Back-fire arrestor

A flashback preventer and flame arrester technology, used in burners, gas fuel burners, combustion methods, etc., can solve the problems of inability to prevent, hidden dangers, personal safety threats, etc. The closing performance and service life are improved, the temperature and wear resistance are broken and damaged, and the effect of not easy to break and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

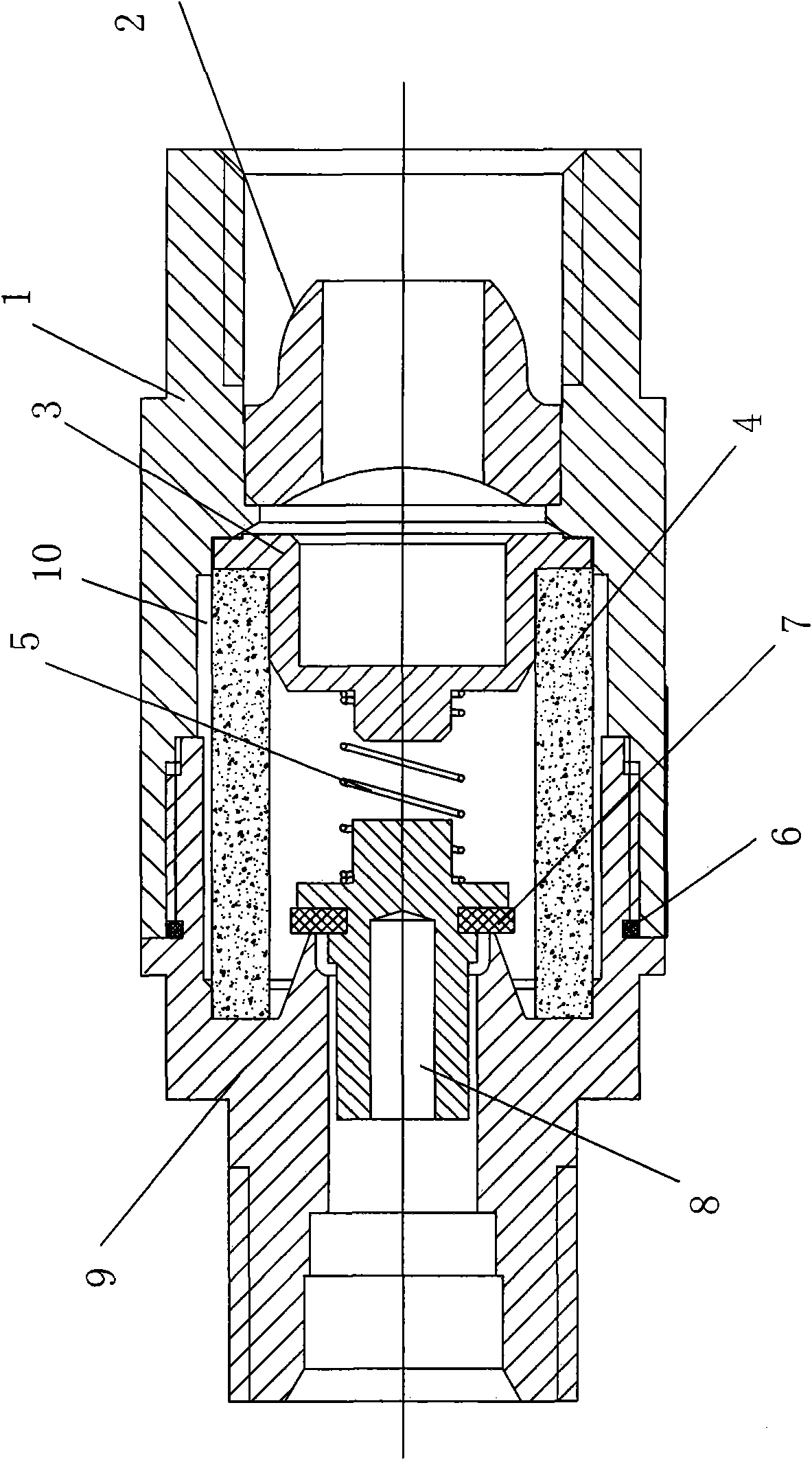

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

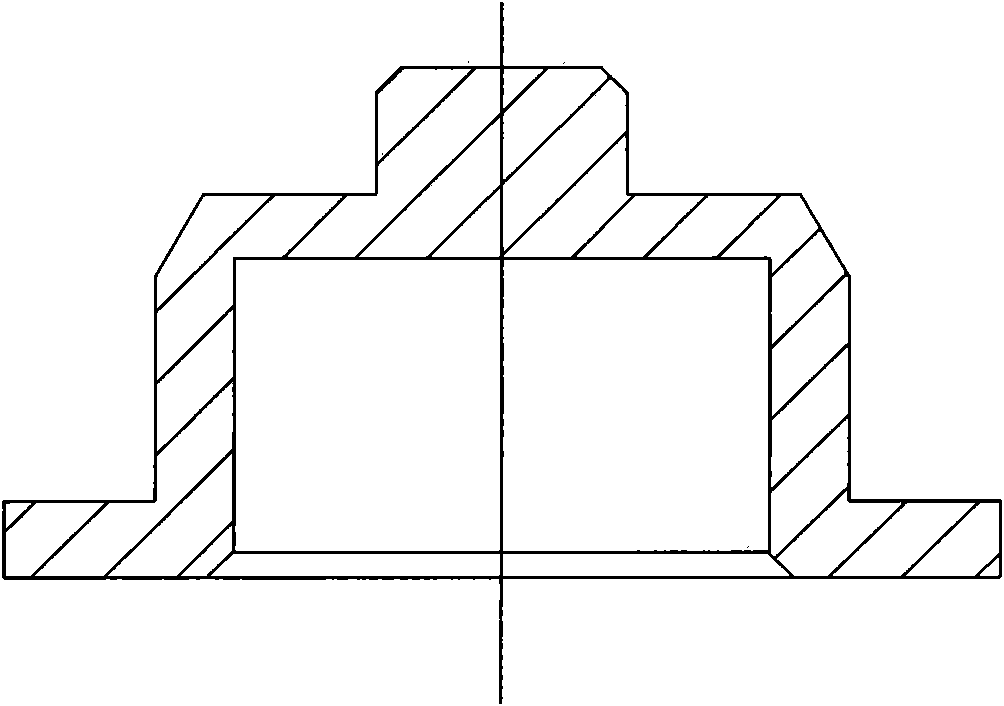

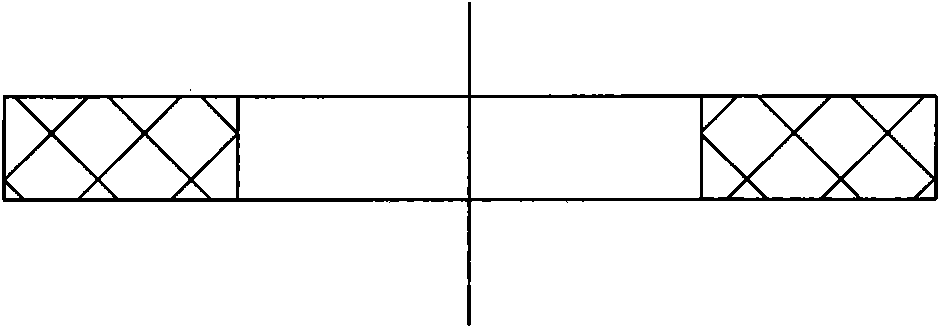

[0017] Such as Figure 1-4 Shown: a flashback preventer, including a main body 1, the main body 1 is made of H62 copper, the input joint 9 and the output joint 2 are threaded on the main body 1, lined with an O-ring 6, installed on the main body 1. A one-way valve in the cavity. The one-way valve is composed of a valve core 8, a valve spring 5 and a spring seat 3. The spring seat 3 is arranged in the cavity of the main body 1. One end of the valve spring 5 is fastened to the head of the spring seat 3. , the other end of the valve spring 5 is in conflict with the valve core 8, and the fire stop tube 4 is located on the spring seat 3. The key point is that the fire stop tube 4 is made of 80-120 mesh stainless steel particles sintered. In this embodiment, the fire stop pipe 4 made by sintering 100-mesh stainless steel particles is used. The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com