Fuel cell hydrogen supplying system for backup power

A fuel cell and backup power technology, applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve the problems of online replacement of hydrogen bottles and accurate estimation of the remaining pressure of hydrogen bottles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

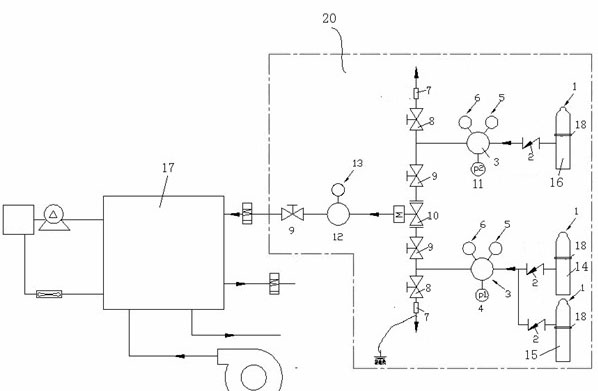

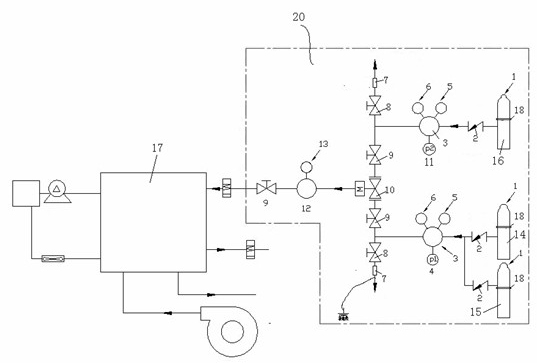

[0025] Such as figure 1 As shown, the fuel cell hydrogen supply system 20 for backup power supply of the present invention includes a main hydrogen supply bottle assembly and a backup hydrogen bottle assembly. It consists of differential pressure valve 10, manual valve 1, emptying valve 8, ball valve 9, low pressure gauge 13, high pressure gauge 5, medium pressure gauge 6, check valve 2, flame arrester 7, high pressure pressure reducing valve 3, low pressure pressure reducing valve Valve 12, stainless steel pipes and other components.

[0026] The main hydrogen supply bottle assembly and the backup hydrogen bottle assembly are respectively connected to the differential pressure valve 10 through the high-pressure pressure reducing valve 3 through the ball valve 9, and connected to the emptying pipe through the emptying valve 8 respectively. P1, P2 pressure sensors 4, 11 are respectively installed on the high-pressure pressure reducing valve 3 in the main hydrogen supply bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com