Patents

Literature

35results about How to "Not easy to temper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

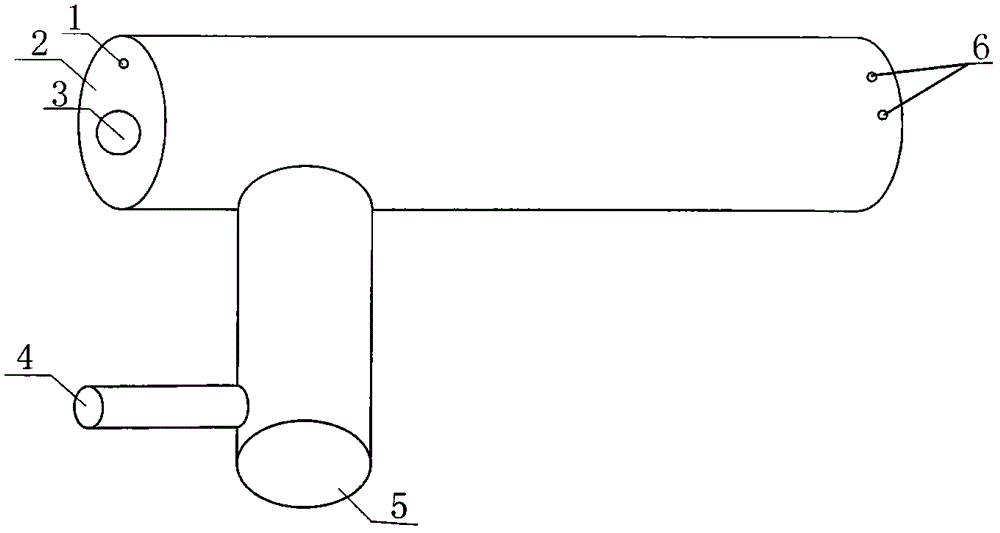

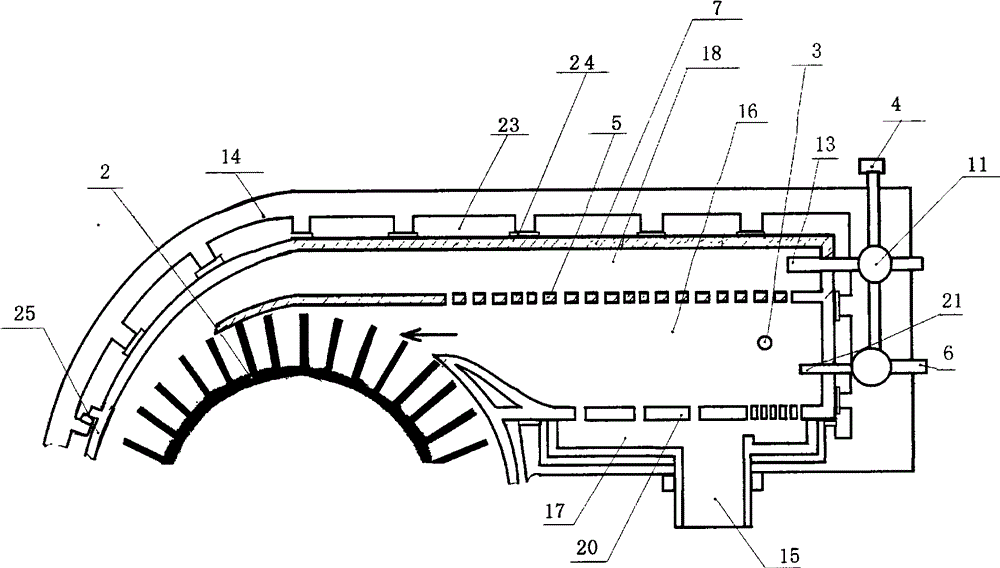

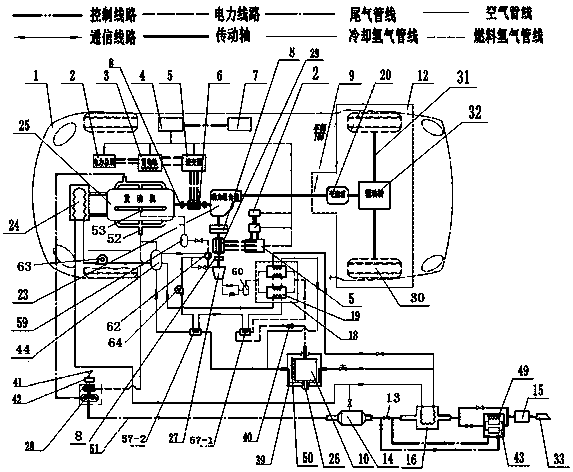

Efficient hydrogen energy vehicle power system for purifying ambient air

ActiveCN106915235AReduce consumptionIncrease motivationHybrid vehiclesInternal combustion piston enginesPower combinerEngineering

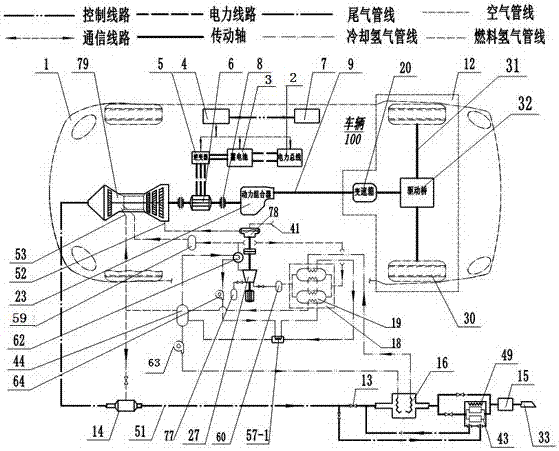

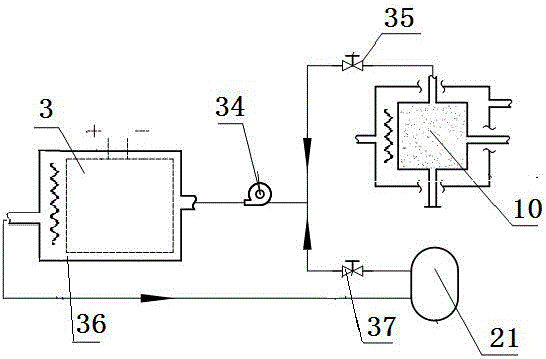

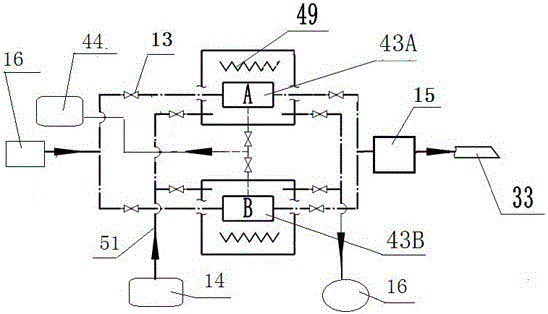

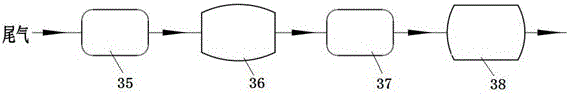

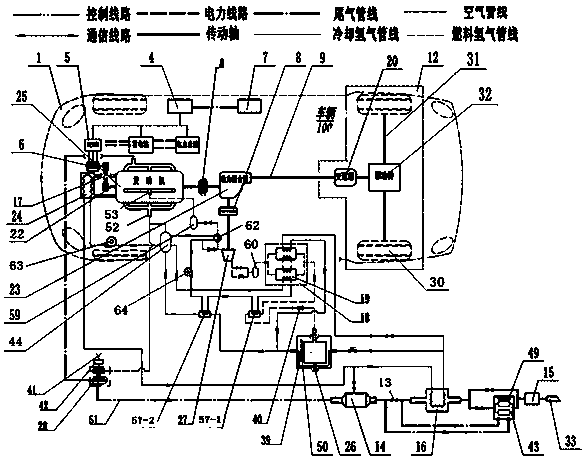

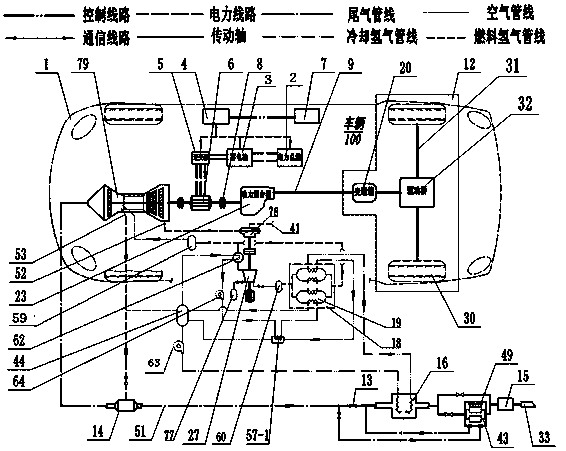

The invention relates to an efficient hydrogen energy vehicle power system with an ambient air purifying function. The efficient hydrogen energy vehicle power system comprises a drive system, a gas turbine, a high pressure hydrogen storage tank, a hydrogen compression unit, a hydrogen gas surge tank, an inverter, an electric-power generator, an expander, a storage battery and an exhaust gas treating and discharging system. The high pressure hydrogen storage tank is connected to an inlet of the expander, one path of an outlet of the expander is connected to a hydrogen inlet through a cold capacity recovery device and the hydrogen gas surge tank, and the other path is connected to the inlet of the expander through a hydrogen compression unit and an intermediate tank. A power combiner is connected with the gas turbine and / or the electric-power generator, according to the technical scheme, the gas turbine is replaced with a hydrogen fuel engine, and the power combiner is connected with the drive system through a drive shaft. According to the efficient hydrogen energy vehicle power system with the ambient air purifying function, the gas turbine is combined with the electric-power generator, so that work efficiency of the hydrogen energy vehicle power system is improved. By recycling of exhaust gas heat, air pollution is reduced, and the natural environment can be protected easily.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

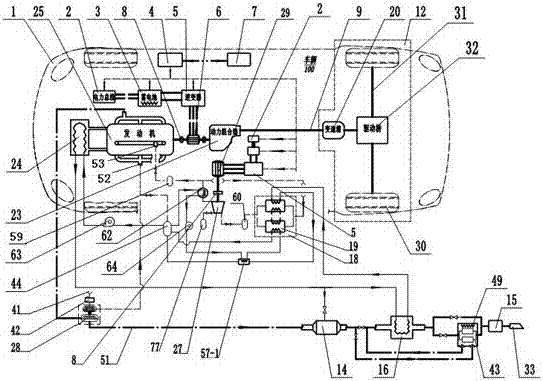

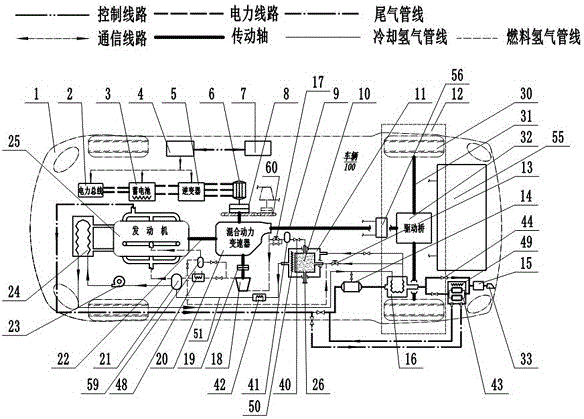

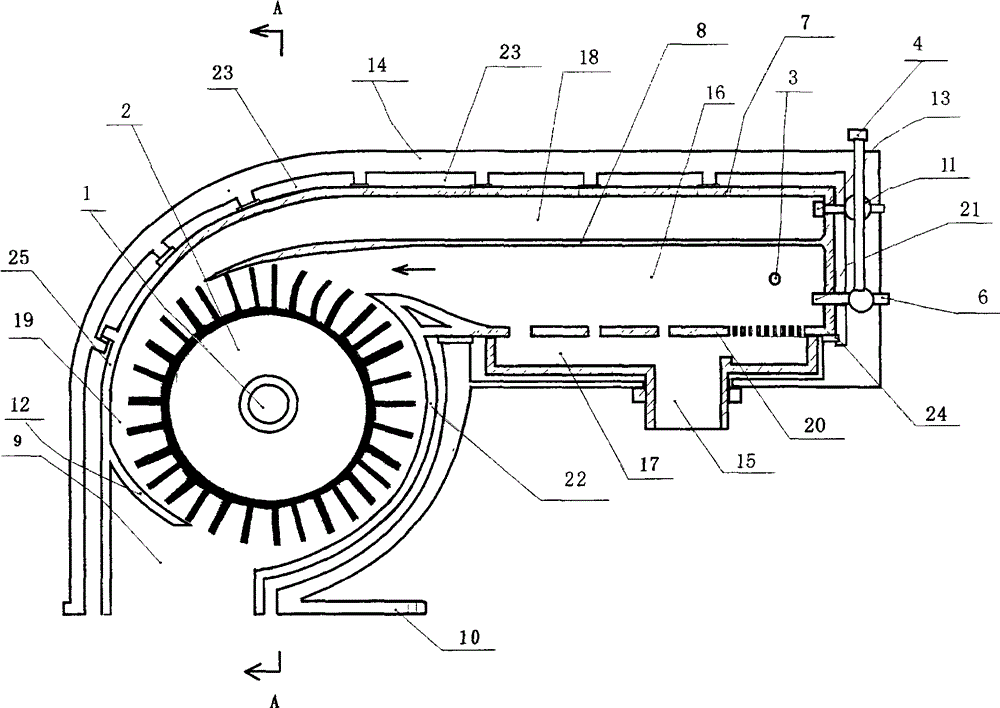

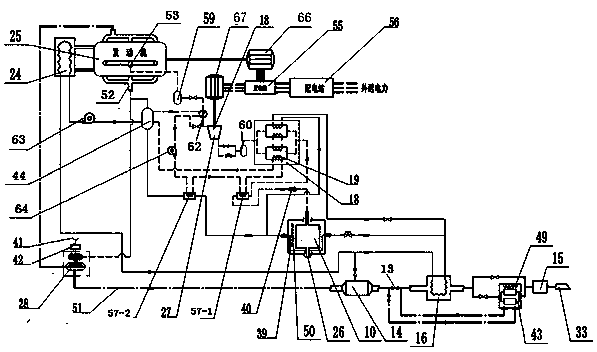

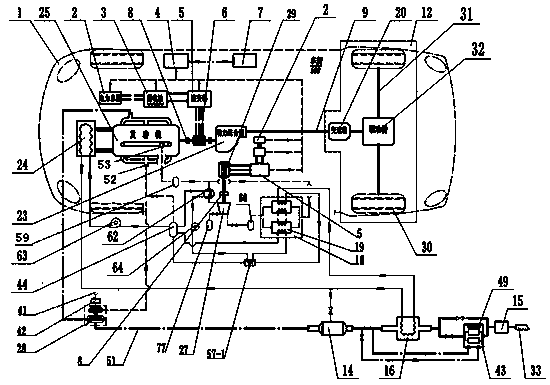

Hybrid power system with waste heat recovery function and environment air purification function and for hydrogen vehicle

ActiveCN106627090AImprove efficiencyFunction increaseHybrid vehiclesAir-treating devicesAtmospheric pollutionRecovery function

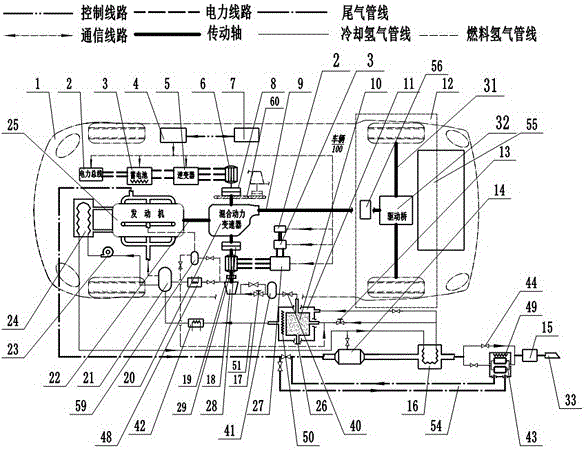

The invention relates to a hybrid power system with a waste heat recovery function and an environment air purification function and for a hydrogen vehicle. The hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle comprises a vehicle body, a transmission system, a hydrogen fuel engine, a hybrid power transmission, a metal hydride storage tank, a turbine, a catalyst, a high-pressure surge tank, a hydrogen buffering tank and the like. The metal hydride storage tank is connected to an inlet of the turbine through the high-pressure surge tank. An outlet of the turbine is connected to an inlet of the hydrogen fuel engine through the hydrogen buffering tank or a high-pressure hydrogen buffering tank. An outlet of the hydrogen fuel engine is connected to a discharge outlet through the catalyst, a tail gas heat exchanger, a residual hydrogen absorption unit and a tail gas zero-stage purifier. The hydrogen fuel engine is connected with the hybrid power transmission through a power output shaft. According to the hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle, the hydrogen fuel engine, the turbine and an exhaust gas waste heat recovery and purification system are combined to form the hybrid power system for the automobile, chemical energy of hydrogen is sufficiently used, various kinds of heat energy in the process is recovered, and the working efficiency of the power system is improved; and atmospheric pollution is avoided, the environment air is purified, and protection of the natural environment is facilitated.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

