Combustion type waste gas treatment system

a waste gas treatment system and combustion type technology, applied in the direction of combustion types, lighting and heating equipment, incinerator equipment, etc., can solve the problems of affecting the efficiency of the waste gas treatment system, the time of waste gas resident, the waste gas heating scheme, etc., to prevent backfire from spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

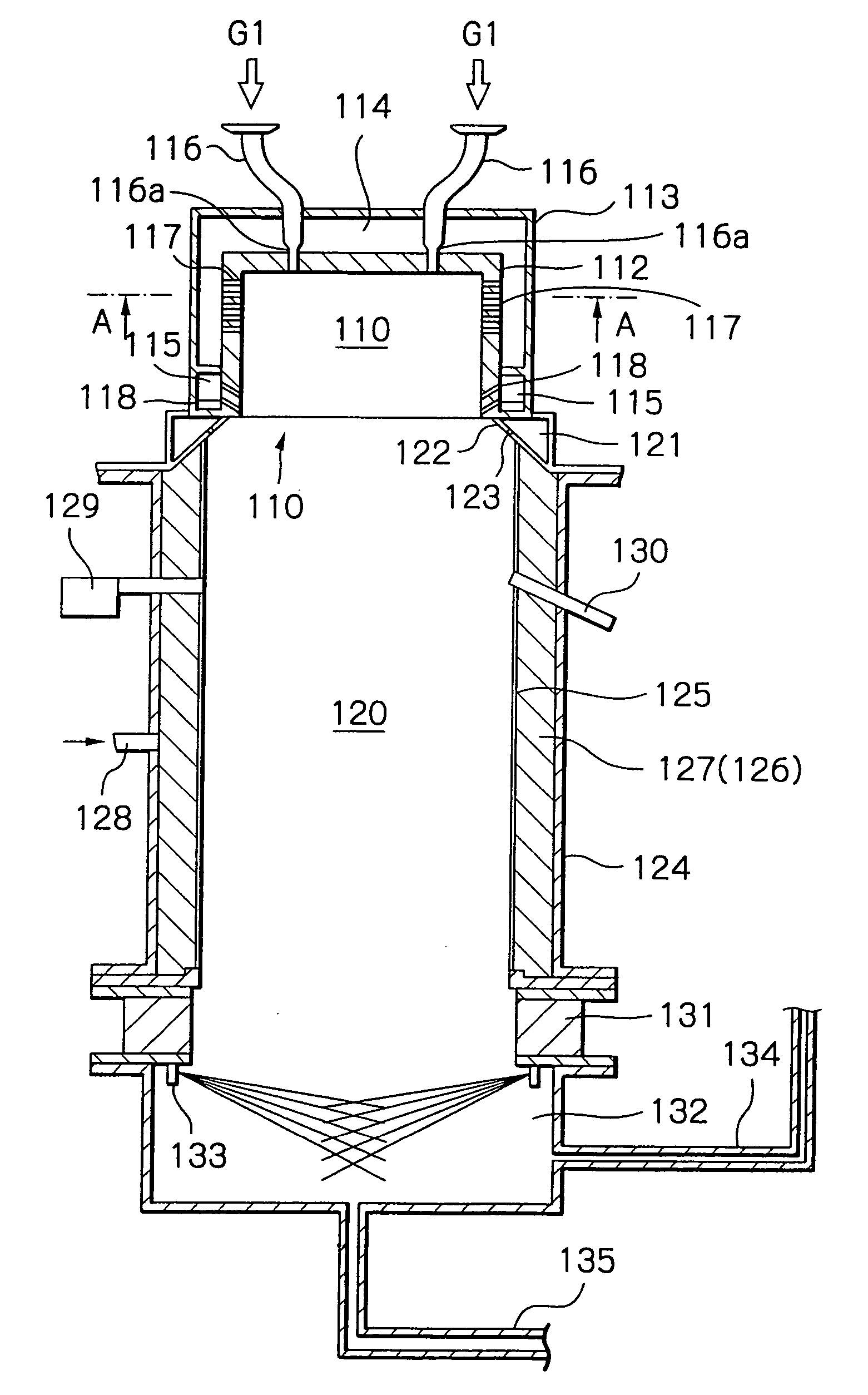

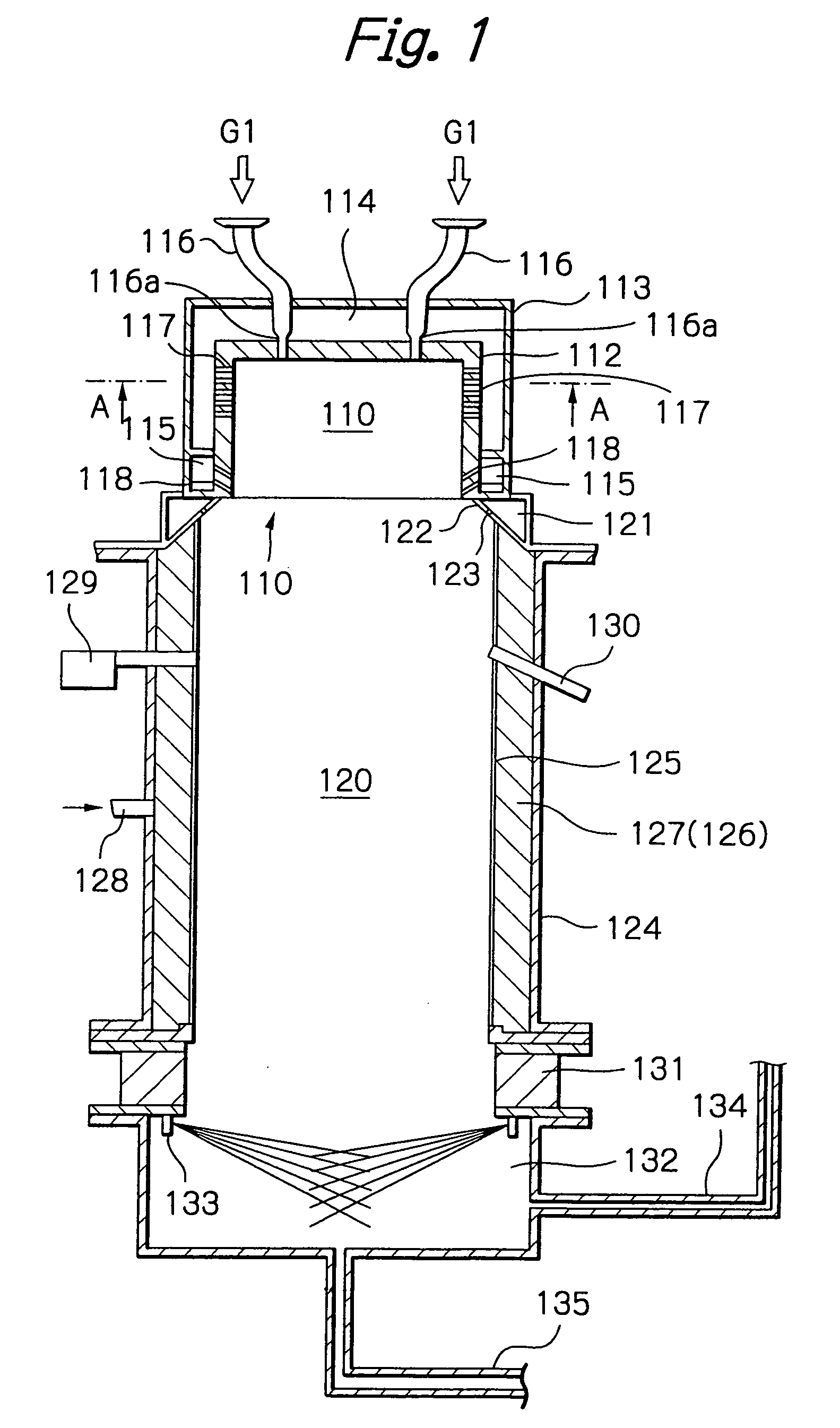

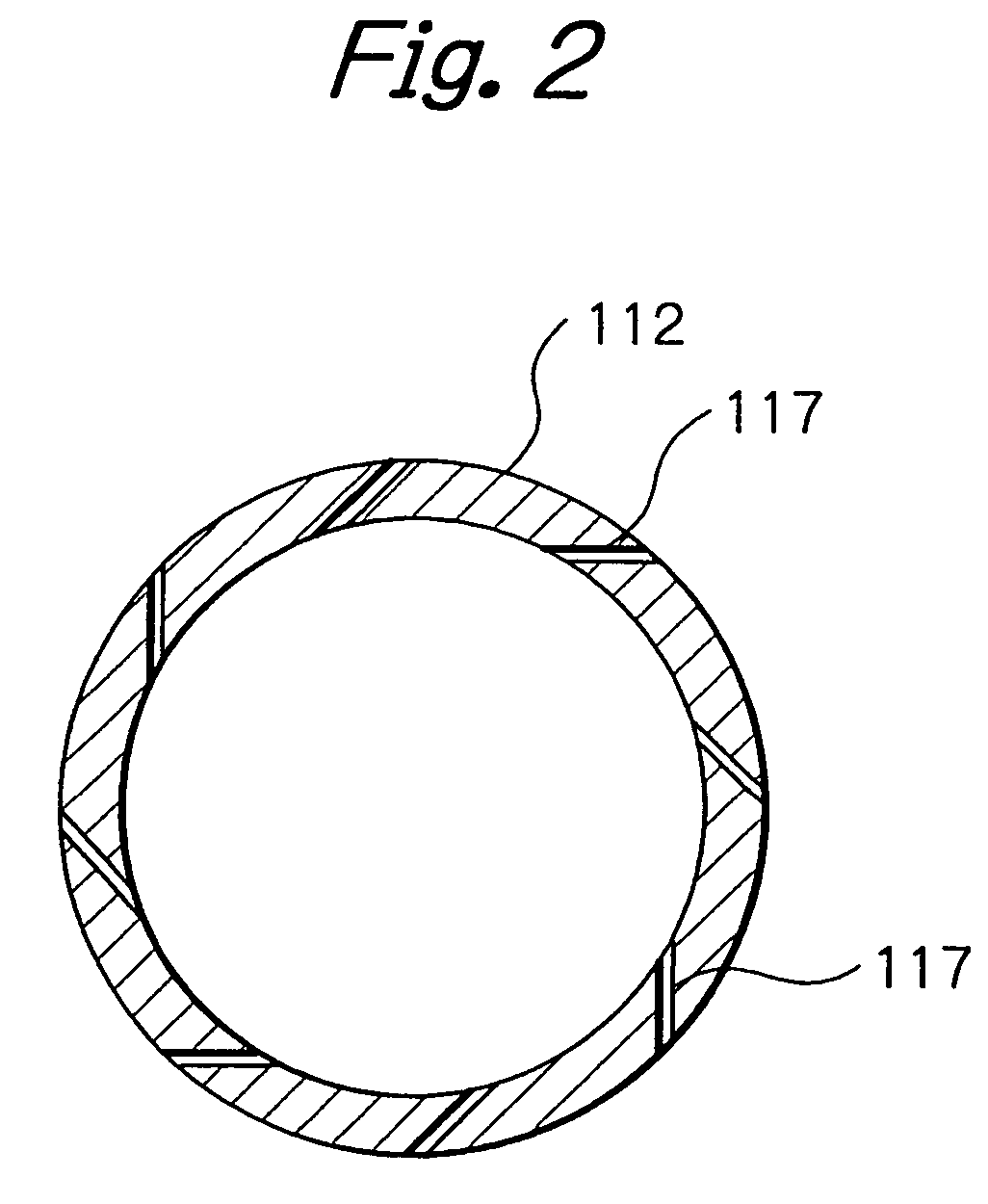

[0046]FIGS. 1 and 2 are diagrams showing the arrangement of the combustion type waste gas treatment system according to the present invention. FIG. 1 is a vertical sectional view, and FIG. 2 is a sectional view taken along the line A-A in FIG. 1. The waste gas treatment system is formed in the shape of a cylindrical closed vessel as a whole. The waste gas treatment system has a burner part 110 in an upper stage and a combustion chamber (combustion reaction part) 120 in an intermediate stage. The waste gas treatment system further has a cooling part 131 and a discharge part 132 in a lower stage. As a cooling medium in the cooling part 131, for example, a liquid, e.g. water, or a gas, e.g. air, is used.

