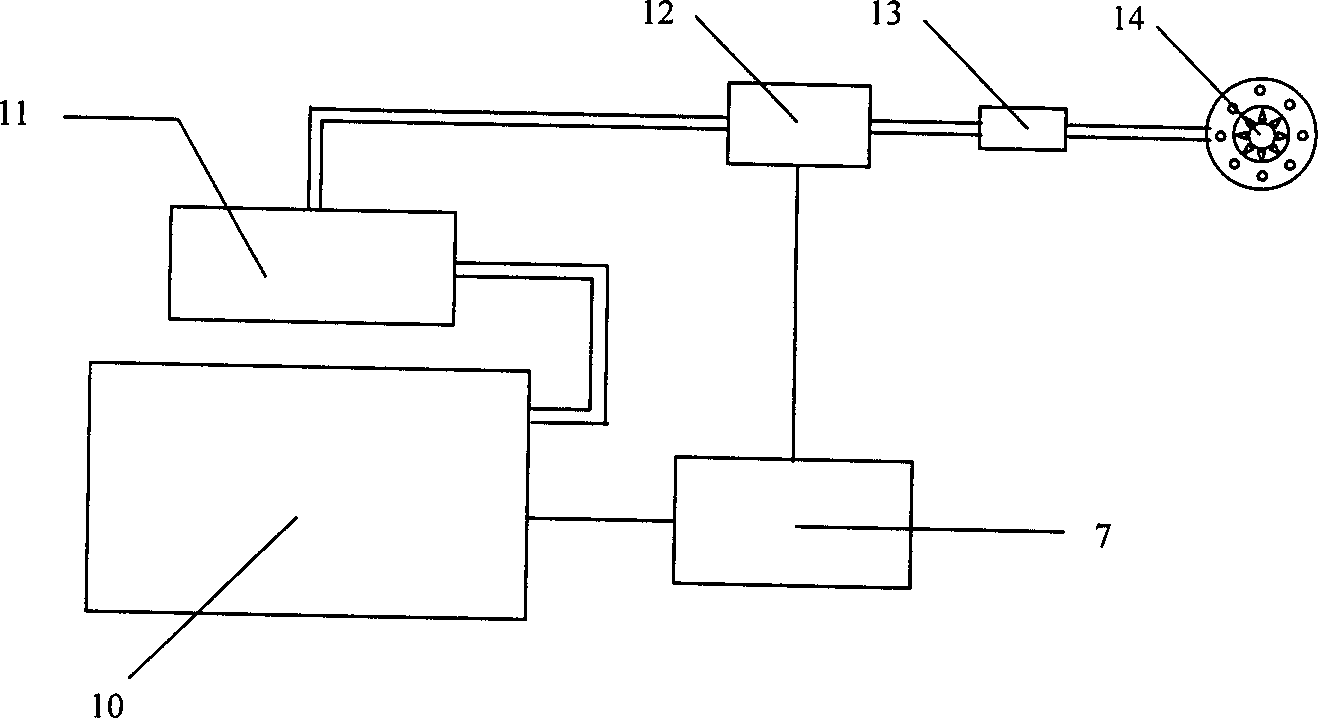

[0034] Embodiment 2: With the equipment and operation sequence of Embodiment 1, the gas outlet diameter of the nozzle port (combustion port) is changed to a smaller nozzle, such as a 0.3mm nozzle, the gas production speed is greater than the exhaust speed, and the barometer pointer continues Ascent, when it rises to the preset 0.08Mpa (at this time, the gas production pressure is about 1.8 atmospheres), the power supply is automatically cut off, and the pointer of the ammeter falls back to zero. The flame at the nozzle mouth continues to burn, and the internal gas continues to be discharged to reduce the internal air pressure, and the pointer gradually falls. When the pointer of the barometer falls back to the set lower limit of 0.03Mpa, the power is automatically turned on again, the pointer of the ammeter returns to 10A or 15A, and the barometer gradually rises again. The air pressure limiter plays the role of limiting the air pressure in the electrolyzer and interlocking th...

Embodiment 3

[0035] Example 3: Taking a water burner with a gas production rate of 2000 liters / hour as an example, follow the operation sequence of Example 1 to make the water burner work stably for more than 10 hours, and the indicator ball of the water level gauge is lowered to close to the lower limit of the water level . At this time, stop the machine temporarily, and after exhausting the remaining gas in the gas pipeline, open the rear inverted Y-shaped water injection port to add about 4 liters of water or distilled water. After sealing, it can continue to be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com