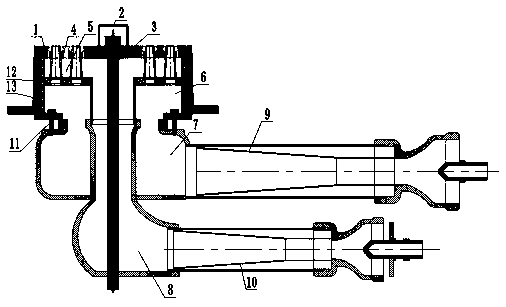

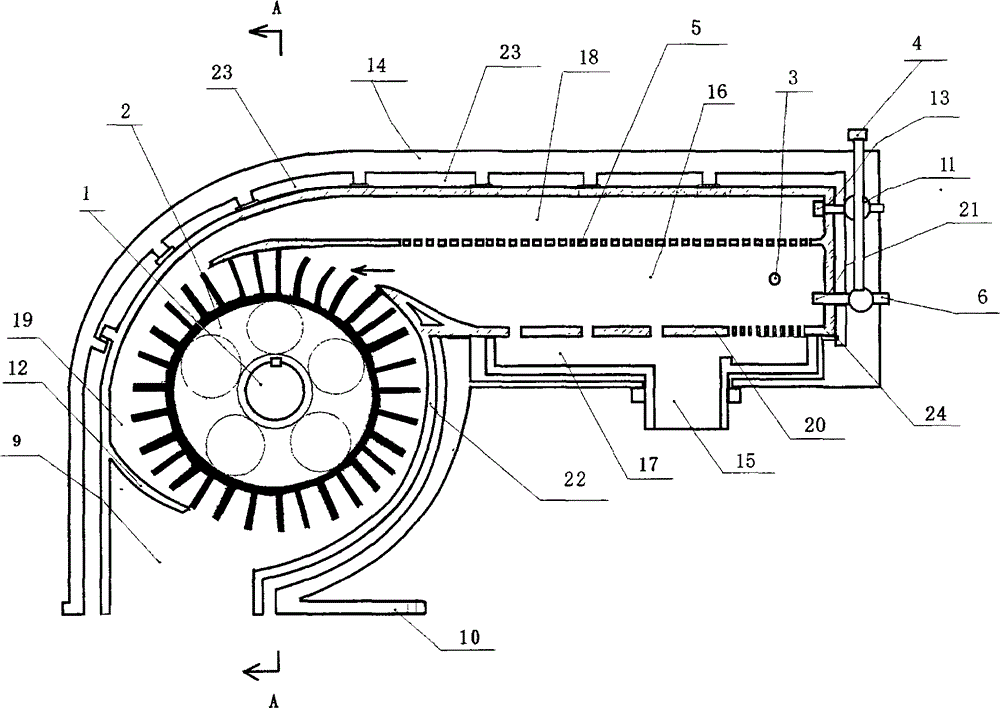

Hydrogen energy vehicle power system for ambient air purification

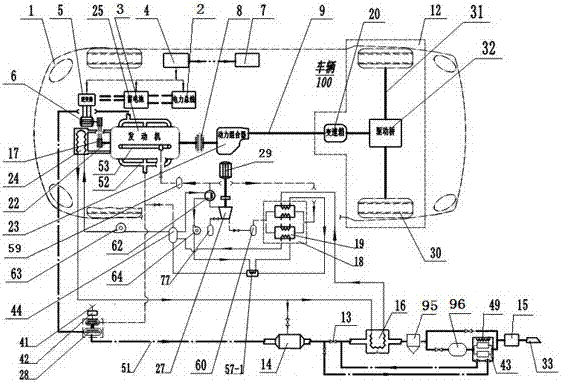

ActiveCN106837529AOvercome wasteOvercome environmental pollutionInternal combustion piston enginesFuel supply apparatusPower combinerEngineering

The invention relates to a hydrogen energy vehicle power system for ambient air purification. The hydrogen energy vehicle power system comprises a transmission system, a hydrogen fuel engine, a metal hydride storage tank, a hydrogen compression unit, a hydrogen stabilized tank, an inverter, a, electric-generator, an expansion machine, a storage battery and an exhaust gas disposal system. The storage battery is electrically connected with a power bus and the inverter, and the inverter is electrically connected with the electric-generator; the metal hydraulic storage tank is connected with the hydrogen fuel engine through the hydrogen compression unit and the hydrogen stabilized tank, and an exhaust outlet of the hydrogen fuel engine is connected with the exhaust gas disposal system through a turbo charger; the hydraulic fuel engine or / and the number one electric-generator is / are connected with a power combiner, the expansion machine is connected with the power combiner, and the power combiner is connected with the transmission system through a transmission shaft. By the combination of the hydrogen fuel engine with the electric-generator, operation efficiency of the hydrogen energy vehicle power system is improved; by recycling exhaust heat, atmospheric pollution is reduced, and natural environment is favorably protected.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