[0047] The burner part 110 has a cylindrical member 112 forming a flame stabilizing portion 111 opening toward the combustion chamber 120. The burner part 110 further has an outer cylinder 113 surrounding the cylindrical member 112 with a predetermined space therebetween. Between the cy...

second embodiment

[0063]FIGS. 10 and 11 are diagrams showing the arrangement of the combustion type waste gas treatment system according to the present invention. FIG. 10 is a sectional view taken along the line E-E in FIG. 11. FIG. 11 is a sectional view taken along the line D-D in FIG. 10. In FIGS. 10 and 11, the same reference numerals as those in FIGS. 1 and 2 denote the same or corresponding portions or members. The combustion type waste gas treatment system according to this embodiment differs from that shown in FIGS. 1 and 2 in that the waste gas inlet pipes 116 are installed on the top of the burner part 110 so that waste gas blown off from openings 116d of the waste gas inlet pipes 116 that open on the inner wall surface of the cylindrical member 112 constituting the burner part 110 forms swirling flows directed obliquely downward in the burner part 110 and the combustion chamber 120.

[0064] As a result of installing the waste gas inlet pipes 116 so that waste gas blown off from the openings ...

third embodiment

[0067] the present invention will be described below with reference to FIGS. 12 to 16. FIG. 12 is a diagram showing a structural example of the combustion type waste gas treatment system according to the present invention. In the figure, arrows A and A, arrows B and B, and arrows C and C are connected together, respectively. In this combustion type waste gas treatment system, hydrogen (H2) gas is used as a gas for combustion. Oxygen (O2) gas is mixed with the hydrogen gas to form combustion flames. Waste gas is introduced into the combustion flames to oxidatively decompose the waste gas. In FIG. 12, a waste gas treatment system body 10 has a burner part 11 and a combustion chamber 12 at the downstream side of the burner part 11.

[0068] An air chamber 13 for holding air (Ae) for combustion is provided around the upper part of the outer periphery of the burner part 11. A fuel gas chamber 14 for holding a mixed gas of hydrogen H2 and oxygen O2 is provided around the middle part of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com