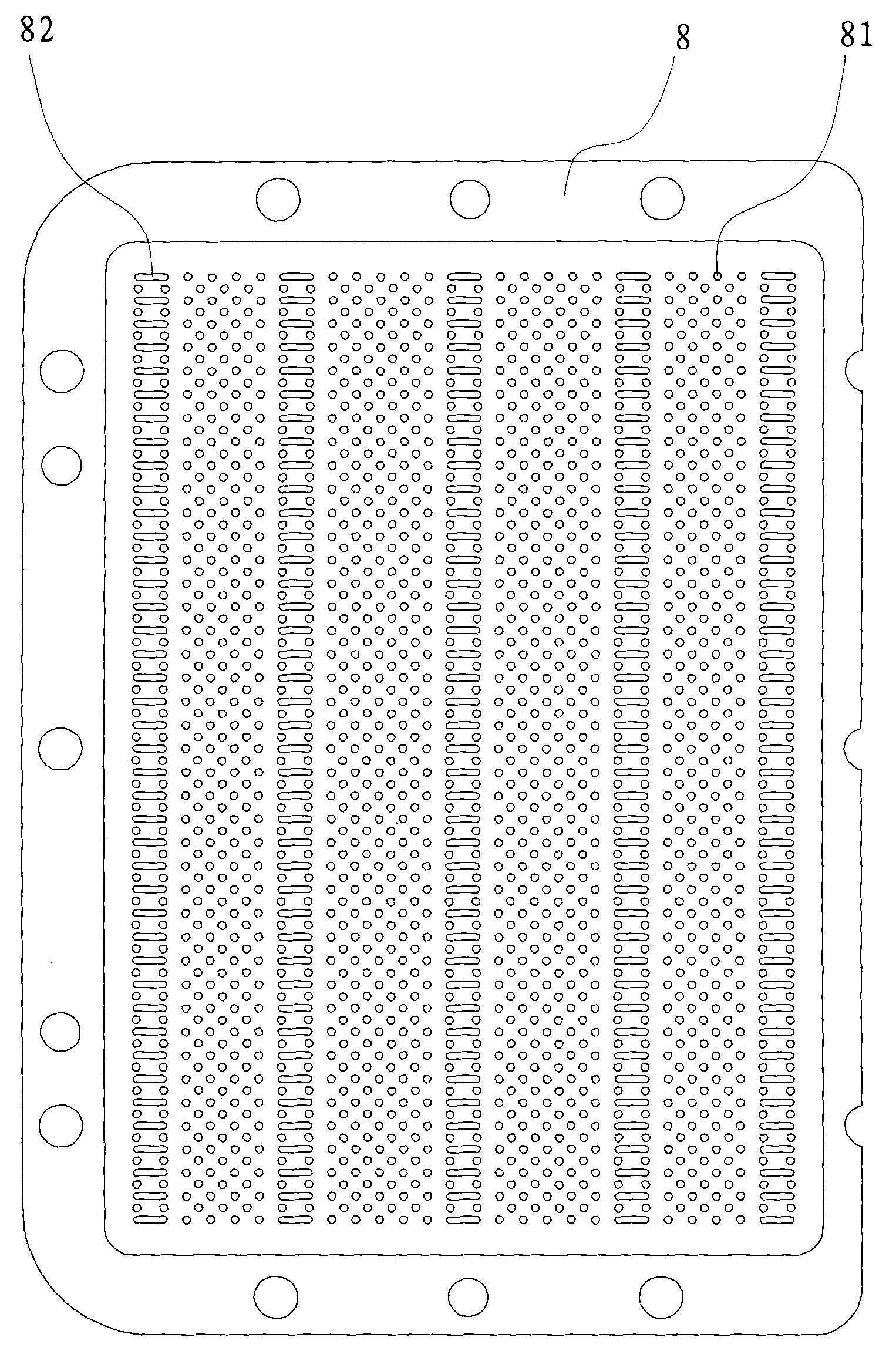

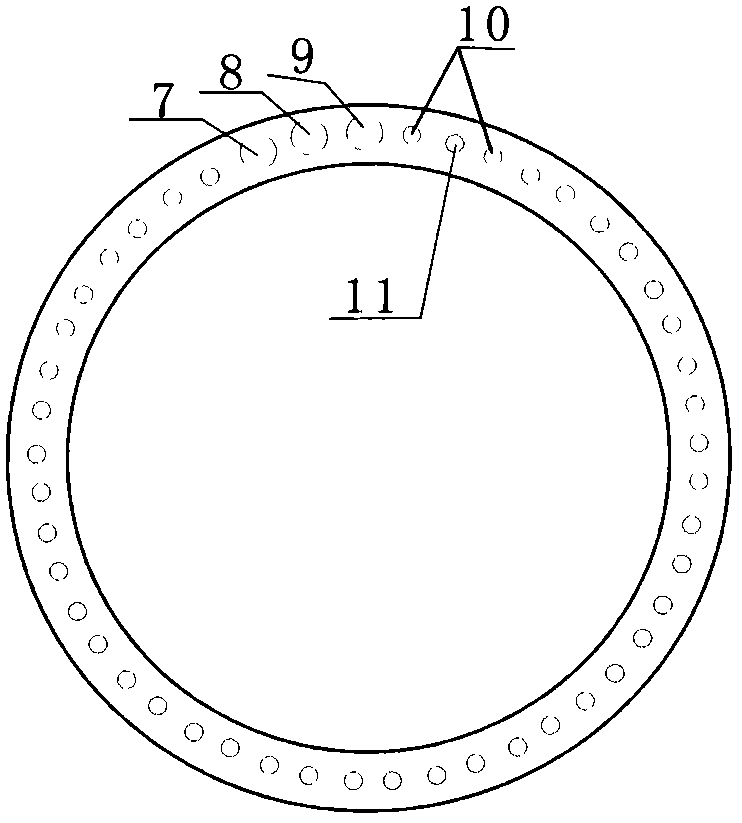

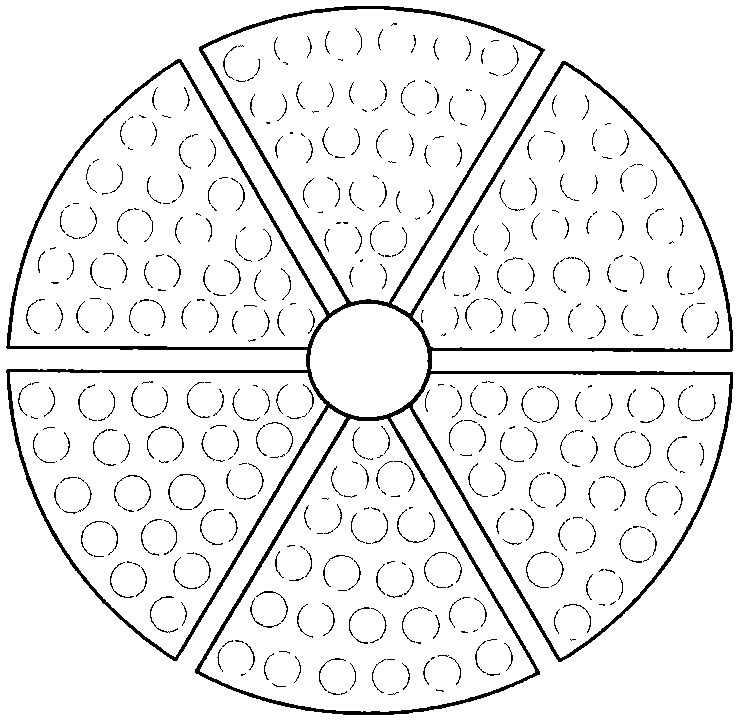

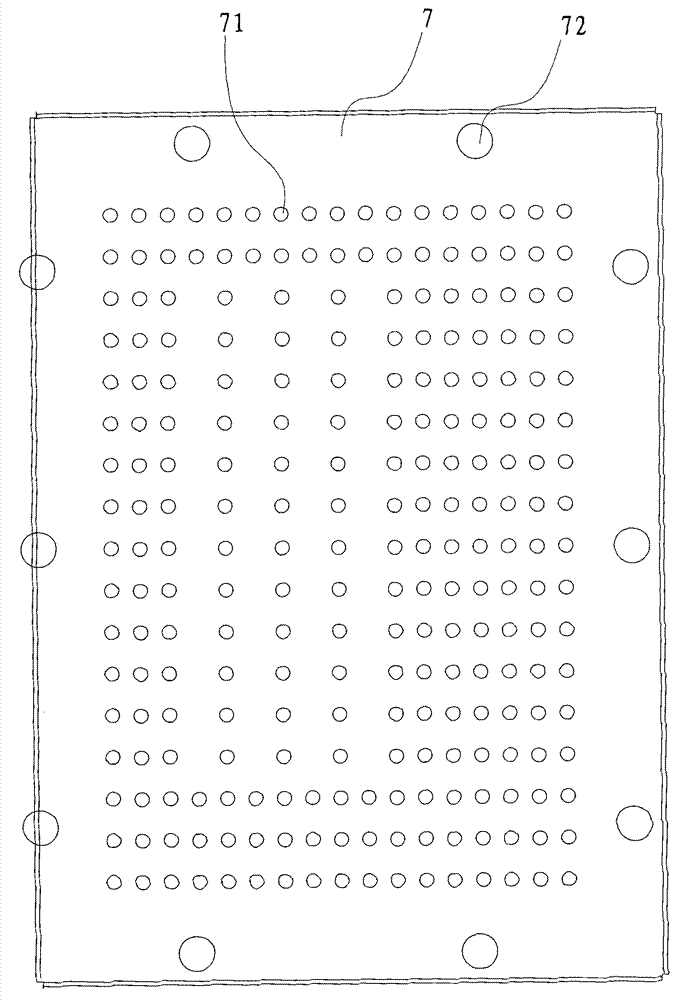

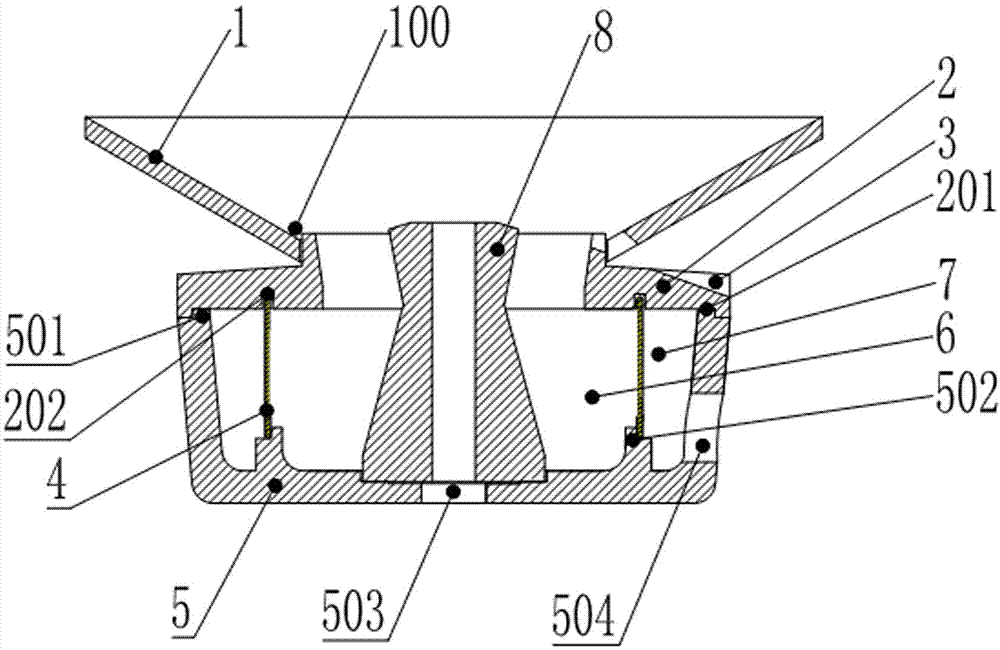

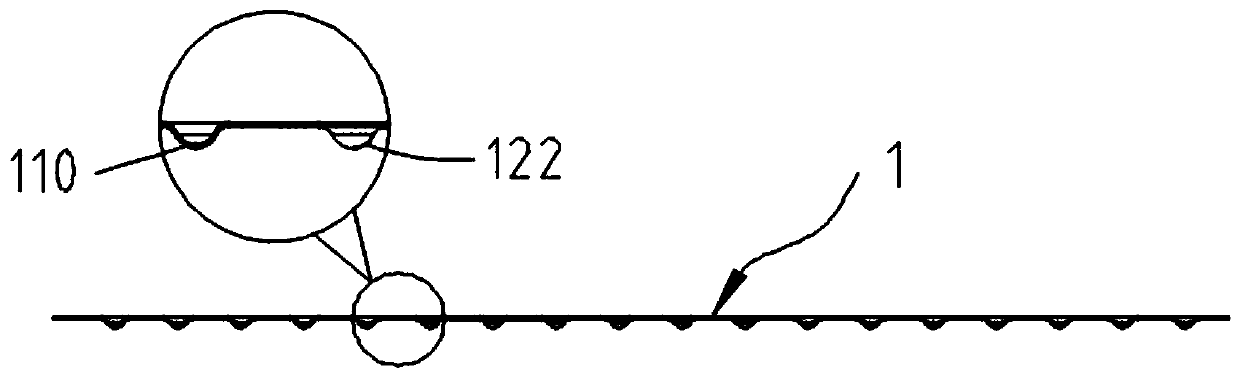

Fire cover, burner and gas stove

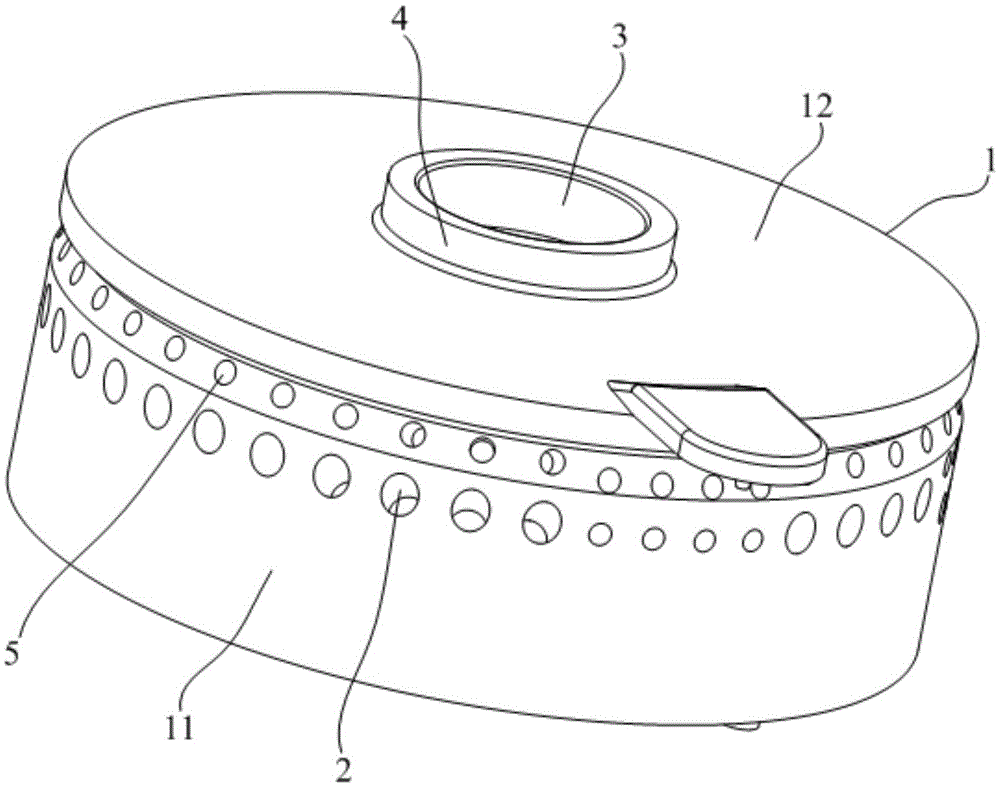

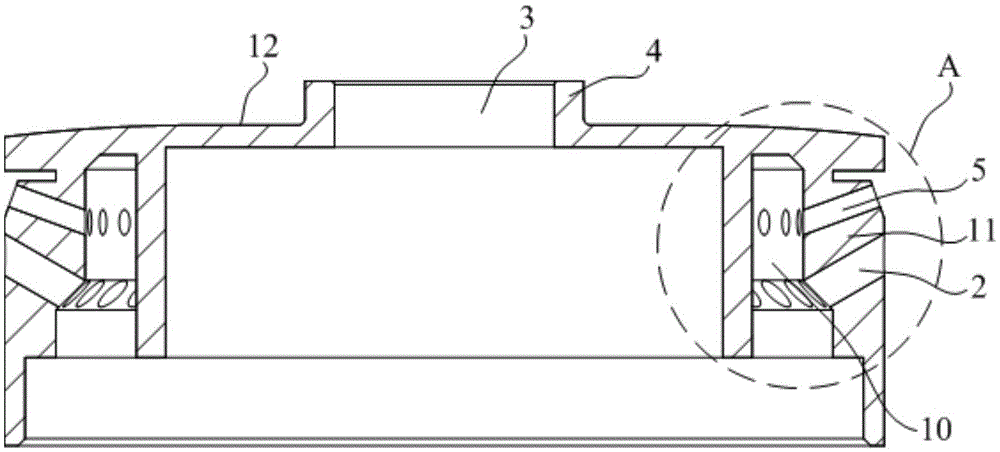

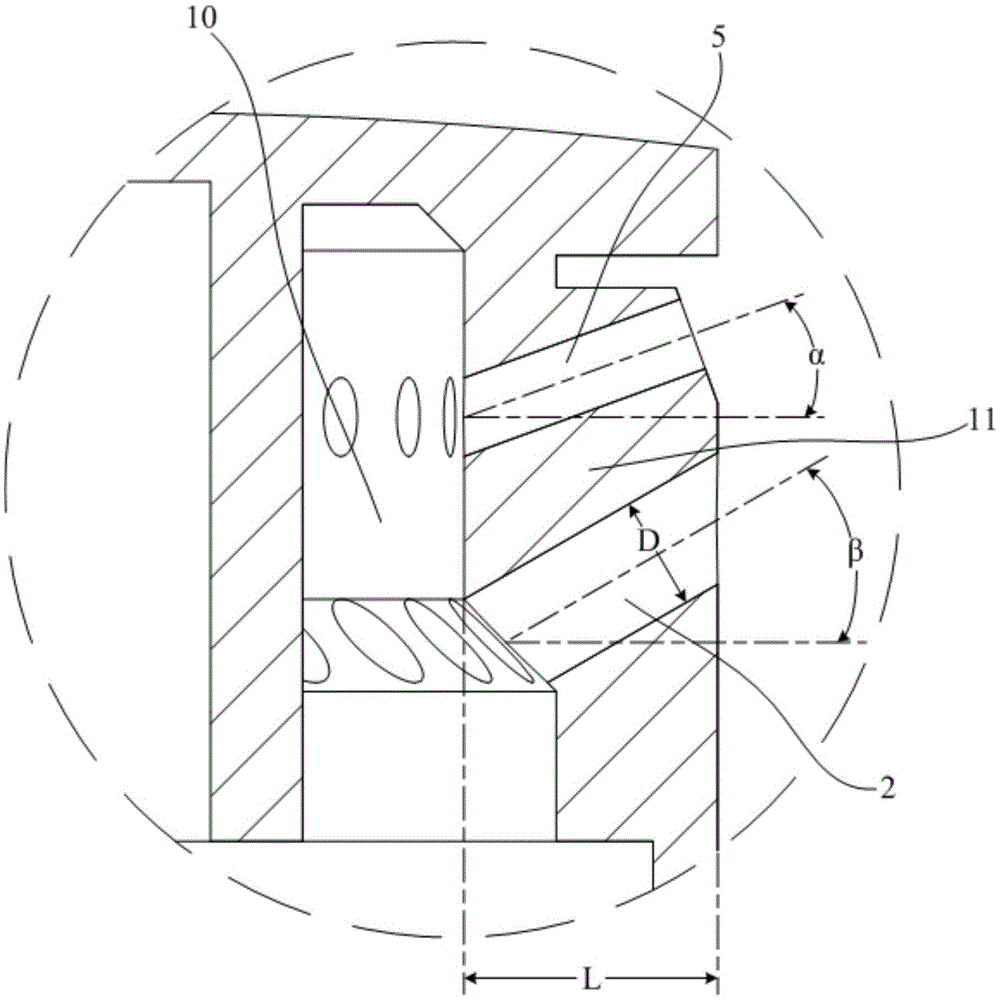

ActiveCN105605576ANot easy to temperImprove the safety of useDomestic stoves or rangesGaseous fuel burnerBack-fireEngineering

The invention discloses a fire cover, a burner and a gas stove. The fire cover is used for the burner and comprises a fire cover body which is provided with main fire holes, and the ratio of the thickness wall of the position, provided with the main fire holes, of the fire cover body and the hole diameter of the main fire holes is larger than or equal to 2.85. According to the technical scheme, by means of the fire cover, the burner and the gas stove, the back-fire phenomenon of the main fire holes of the fire cover can be avoided, and therefore the use safety of the burner with the fire cover is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

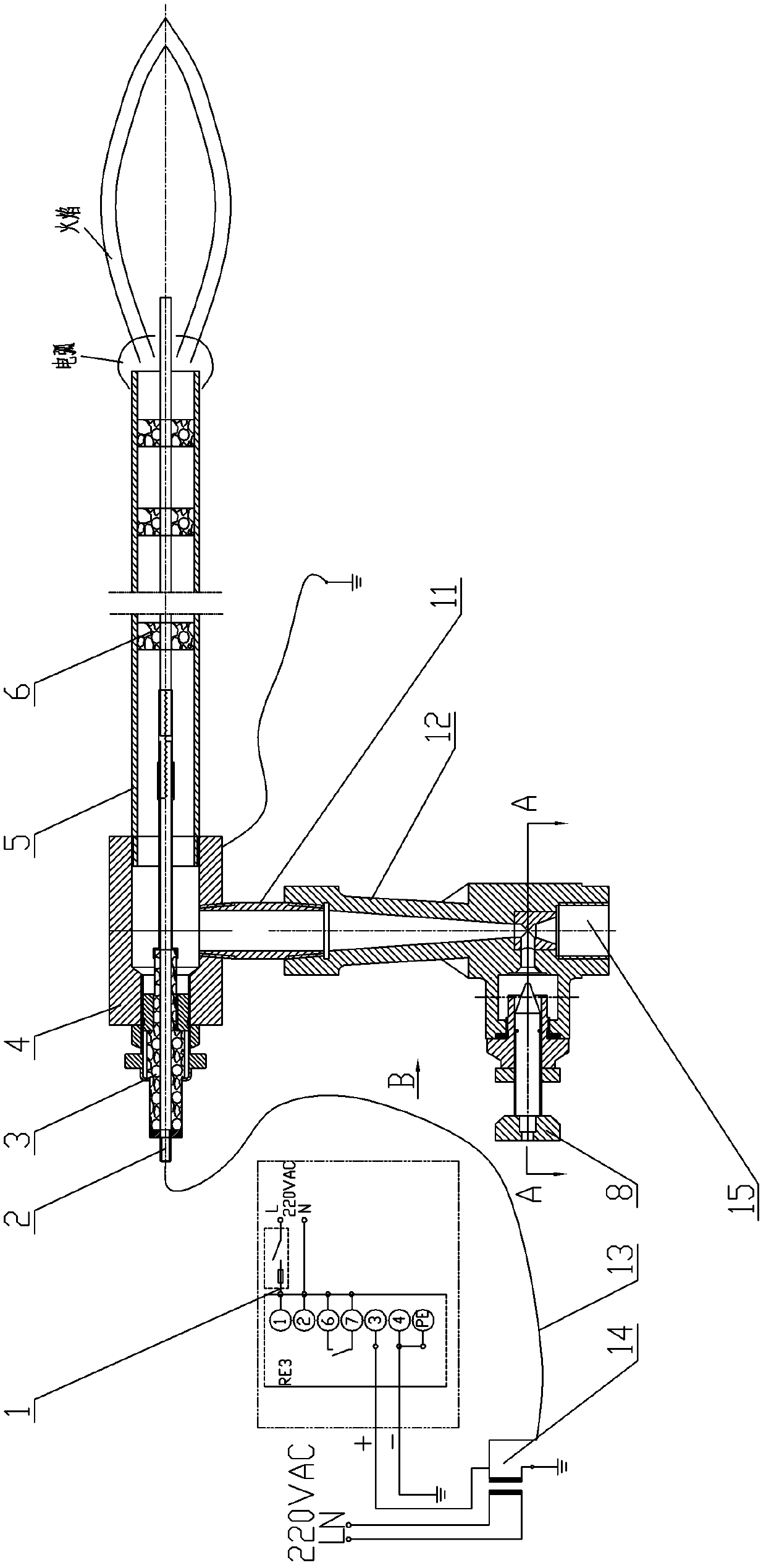

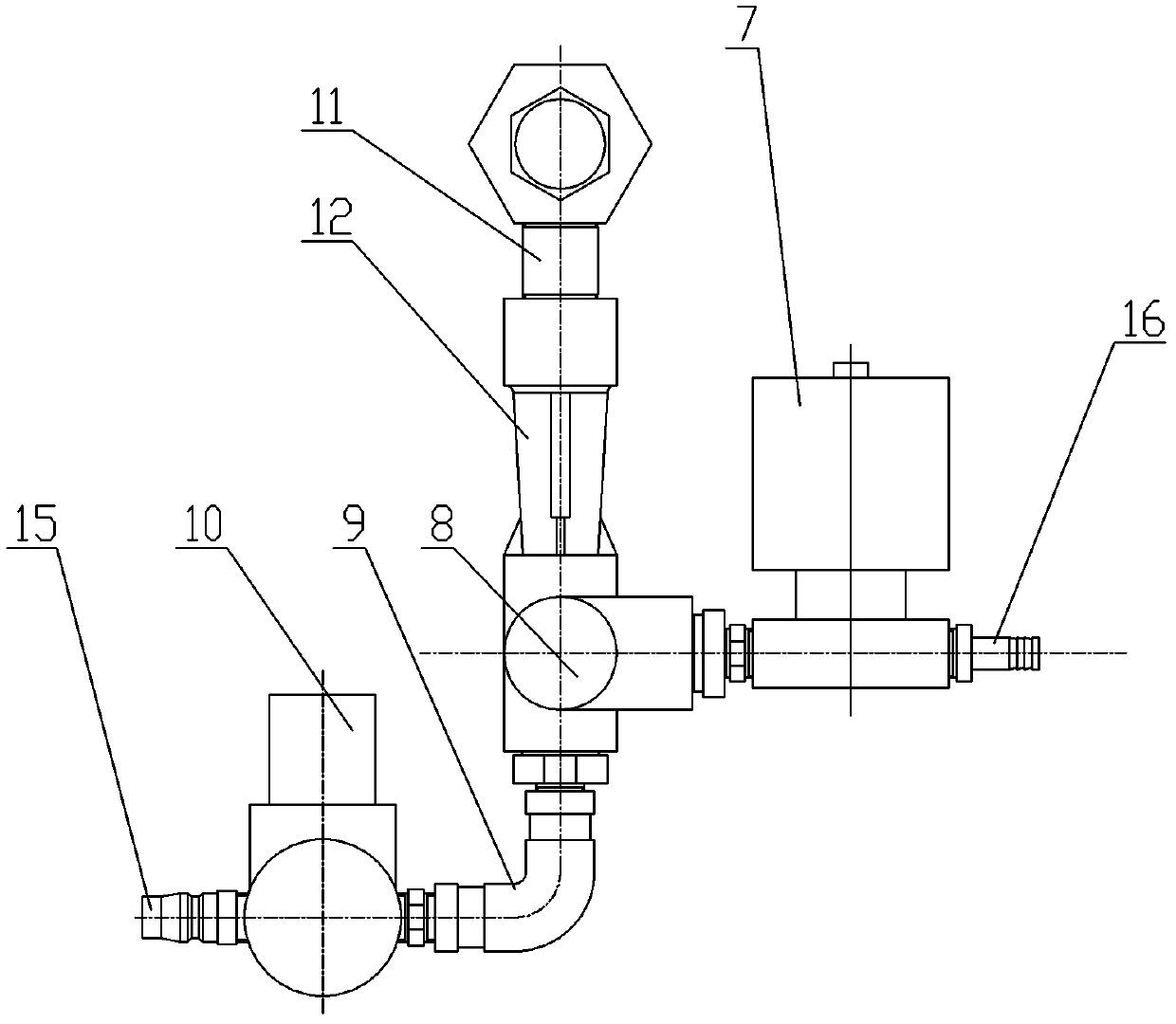

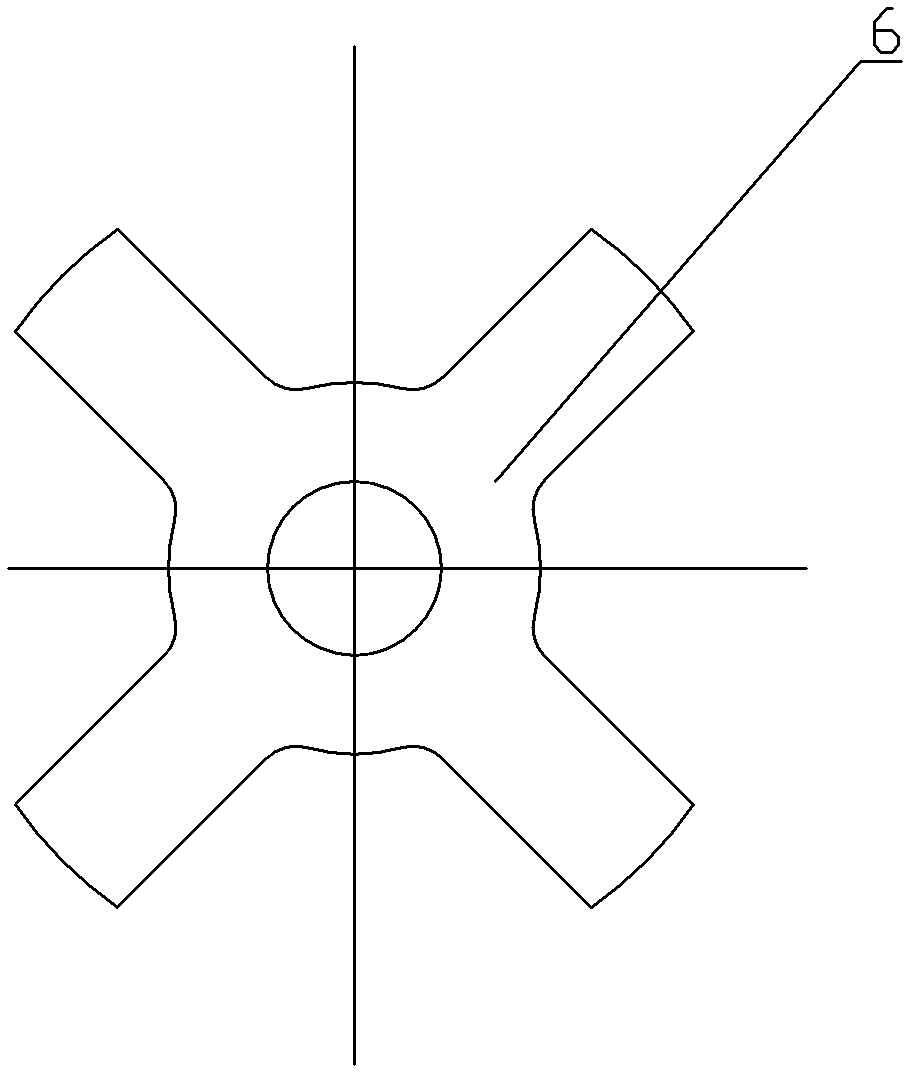

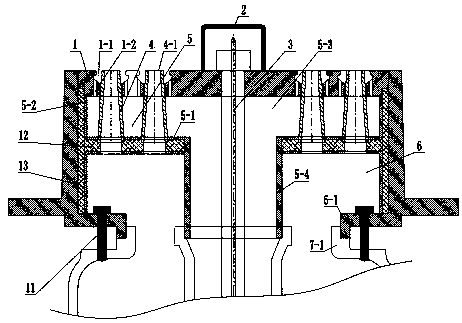

Ignition and flame detection integrated device

InactiveCN102607056ASimple structureCompact structureElectric spark ignitersPhotometry using electric radiation detectorsAudio power amplifierBiochemical engineering

The invention relates to an ignition and flame detection integrated device which comprises a mounting base. The device is characterized in that a connecting pipe is arranged on the side wall of the mounting base and is connected with an ejector, the lower ends of the ejector are respectively provided with a fuel gas inlet and a compressed air inlet, an electrode ceramic base is fixed at one end of the mounting base, the other end of the mounting base is provided with a guide pipe, an igniting electrode / ion probe is fixed on the electrode ceramic base, one end of the igniting electrode / ion probe passes through the mounting base and the guide pipe, extends out of the guide pipe and finally reaches an outlet of the guide pipe, the other end of the igniting electrode / ion probe is connected with a secondary side of an ignition transformer through a high-voltage lead, a primary side of the ignition transformer is connected with a power supply, the secondary side is earthed, the secondary side of the ignition transformer, which is at the end opposite to the igniting electrode / ion probe, is connected with a flame amplifier and the flame amplifier is earthed. The ignition and flame detection integrated device is simple, compact and reasonable in structure, convenient to mount, practical and easy to operate, has good burning effect and low possibility of backfire, is safe and reliable and can perform flame formation and detection at the same time.

Owner:WUXI WEILIT MARINE BOILER

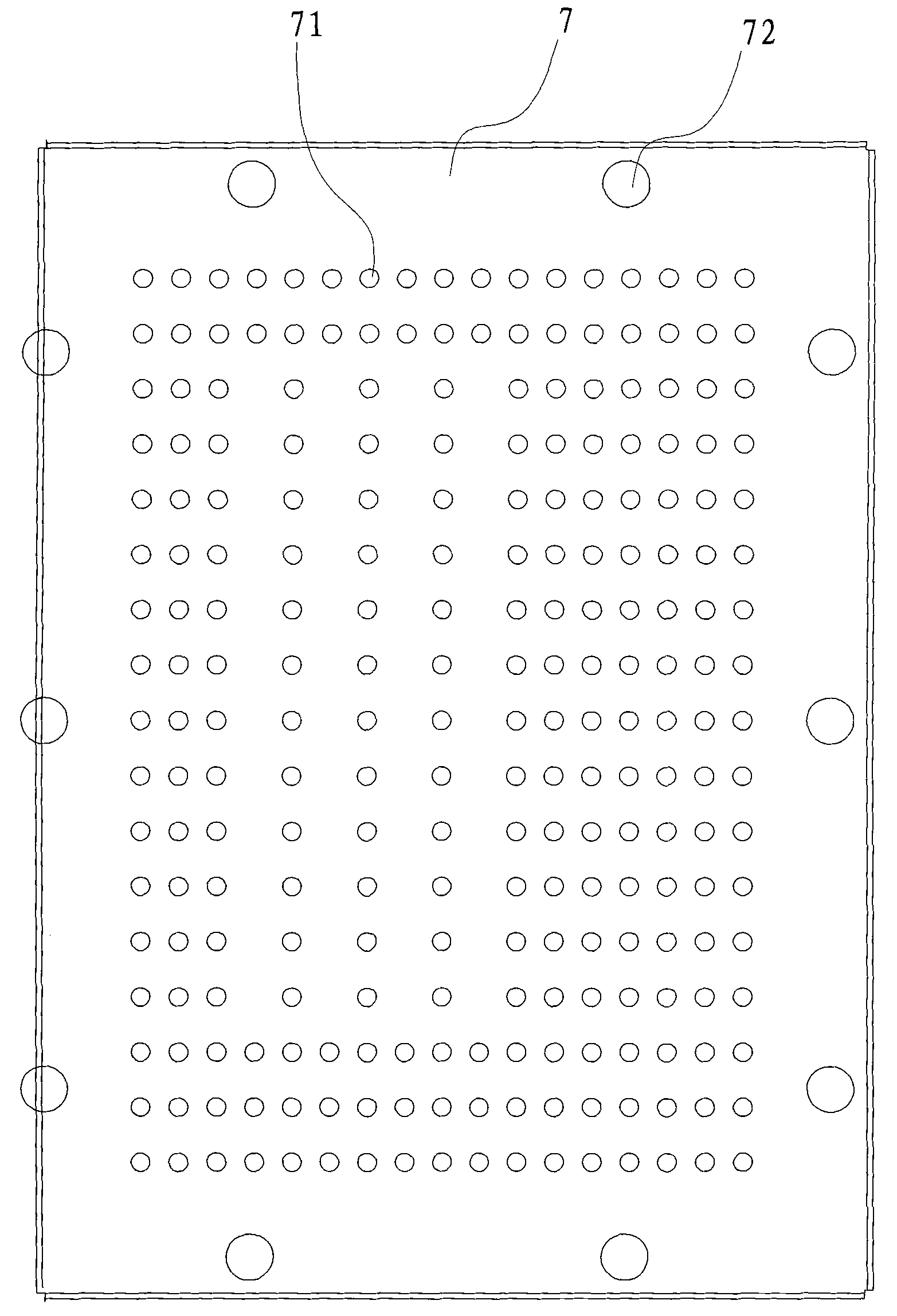

Burner

The invention relates to a burner, which comprises a gas mixing chamber for mixing gas and air, and is characterized in that: a cover plate is detachably arranged on the top of the gas mixing chamber; and a plurality of fire holes which allow flame to pass through are distributed on the cover plate at intervals. Compared with the prior art, the burner has the advantages that: the cover plate is arranged on the top of the gas mixing chamber, is provided with the fire holes and can effectively buffer the pressure of the flame jetted from jet orifices, so that floating flame is formed on the surface of the cover plate; and the whole burner is difficult to temper.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

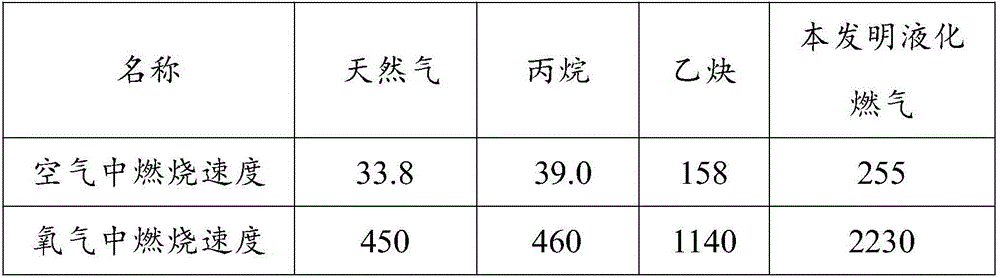

High-precision natural gas cutting gas

InactiveCN101985573ALow costGas cost increasesGaseous fuelsGas flame welding apparatusAnhydrous ethanolRosin

The invention discloses a high-precision natural gas cutting gas. Natural gas is taken as a major ingredient. Catalysis assistant is added into the natural gas and is composed of the following components at volume ratio: 25-28% of solvent oil, 14-18% of anhydrous ethanol or carbinol, 16-20% of isopropanol or n-butyl alcohol, 14-16% of dimethylbenzene, 18-22% of rosin water and 1.5-2% of Catoc-ene; the ratio of the natural gas to the catalysis assistant is characterized is that 10-12 ml of the catalysis assistant is added in each cube of natural gas.

Owner:CHONGQING HENGSHENG ENERGY DEV

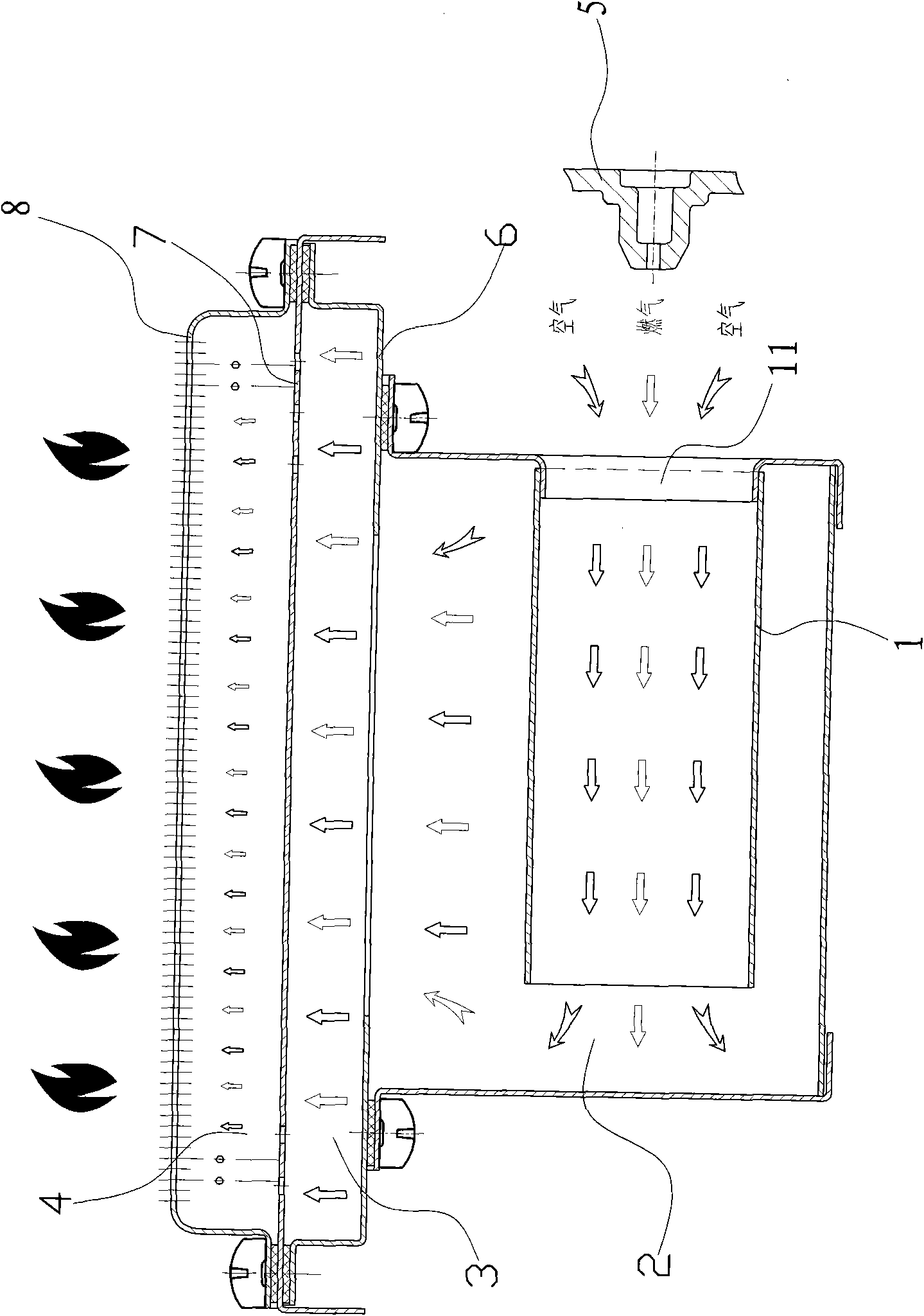

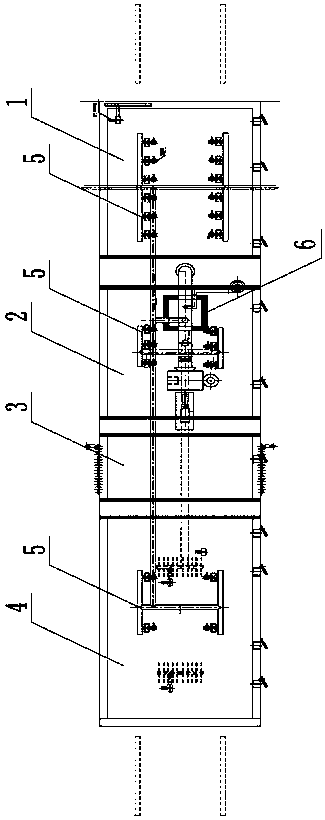

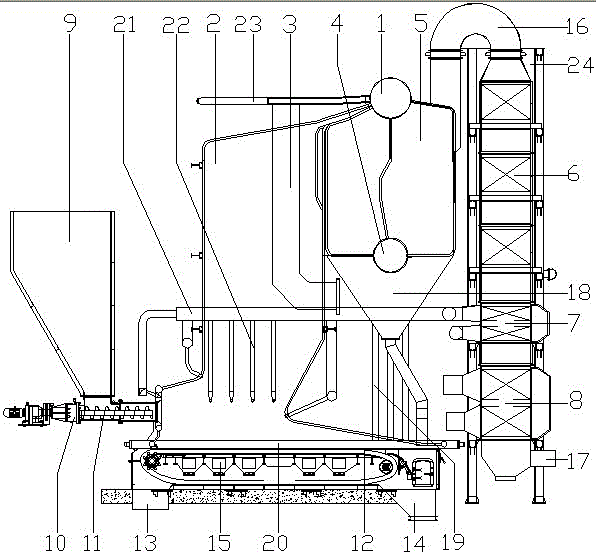

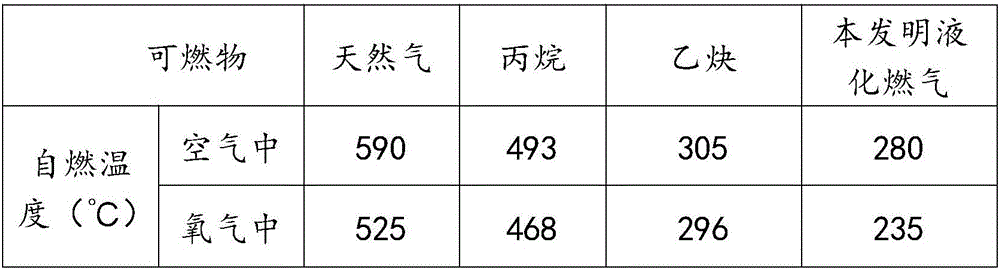

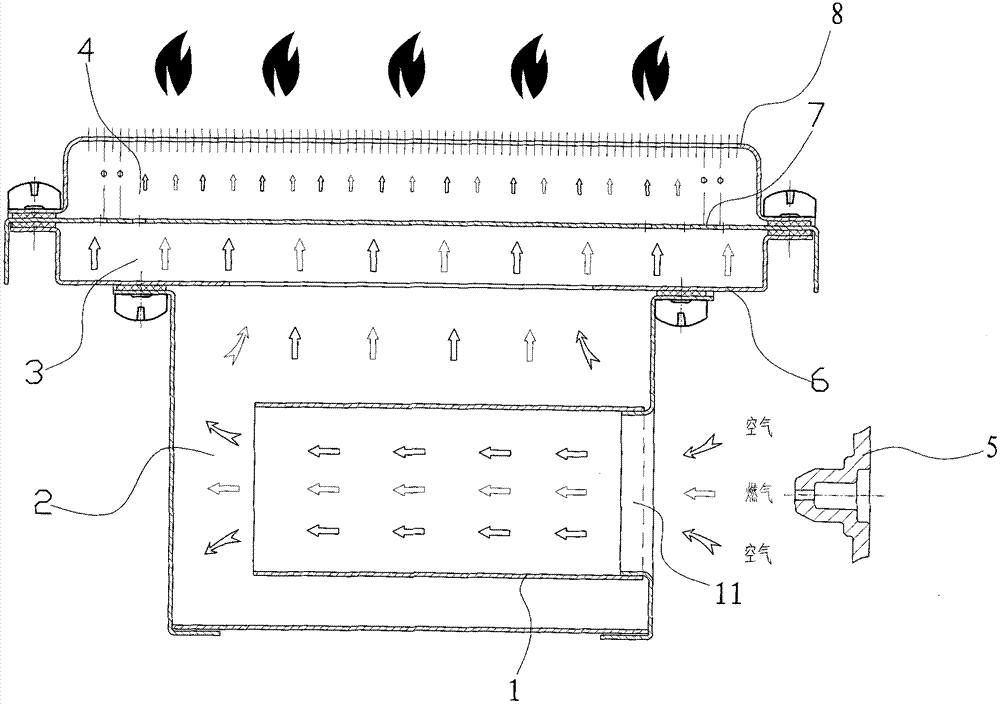

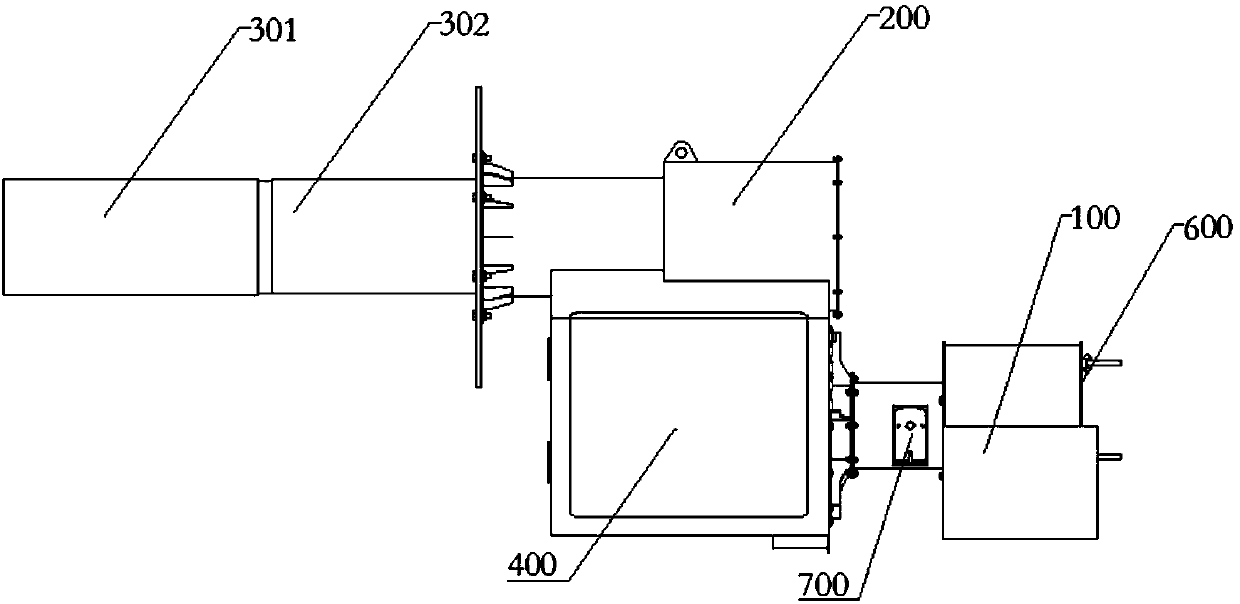

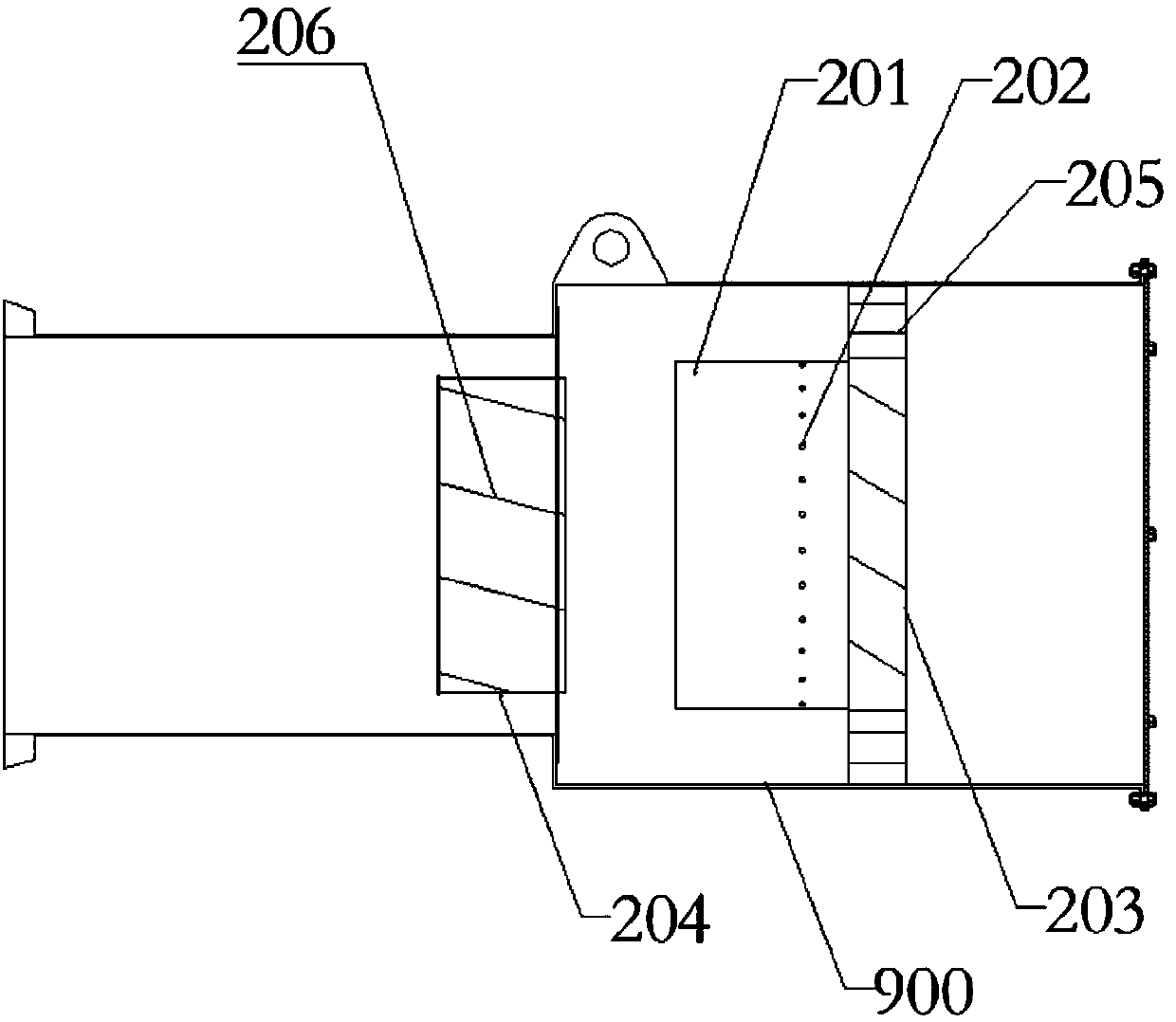

Flame vortex type cast tube annealing furnace and annealing method

PendingCN108411090AHeating evenlyUniform temperatureFurnace typesHeat treatment furnacesCold airCombustion system

The invention discloses a flame vortex type cast tube annealing furnace and an annealing method. the annealing furnace comprises an annealing furnace and an annealing furnace combustion system, wherein the annealing furnace is composed of a heating section, a heat preservation section, a fast cooling section and a slow cooling section in sequence; and the annealing furnace combustion system is mainly composed of a combustion-supporting air system, a gas supply system and an electrical control system, wherein the gas supply system mainly comprises flat flame combustors, and the flat flame combustors are uniformly distributed at the top of hearths of the heating section, the heat preservation section and the slow cooling section. Compared with the prior art, the flame vortex type cast tube annealing furnace and the annealing method have the advantages that the heating is uniform, local overheating is prevented, a backflow area is formed in the center of the flat flame caused by airflow rotation, and the effects of stabilizing flame and stirring flames are achieved, so that the temperature is uniform, and the heating is uniform; the heating speed of materials is increased, yield of the furnace is improved, and the furnace pressure is uniform, so that cold air is prevented from being sucked in; and more than 20% of fuel gas can be saved, tempering is not easy, and the performance of safety and tempering prevention is achieved.

Owner:SICHUAN CHUANJIAN PIPES

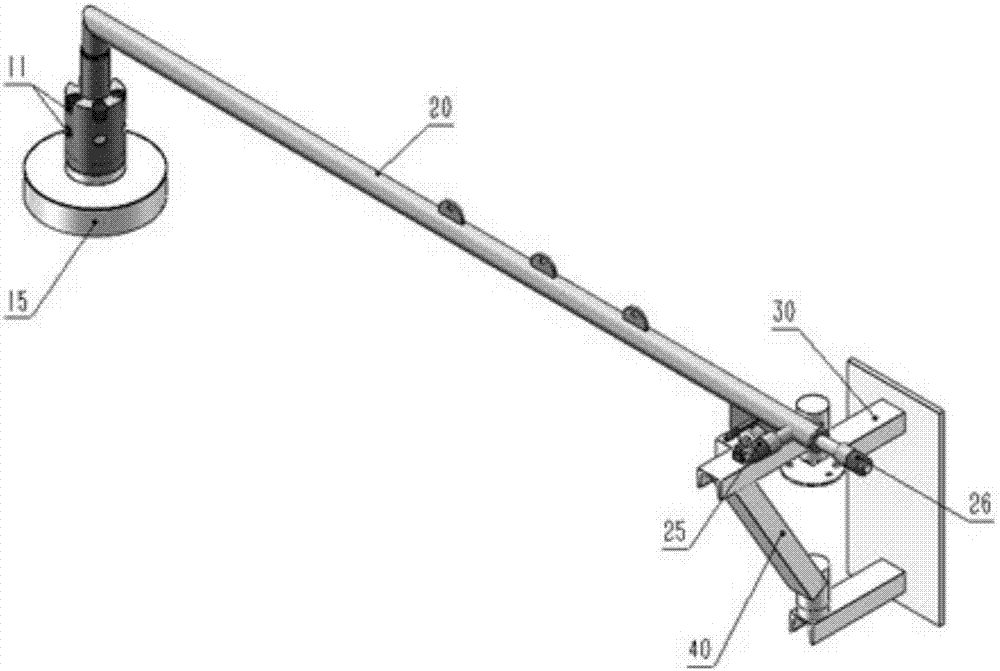

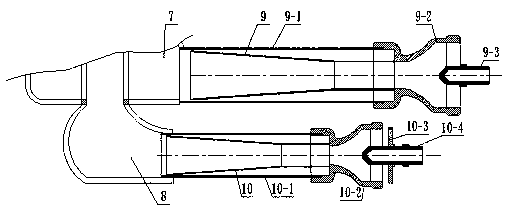

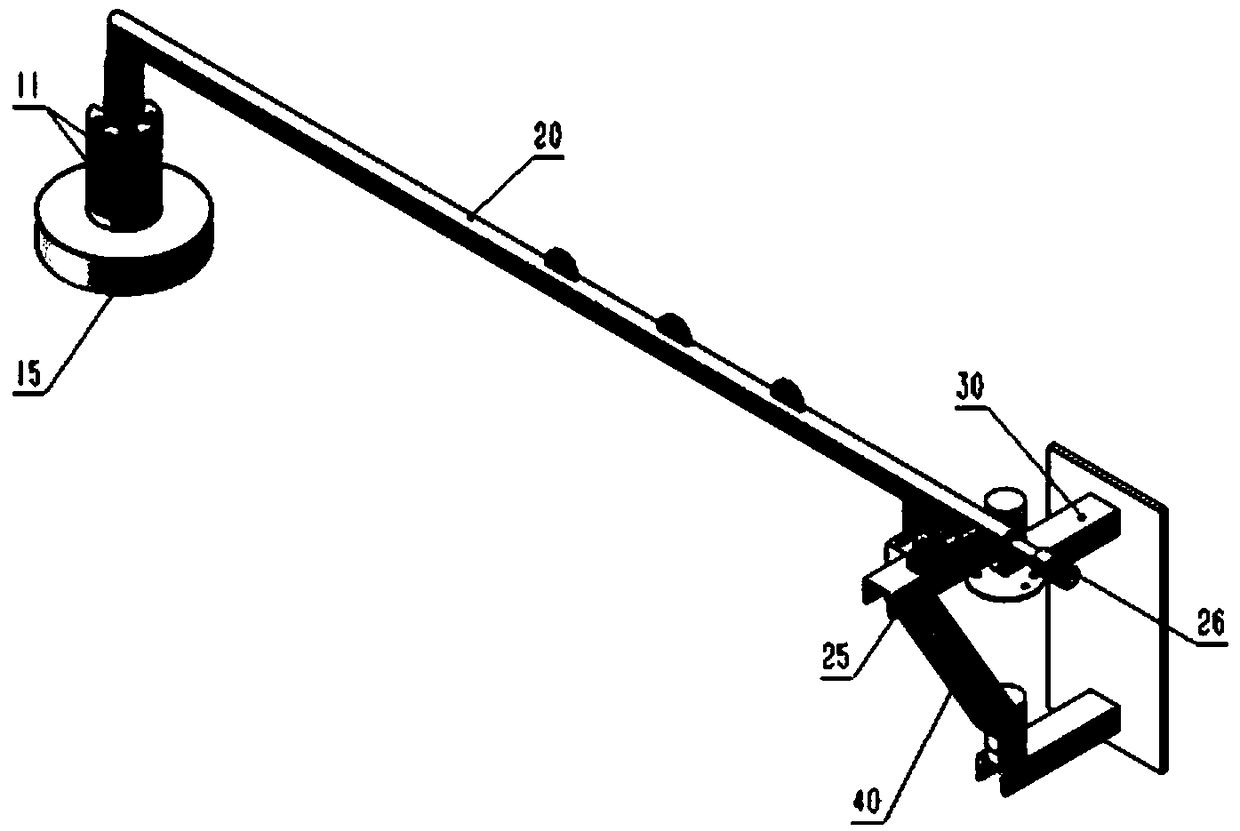

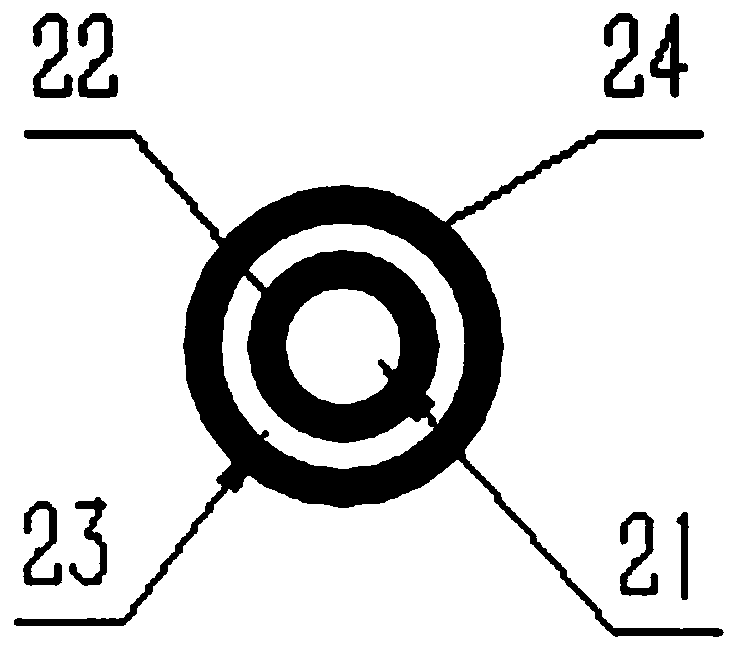

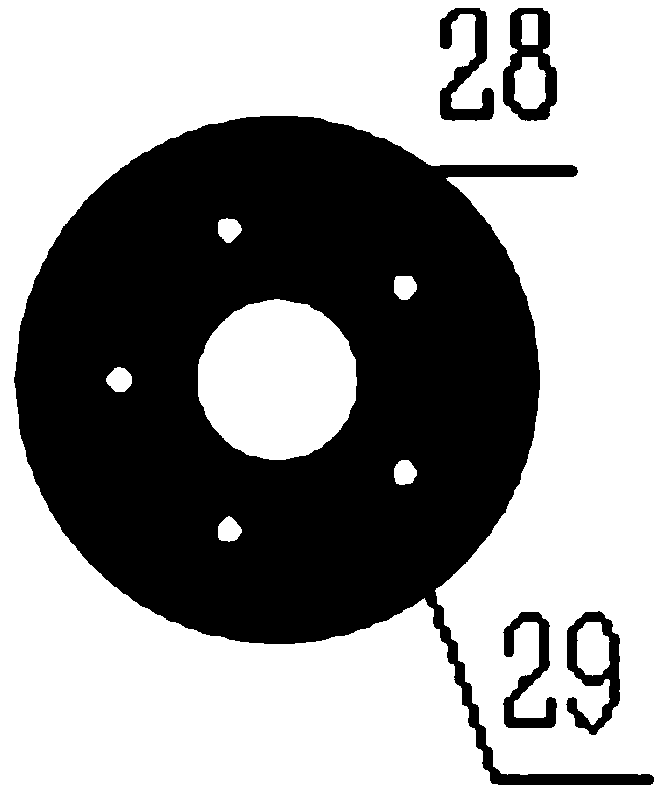

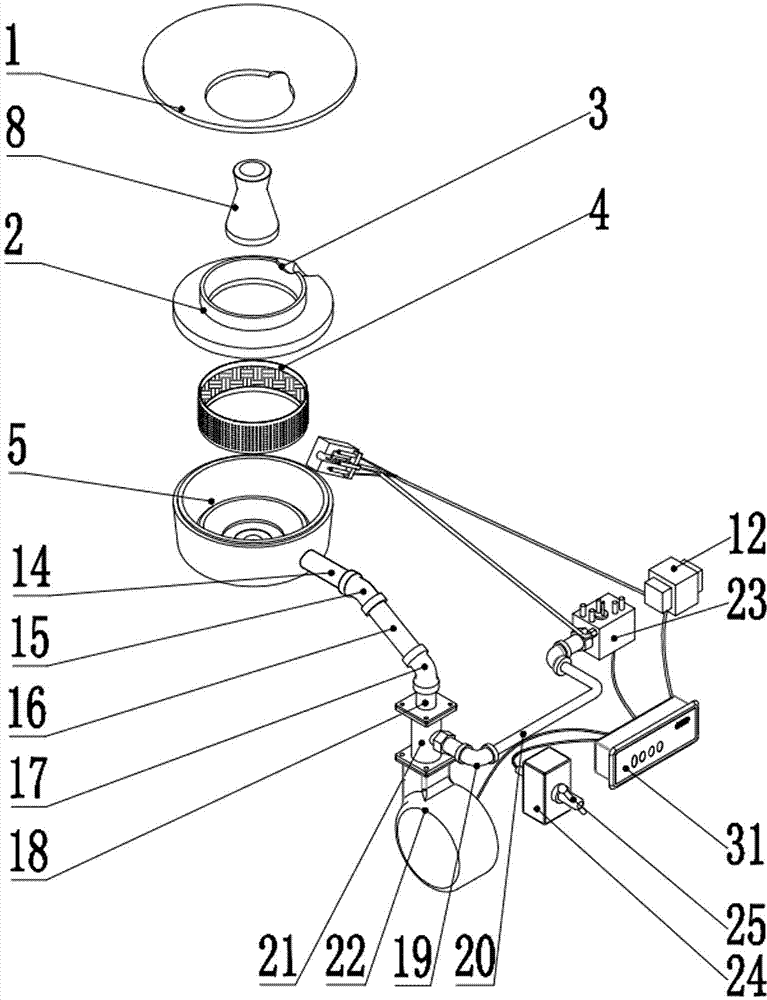

Roasting gun device

The invention discloses a roasting gun device. The roasting gun device comprises a support, a gun body and a gun head, wherein the middle part of the gun body is of a sleeve structure with an inner layer charged with fuel gas and an outer layer charged with compressed air, a bearing seat for allowing the gun body to rotate around the support is arranged on the rear part of the gun body, and a fuel gas connector and a compressed air connector are formed in the rear part of the gun body; a fuel gas-air mixing pipe and a secondary mixing and decompression pipe for supplementing air and balancing a gas pressure are arranged on the front part of the gun body; the support is used for installing and supporting the gun body and enabling the gun body to rotate and move around an axis in the horizontal direction; a main fire hole is formed in the middle of the gun head, and 18-28 auxiliary fire holes are distributed around the gun head; and the outer layer of the gun head is a heat-collecting cover. According to the roasting gun device disclosed by the invention, a fuel and air are uniformly mixed, air needed for combustion can be automatically balanced, and the temperature of the gun head can be lowered, so that the problems of poor roasting effect and unsafety of unshaped casting material products in scrap copper smelting, and anode copper casting dies are solved.

Owner:JIANGXI COPPER

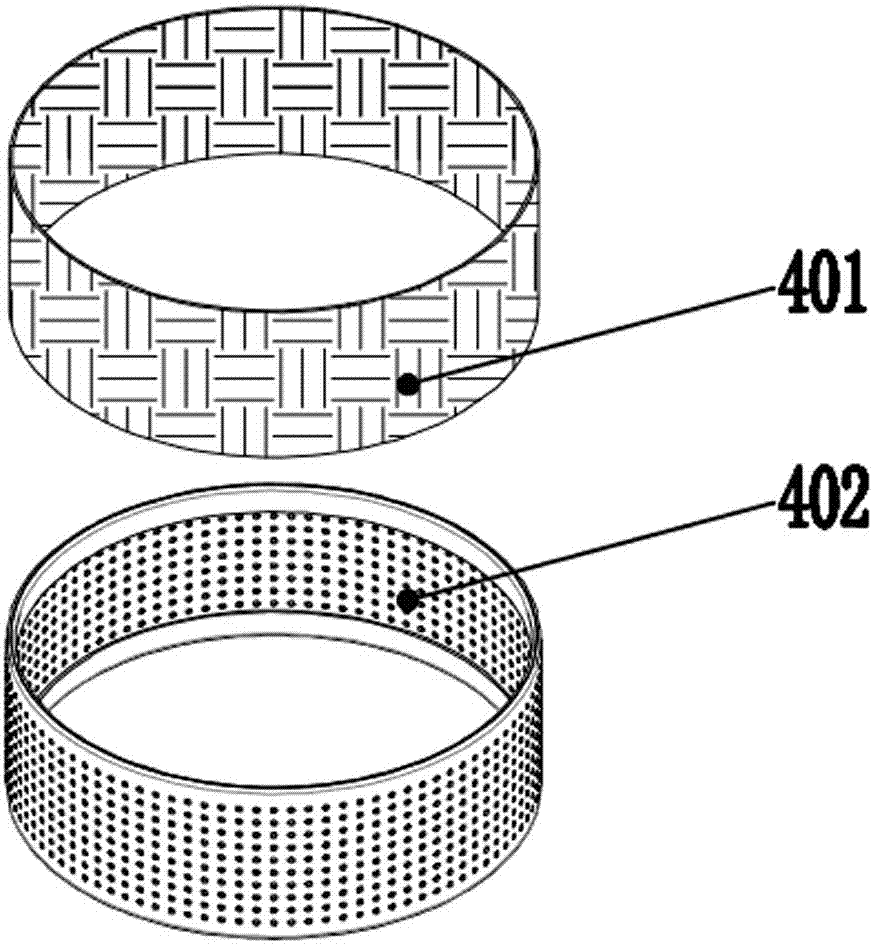

Gas premixed burner

The embodiment of the invention discloses a gas premixed burner. The gas premixed burner has a burning direction; an impeller-shaped mixer and a burner substrate are arranged in a burner main body; the impeller-shaped mixer is arranged on the upstream of the burner substrate, so that gas and air are uniformly mixed before burning; a main burning surface is arranged on the downstream of the burner substrate; the main burning surface and the burner substrate are tightly connected in a matching manner; an auxiliary flame burning surface and the main burning surface are tightly connected in the matching manner; a main flame of the main burning surface and an auxiliary flame of the auxiliary burning surface are positioned on the same plane; as the scale of the main flame is greater than that of the auxiliary flame and the air current speed of the main burning surface is greater than that of the auxiliary flame burning surface, the auxiliary flame realizes the effect of stabilizing the main flame; a burning chamber is arranged on the downstream of the main burning surface and the effect of further stabilizing the burning is realized. According to the gas premixed burner disclosed by the invention, a metal mesh is taken as the burning surface; with larger porosity, the metal mesh has low possibilities of being blocked by tiny dust in the air, tempering and floating flame; a fan has higher efficiency.

Owner:袁树月

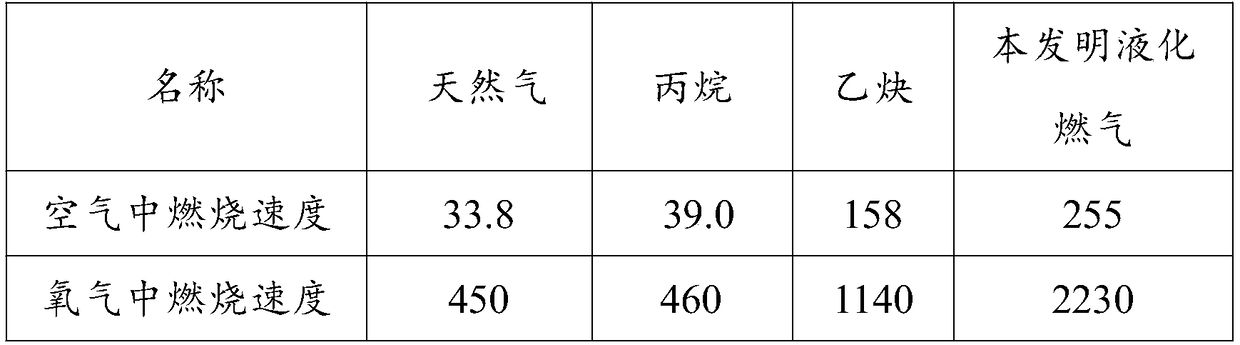

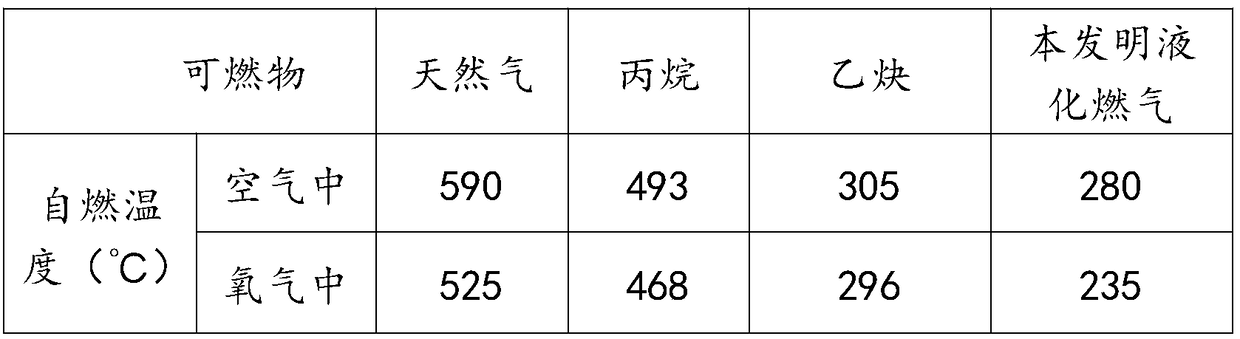

Strengthened hydrocarbon to be input into torch and burnt together with oxygen

The invention relates to a strengthened hydrocarbon to be input into a torch and burnt together with oxygen and provides an additive with compound energy efficiency of reducing the ignition point of a base stock hydrocarbon, promoting the burning rate, and increasing and gathering energy to strengthen oxidization. The additive is added to the base stock hydrocarbon so that some shortcomings of the base stock hydrocarbon in actual use can be improved and optimized; as a result, the shortcomings of not easy ignition, high oxygen consumption, low flame burning rate, low flame temperature and disperse flame heat of the base stock hydrogen during thermal cutting, processing and welding can be solved. Through actual testing, the base stock hydrocarbon basically reaches the standard of acetylene gas and even is superior to the acetylene gas in some performance aspects. In cutting quality method, adhering slag is not easy to form after cutting, and even though the adhering slag is formed, the adhering slag is also easy to clear away; the cut surface is good in degree of finish; in use, the strengthened hydrocarbon has the advantages of not easy tempering and fire suppression, no black smoke, good safety performance and the like.

Owner:陈波

Burner for outputing thick and thin premixed gas by using small fire holes and conical tubular fire holes

PendingCN110848686ANot easy to temperIncrease temperatureGaseous fuel burnerThermodynamicsKitchen utensils

The invention relates to the field of commercial kitchen utensils, in particular to a burner for outputing thick and thin premixed gas by using small fire holes and conical tubular fire holes. According to the burner for outputing the thick and thin premixed gas by using the small fire holes and the conical tubular fire holes, the small-aperture circular fire holes and the large-aperture conical tubular fire holes are used, the premixed gas with higher concentration and the premixed gas with lower concentration are simultaneously output for secondary mixing and combustion, and the premixed gaswith the higher concentration and the premixed gas with the lower concentration complement each other with missing air and fuel gas in the combustion reaction process. Two kinds of burners are combined together, two kinds of fuel gas and air supply mixing structures and two kinds of fire hole characteristics are adopted to output two thick and thin premixed gas, and the thick and thin premixed gas is subjected to secondary mixing and combustion in the combustion reaction process. The thick and thin premixed gas burner which is not prone to being tempered and does not require secondary air supply in the combustion reaction process can be provided.

Owner:浙江惠厨节能科技有限公司

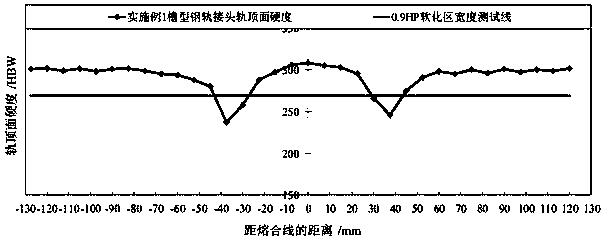

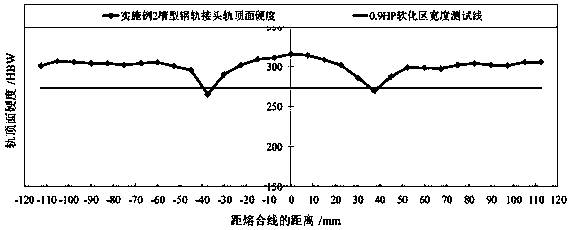

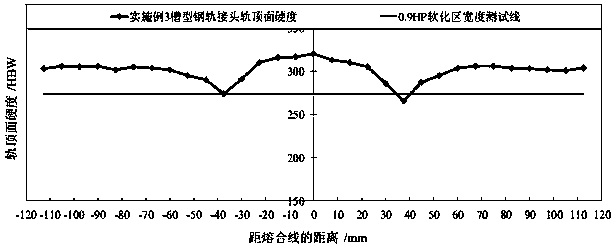

Post-welding heat treatment method for groove-shaped steel rail flash welding joint

InactiveCN110257620AGuaranteed heating effectLow costFurnace typesHeat treatment furnacesOxygenFlash welding

The invention belongs to the technical field of railway steel rail welding, and particularly relates to a post-welding heat treatment method for a groove-shaped steel rail flash welding joint. The method comprise the steps: firstly, cooling the groove-shaped steel rail welding joint obtained by welding to 50 DEG C or less, heating the welding joint to 880-920 DEG C by oxygen-liquefied petroleum gas flame and then stopping heating, immediately performing air injection cooling on rail top surface and traveling side of the welding joint through an air injection device, and stopping air injection after the center temperature of a welding seam on the rail top surface of the welding joint is reduced to 450-520 DEG C; and finally naturally cooling the welding joint to room temperature. According to the flash welding joint treated by the heat treatment method, the hardness of the rail top surface of the welding joint is matched with the hardness of steel rail base material, the joint has no abnormal structures such as Martensite and Bainite, the cost is low, meanwhile, a rail lip, a rail waist and a rail flange of the welding joint are not blown, and the parts have the characteristics of being slow in cooling speed, low in hardness, good in shaping and toughness.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Biomass boiler

InactiveCN104633631AReduce flue gas velocityNot easy to make friends withWater-tube boilersSolid fuel combustionAir preheaterCombustion system

The invention relates to a biomass boiler. The biomass boiler comprises a hearth, boiler barrels, a water cooling system, a combustion system, a coal economizer and air preheaters. The boiler barrels are arranged above the hearth and comprise the upper boiler barrel and the lower boiler barrel, the upper boiler barrel is connected with a water conveying pipe, and the lower end of a connecting pipe of the lower boiler barrel is connected with a lower header. The water cooling system comprises water cooling walls which are arranged on the two sides of the inside of the hearth and a water cooling screen which is connected to the upper portion of the inside of the hearth. The combustion system is provided with a scale-type chain grate, a feeding machine is arranged at a hearth opening in the front end of the scale-type chain grate, and air chambers, an ash discharging opening and a slag removal opening are formed below the scale-type chain grate. An ash bucket is arranged over the slag removal opening, a furnace top smoke tube arranged on the top of the hearth is connected with the coal economizer, the coal economizer is supported in a ventilating duct, and the air preheaters are connected beneath the coal economizer. A boiler smoke outlet is formed in the side portion of the tail end of the ventilating duct. The biomass boiler is low in smoke flow speed, capable of not abrading the heating surface, not prone to coking and tempering, stable and reliable to operate, and capable of guaranteeing continuous operation of production.

Owner:酒泉市汉鑫科技有限公司

Combustion improver for liquefied natural gas

The invention discloses a combustion improver for liquefied natural gas. The combustion improver comprises, by weight, 20-35 parts of tung oil, 10-25 parts of ethanol, 10-30 parts of n-butanol, 10-27 parts of cyclopentanol, 12-32 parts of ethylene glycol monobutyl ether, 5-20 parts of methyl ethyl ketone and 2-12 parts of borane tetrahydrofuran. The combustion improver has the advantages that the calorific value of the fuel gas can be increased effectively, the combustion speed of the liquefied natural gas can be increased greatly, high temperature can be obtained by combustion in oxygen, the liquefied natural gas with the combustion improver can effectively replace acetylene and be used for flame welding and cutting of metal, the firing point of fuel can be lowered, fuel can be saved, and deep application of the fuel can be achieved.

Owner:张国平

Burner

The invention relates to a burner, which comprises a gas mixing chamber for mixing gas and air, and is characterized in that: a cover plate is detachably arranged on the top of the gas mixing chamber; and a plurality of fire holes which allow flame to pass through are distributed on the cover plate at intervals. Compared with the prior art, the burner has the advantages that: the cover plate is arranged on the top of the gas mixing chamber, is provided with the fire holes and can effectively buffer the pressure of the flame jetted from jet orifices, so that floating flame is formed on the surface of the cover plate; and the whole burner is difficult to temper.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Energy-saving environment-friendly engine

InactiveCN105888846ASolve the problem of wasting a large amount of high-temperature heat energy generated by fuelSolve the problem that the temperature is difficult to exceed 700°CGas turbine plantsNon-positive displacement enginesImpellerThermal energy

The invention discloses an energy-saving environment-friendly engine. The serious internal resistance phenomenon of a traditional crankshaft engine is eliminated, and meanwhile high-temperature heat energy generated by violent combustion of fuel in a combustion chamber is utilized for generating ultra-supercritical superstrong steam power at the temperature of 600 DEG C or above. The engine is mainly composed of an impeller, a fuel gas direct injection cylinder (16), an ultra-supercritical steam injection cylinder (18), a high temperature resisting thermal radiation diversion isolating sheet or high temperature resisting flame jet flow separation plate, a two-gas combined main heating and stress applying chamber and the like. Due to the fact that the interior of the ultra-supercritical steam injection cylinder of the engine can be heated by a wide and long high-temperature thermal radiation sheet above the fuel gas direct injection cylinder, or high-temperature flames ranging from 1,000 DEG C to 2,000 DEG C below the high temperature flame jet separation plate are directly jet into the ultra-supercritical steam injection cylinder of the engine for heating, especially huge ultra-supercritical steam power larger than that of traditional crankshaft piston type engines by 10-60 times is generated, and great and large-proportion energy saving and great and large-proportion power lifting better than those of all the traditional crankshaft piston type engines are thoroughly achieved.

Owner:杨兴隆

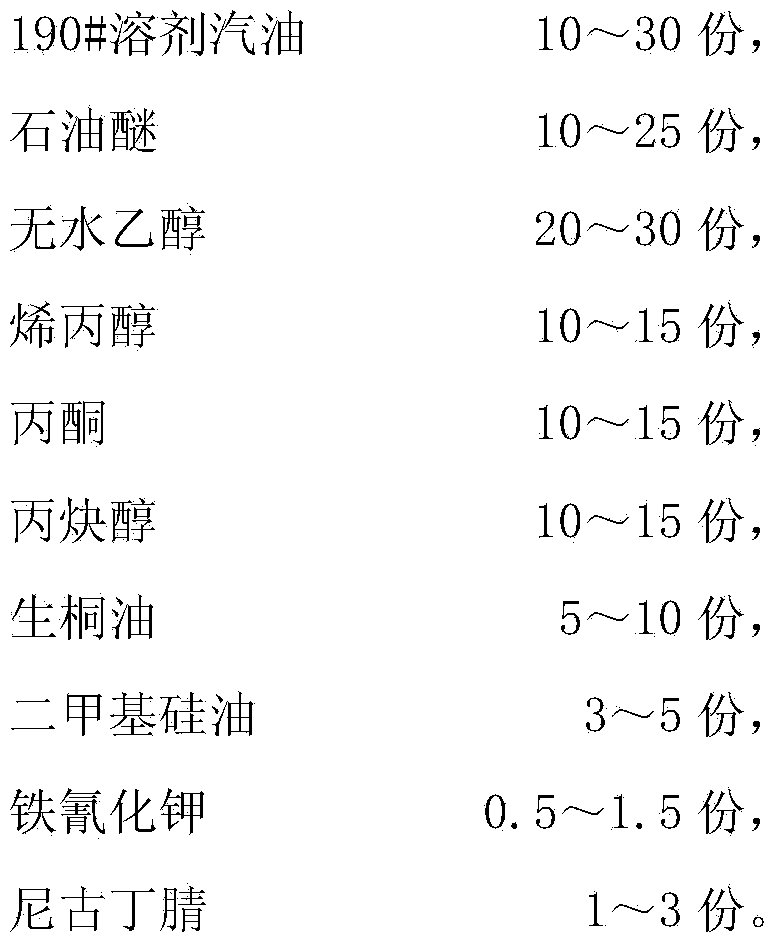

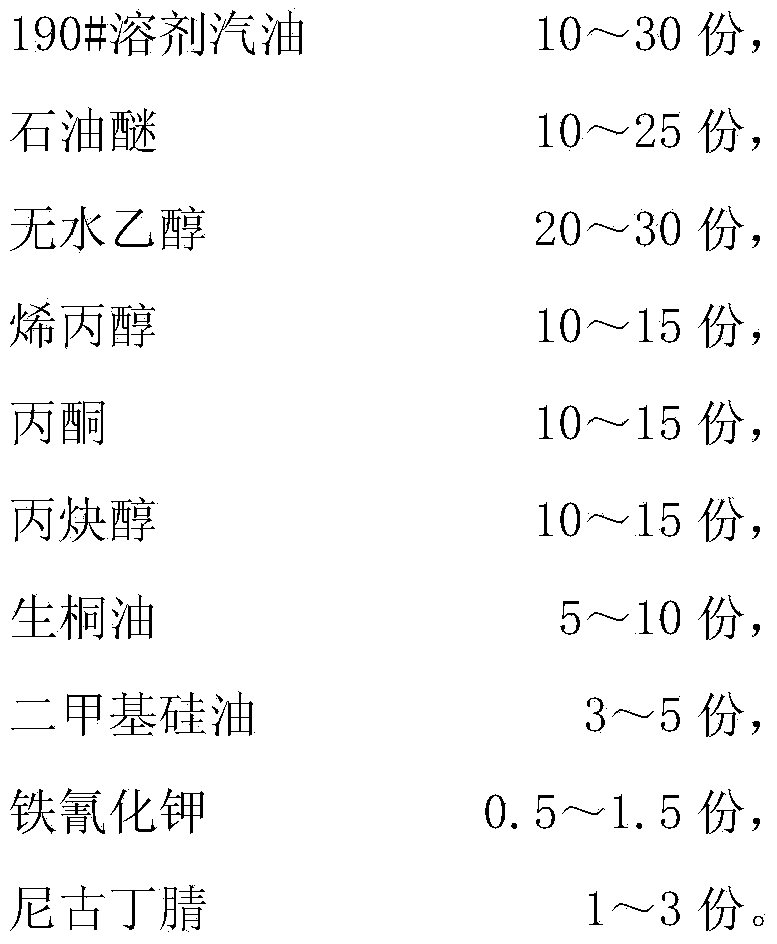

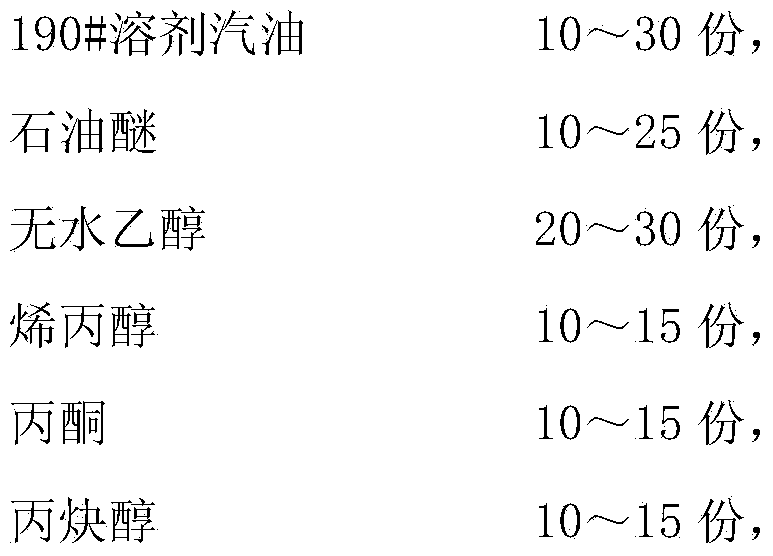

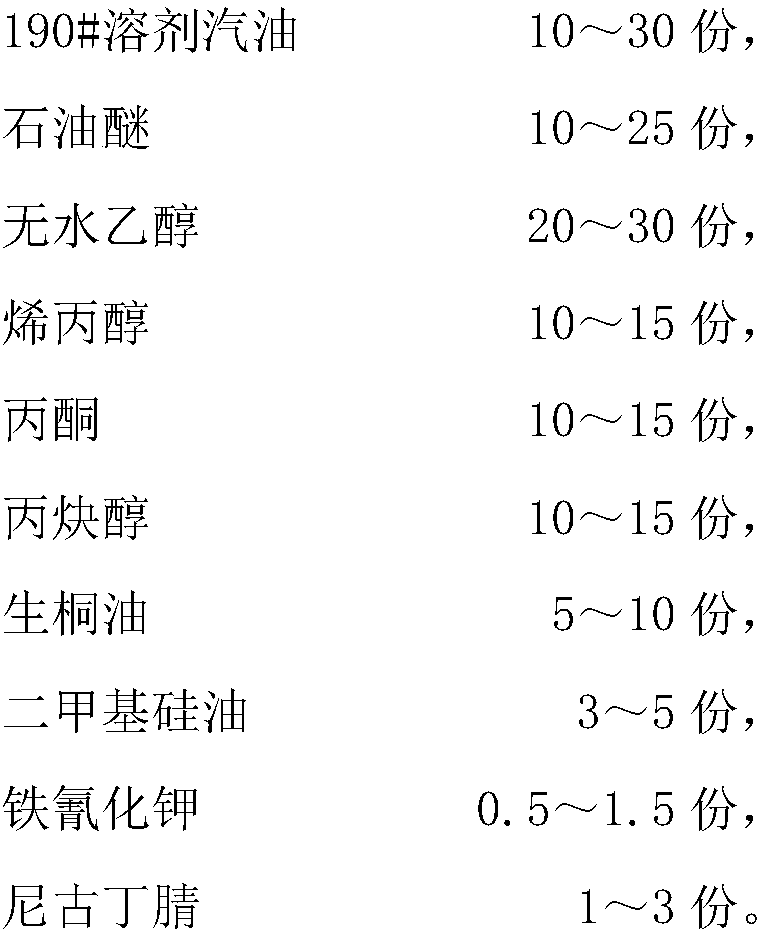

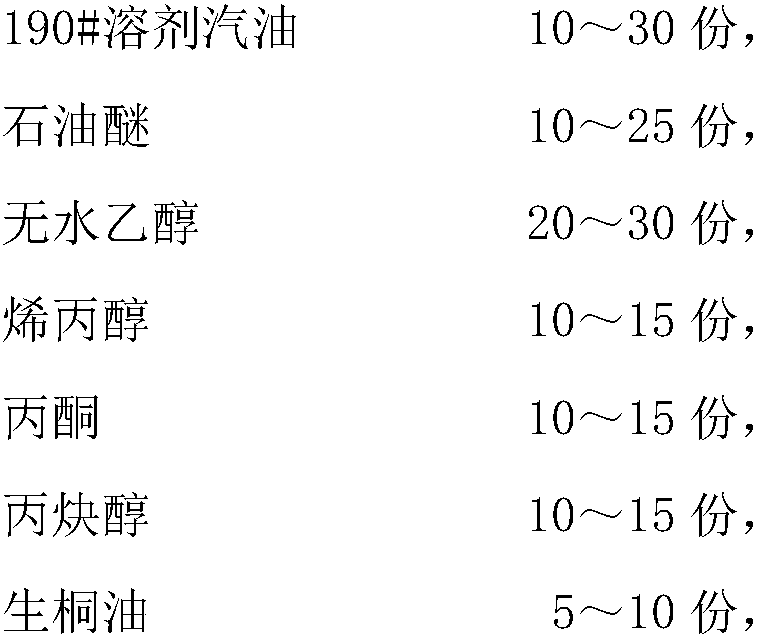

Cutting gas capable of increasing combustion heat efficiency of methane gas and preparation method of cutting gas

ActiveCN103740422AHigh calorific valueRaise the combustion temperatureGaseous fuelsFuel additivesPotassium ferricyanideSolvent

The invention provides a cutting gas capable of increasing combustion heat efficiency of a methane gas and a preparation method of the cutting gas. The cutting gas comprises a catalysis warming agent and the methane gas, wherein the catalysis warming agent comprises the following components in parts by weight: 10-30 parts of 190# solvent gasoline, 10-25 parts of petroleum ether, 20-30 parts of absolute ethyl alcohol, 10-15 parts of allyl alcohol, 10-15 parts of acetone, 10-15 parts of propargyl alcohol, 5-10 parts of raw tung oil, 3-5 parts of simethicone, 0.5-1.5 parts of potassium ferricyanide and 1-3 parts of nicotine nitrile. The invention further relates to the preparation method of the cutting gas. The cutting gas capable of increasing the combustion heat efficiency of the methane gas has the advantages of remarkable energy saving efficiency, high combustion speed, high flame temperature, high cutting level and the like. The cutting gas capable of increasing the combustion heat efficiency of the methane gas, provided by the invention is capable of saving the fuel by above 20 percent and oxygen by above 25 percent when applied to a flame welding and cutting process.

Owner:郑超

A hydrogen energy vehicle power system for purifying ambient air

ActiveCN106837529BImprove work efficiencyReduce pollutionInternal combustion piston enginesExhaust apparatusPower combinerAtmospheric pollution

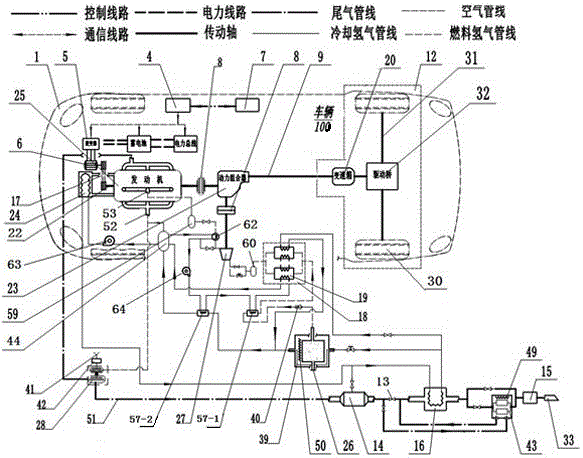

The invention relates to a hydrogen energy vehicle power system for ambient air purification. The hydrogen energy vehicle power system comprises a transmission system, a hydrogen fuel engine, a metal hydride storage tank, a hydrogen compression unit, a hydrogen stabilized tank, an inverter, a, electric-generator, an expansion machine, a storage battery and an exhaust gas disposal system. The storage battery is electrically connected with a power bus and the inverter, and the inverter is electrically connected with the electric-generator; the metal hydraulic storage tank is connected with the hydrogen fuel engine through the hydrogen compression unit and the hydrogen stabilized tank, and an exhaust outlet of the hydrogen fuel engine is connected with the exhaust gas disposal system through a turbo charger; the hydraulic fuel engine or / and the number one electric-generator is / are connected with a power combiner, the expansion machine is connected with the power combiner, and the power combiner is connected with the transmission system through a transmission shaft. By the combination of the hydrogen fuel engine with the electric-generator, operation efficiency of the hydrogen energy vehicle power system is improved; by recycling exhaust heat, atmospheric pollution is reduced, and natural environment is favorably protected.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Liquefied natural gas combustion aid

InactiveCN106147907BBurn fasterImprove heat utilizationGaseous fuelsEthyleneglycol monobutyl etherCyclopentanol

The invention discloses a combustion improver for liquefied natural gas. The combustion improver comprises, by weight, 20-35 parts of tung oil, 10-25 parts of ethanol, 10-30 parts of n-butanol, 10-27 parts of cyclopentanol, 12-32 parts of ethylene glycol monobutyl ether, 5-20 parts of methyl ethyl ketone and 2-12 parts of borane tetrahydrofuran. The combustion improver has the advantages that the calorific value of the fuel gas can be increased effectively, the combustion speed of the liquefied natural gas can be increased greatly, high temperature can be obtained by combustion in oxygen, the liquefied natural gas with the combustion improver can effectively replace acetylene and be used for flame welding and cutting of metal, the firing point of fuel can be lowered, fuel can be saved, and deep application of the fuel can be achieved.

Owner:张国平

A roasting gun device

The invention discloses a roasting gun device. The roasting gun device comprises a support, a gun body and a gun head, wherein the middle part of the gun body is of a sleeve structure with an inner layer charged with fuel gas and an outer layer charged with compressed air, a bearing seat for allowing the gun body to rotate around the support is arranged on the rear part of the gun body, and a fuel gas connector and a compressed air connector are formed in the rear part of the gun body; a fuel gas-air mixing pipe and a secondary mixing and decompression pipe for supplementing air and balancing a gas pressure are arranged on the front part of the gun body; the support is used for installing and supporting the gun body and enabling the gun body to rotate and move around an axis in the horizontal direction; a main fire hole is formed in the middle of the gun head, and 18-28 auxiliary fire holes are distributed around the gun head; and the outer layer of the gun head is a heat-collecting cover. According to the roasting gun device disclosed by the invention, a fuel and air are uniformly mixed, air needed for combustion can be automatically balanced, and the temperature of the gun head can be lowered, so that the problems of poor roasting effect and unsafety of unshaped casting material products in scrap copper smelting, and anode copper casting dies are solved.

Owner:JIANGXI COPPER

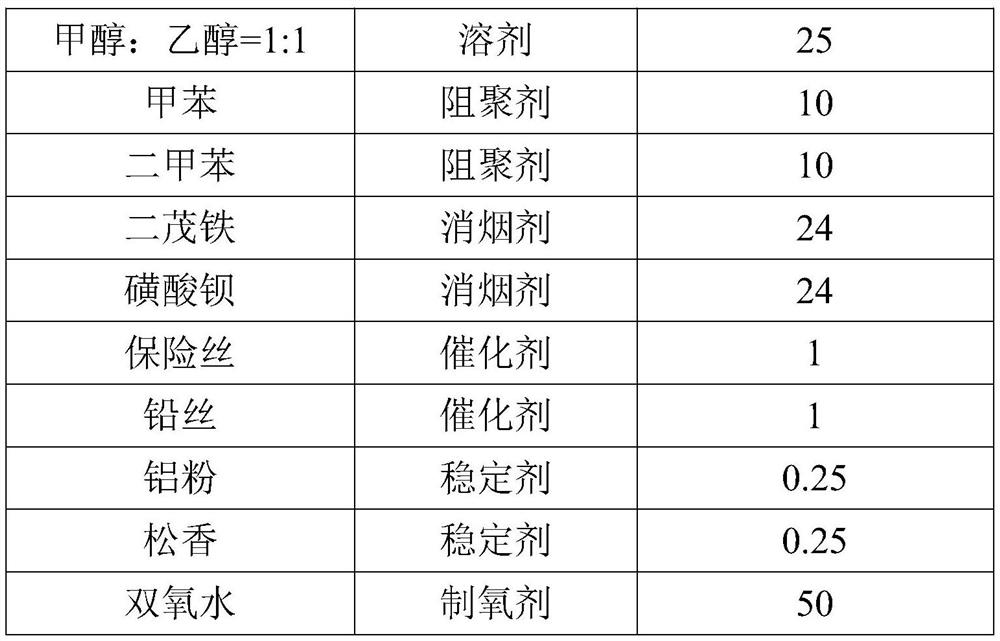

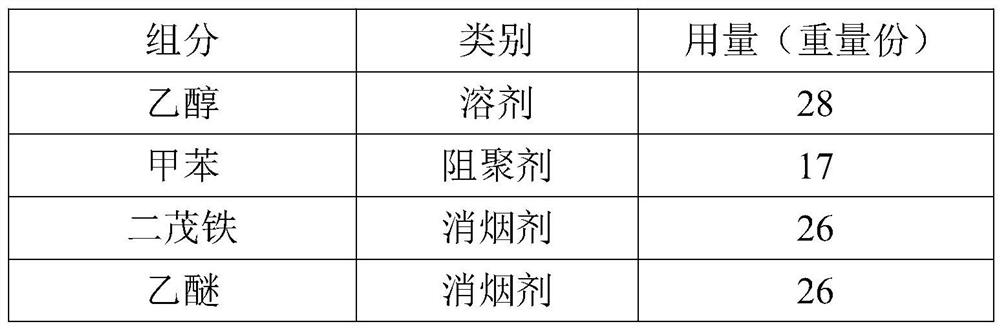

Industrial welding and cutting gas modified additive as well as preparation method and application thereof

ActiveCN114276844AAutomatically adjust the response speedEasy to cutLiquid carbonaceous fuelsGas flame welding apparatusPtru catalystProcess engineering

The invention provides an industrial welding and cutting gas modification additive. The industrial welding and cutting gas modification additive comprises the following components in parts by weight: 20-40 parts of a solvent, 10-30 parts of a polymerization inhibitor, 40-60 parts of a smoke suppressor, 0.5-4 parts of a catalyst, 0.1-1.5 parts of a stabilizer and 31-75 parts of an oxygen generating agent. According to the application of the industrial welding and cutting fuel gas modified additive, the modified additive is added into industrial fuel gas with C3 and C4 as mother liquor according to the ratio of 2-3 wt% for use. The modified additive disclosed by the invention is added into industrial fuel gases such as propane and liquefied gas, so that the gasification and activation performance of mother liquor fuel gas is improved, the wavelength and the frequency of combustion of mother liquor in oxygen are changed, and the combustion performance is improved; the flame combustion temperature of the industrial fuel gas added with the modified additive can reach about 3410 DEG C, the industrial fuel gas is superior to acetylene in the aspects of temperature, heat value, cutting effect, environmental protection, energy conservation, safety cost and the like, the cutting and welding performance of the industrial fuel gas reaches or exceeds that of acetylene gas, and the industrial fuel gas can completely replace acetylene to complete cutting and welding of metal.

Owner:HEBEI XINDA IRON & STEEL GRP CO LTD

Industrial welding and cutting gas prepared by refining biogas

ActiveCN102585944BHigh flame temperatureImprove solubilityGaseous fuelsWaste based fuelPtru catalystP-tert-Butylphenol

The invention relates to an industrial welding and cutting gas prepared by refining biogas. The biogas is taken as a main fuel, and a multifunctional catalyst is added into the biogas in a volume ratio of 15:100,000 to form the industrial welding and cutting gas, wherein the multifunctional catalyst mainly comprises the following components in part by mass: 20 to 25 parts of No.200 solvent gasoline, 15 to 20 parts of hexahydrotoluene, 10 to 15 parts of butyl acetate, 8 to 10 parts of glycol dimethyl ether, 6 to 12 parts of methyl ethyl ketone, 5 to 18 parts of n-butyl cyclohexane, 5 to 15 parts of n-butyl acetate, 6 to 12 parts of p-tert-Butylphenol and 4 to 6 parts of organic boride. The multifunctional catalyst and the biogas are matched, so that the dissolubility and dispersity of various fuels are improved, the fuels well dissolve and adsorb the methane gas, the quality of the fuels is improved, the flame temperature of the methane combusted in oxygen is improved to reach the combustion temperature of acetylene gas, and the aim of replacing the acetylene gas is fulfilled.

Owner:WUXI RUNNENG IND TECH

Cutting gas capable of improving combustion thermal efficiency of methane gas and preparation method thereof

ActiveCN103740422BHigh calorific valueRaise the combustion temperatureGaseous fuelsFuel additivesPotassium ferricyanideSolvent

The invention provides a cutting gas capable of increasing combustion heat efficiency of a methane gas and a preparation method of the cutting gas. The cutting gas comprises a catalysis warming agent and the methane gas, wherein the catalysis warming agent comprises the following components in parts by weight: 10-30 parts of 190# solvent gasoline, 10-25 parts of petroleum ether, 20-30 parts of absolute ethyl alcohol, 10-15 parts of allyl alcohol, 10-15 parts of acetone, 10-15 parts of propargyl alcohol, 5-10 parts of raw tung oil, 3-5 parts of simethicone, 0.5-1.5 parts of potassium ferricyanide and 1-3 parts of nicotine nitrile. The invention further relates to the preparation method of the cutting gas. The cutting gas capable of increasing the combustion heat efficiency of the methane gas has the advantages of remarkable energy saving efficiency, high combustion speed, high flame temperature, high cutting level and the like. The cutting gas capable of increasing the combustion heat efficiency of the methane gas, provided by the invention is capable of saving the fuel by above 20 percent and oxygen by above 25 percent when applied to a flame welding and cutting process.

Owner:郑超

An enhanced hydrocarbon fed into the torch and mixed with oxygen for combustion

The invention relates to a strengthened hydrocarbon to be input into a torch and burnt together with oxygen and provides an additive with compound energy efficiency of reducing the ignition point of a base stock hydrocarbon, promoting the burning rate, and increasing and gathering energy to strengthen oxidization. The additive is added to the base stock hydrocarbon so that some shortcomings of the base stock hydrocarbon in actual use can be improved and optimized; as a result, the shortcomings of not easy ignition, high oxygen consumption, low flame burning rate, low flame temperature and disperse flame heat of the base stock hydrogen during thermal cutting, processing and welding can be solved. Through actual testing, the base stock hydrocarbon basically reaches the standard of acetylene gas and even is superior to the acetylene gas in some performance aspects. In cutting quality method, adhering slag is not easy to form after cutting, and even though the adhering slag is formed, the adhering slag is also easy to clear away; the cut surface is good in degree of finish; in use, the strengthened hydrocarbon has the advantages of not easy tempering and fire suppression, no black smoke, good safety performance and the like.

Owner:陈波

An intelligent anti-corrosion metal fiber surface burner

ActiveCN102777903BImprove work efficiencyChange the vulnerable conditionGaseous fuel burnerHybrid systemCombustor

The invention relates to an intelligent and anti-corrosive type metal fiber surface burner, comprising a burner head, a separated type long-open-fire automatic ignition device, a gas-air mixing system and an intelligent control module, wherein the separated type long-open-fire automatic ignition device is arranged at one side of the burner head and is used for igniting the burner head; the gas-air mixing system is connected with the burner head and is used for conveying air-gas mixing gas needed by burning for the burner head; the intelligent control module is connected with the separated type long-open-fire automatic ignition device and is used for controlling the ignition of the separated type long-open-fire automatic ignition device; and the intelligent control module is connected with the gas-air mixing system and is used for controlling and adjusting the flow of air-gas mixing gas conveyed by the gas-air mixing system. The intelligent and anti-corrosive type metal fiber surface burner has the advantages that the corrosion problem of soup and juice and the like is solved, the maintenance cost is reduced, the emission is low, the efficiency is high and the intelligent electrodeless-load adjustment can be realized.

Owner:YANTAI ZHONGDE ENVIRONMENTAL PROTECTION EQUIPTECH

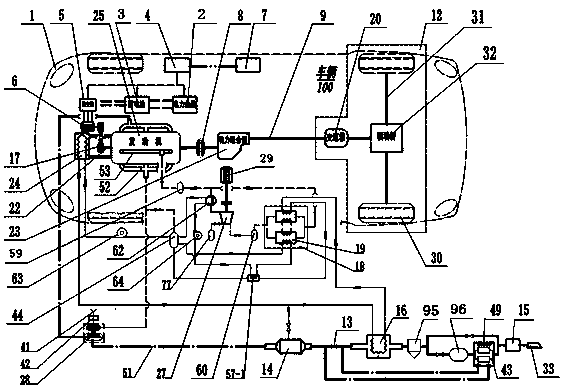

A high-efficiency hydrogen energy vehicle power system for purifying ambient air

ActiveCN106915235BReduce consumptionIncrease motivationHybrid vehiclesInternal combustion piston enginesPower combinerHigh pressure

The invention relates to an efficient hydrogen energy vehicle power system with an ambient air purifying function. The efficient hydrogen energy vehicle power system comprises a drive system, a gas turbine, a high pressure hydrogen storage tank, a hydrogen compression unit, a hydrogen gas surge tank, an inverter, an electric-power generator, an expander, a storage battery and an exhaust gas treating and discharging system. The high pressure hydrogen storage tank is connected to an inlet of the expander, one path of an outlet of the expander is connected to a hydrogen inlet through a cold capacity recovery device and the hydrogen gas surge tank, and the other path is connected to the inlet of the expander through a hydrogen compression unit and an intermediate tank. A power combiner is connected with the gas turbine and / or the electric-power generator, according to the technical scheme, the gas turbine is replaced with a hydrogen fuel engine, and the power combiner is connected with the drive system through a drive shaft. According to the efficient hydrogen energy vehicle power system with the ambient air purifying function, the gas turbine is combined with the electric-power generator, so that work efficiency of the hydrogen energy vehicle power system is improved. By recycling of exhaust gas heat, air pollution is reduced, and the natural environment can be protected easily.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

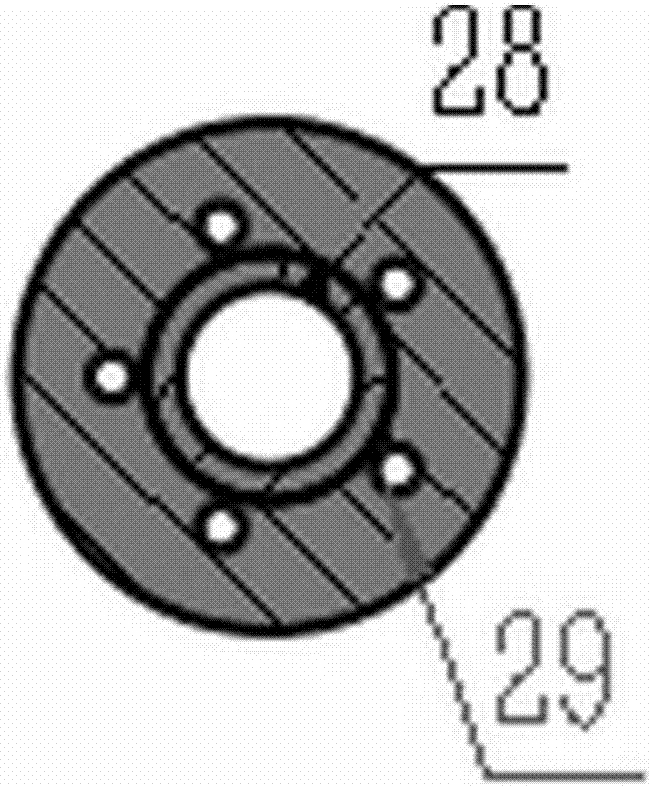

Fully premixed metal fiber burner and boiler using the burner

ActiveCN106016261BEvenly dispersedWell mixedFuel supply regulationLiquid fuel feeder/distributionCombustorBoiler furnace

The invention belongs to the technical field of combustion equipment, and relates to a full-premix type metal fiber combustor and a boiler adopting the combustor. The full-premix type metal fiber combustor comprises a draught fan, an air mixing unit and a combustion head. The draught fan is connected with the air mixing unit and used for providing air needed for combustion. The air mixing unit is connected with the combustion head and used for conducting mixing and conveying needed air and fuel gas mixed gas to the combustion head. The air mixing unit comprises an air mixing pipe and air mixing discs. A plurality of sets of through holes are formed in the side wall of the air mixing pipe in the circumferential direction. The first air mixing disc and the second air mixing disc are sequentially arranged in the gas flow direction. The air mixing pipe is arranged between the first air mixing disc and the second air mixing disc, and the first air mixing disc abuts against the air mixing pipe. According to the combustor, air and fuel gas are fully mixed, combustion is sufficient, nitrogen oxide emission is low, and high efficiency and energy saving are achieved. Meanwhile, the size of a boiler furnace of the boiler is greatly reduced, and the interior of the boiler furnace is heated evenly.

Owner:中科蓝创节能环保设备(天津)有限公司

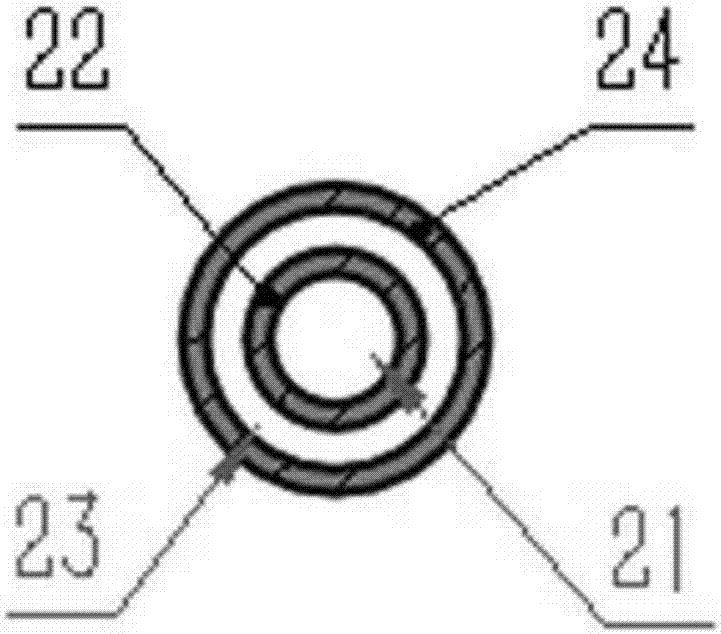

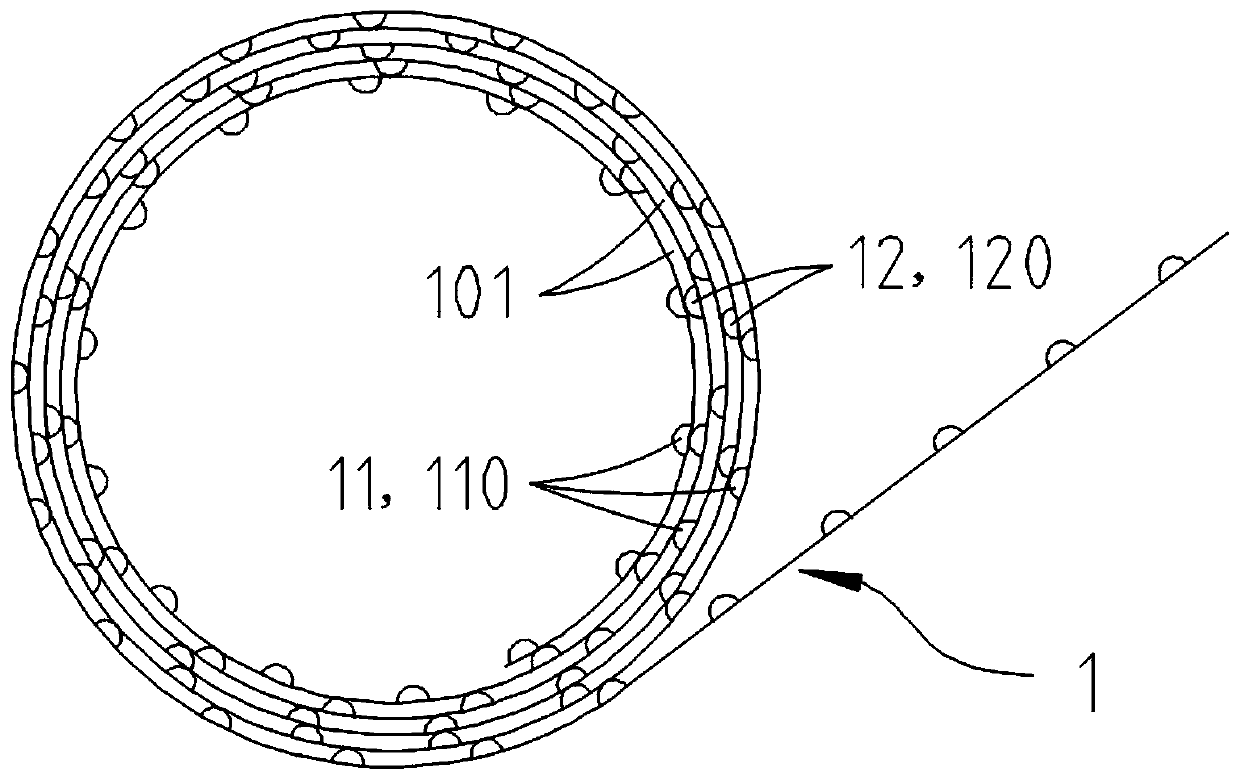

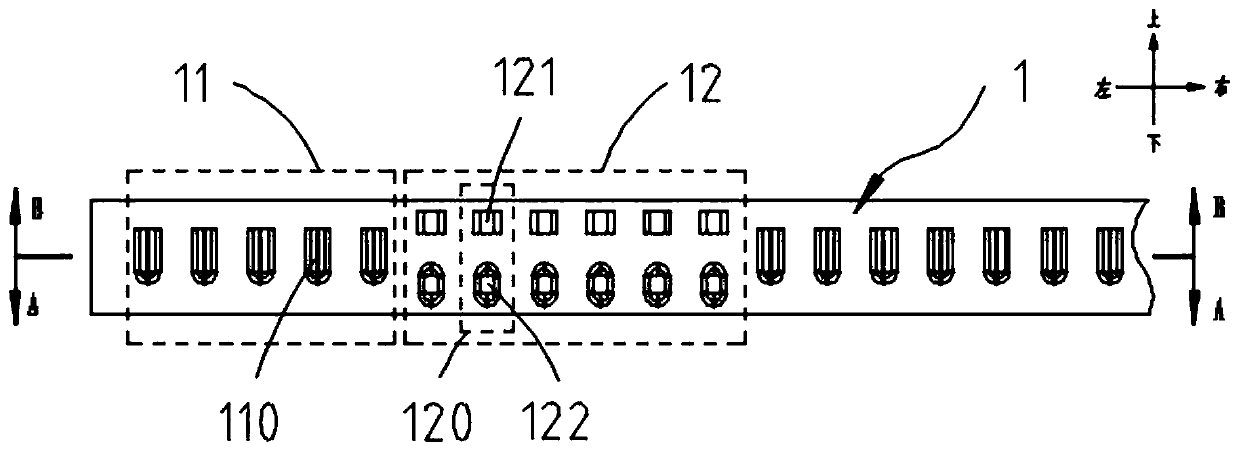

Metal honeycomb heating element for gas stove

PendingCN110440326AReduce porosityHigh speedDomestic stoves or rangesCooking fumes removalMetal stripsPorosity

The invention discloses a metal honeycomb heating element for a gas stove. The metal honeycomb heating element for the gas stove at least comprises a metal strip, a boss set I and a boss set II are alternatively arranged on the metal strip, the metal strip is coiled to form a honeycomb heating element body with a plurality of coil rings, the boss set I and the boss set II are arranged on any two adjacent coil rings respectively, and holes for gas to pass are formed between adjacent coil rings. The boss set I and the boss set II comprise a plurality of bosses, the lower ends of the bosses are sealed, and openings are formed in the upper ends of the bosses. According to the metal honeycomb heating element for the gas stove , the the porosity of the lower end of the honeycomb body is low, gascan pass through the lower end of the honeycomb heating element body with a higher speed, the lower end of the honeycomb heating element body can be better cooled, and thus the purposes that flames are prevented from spreading to the lower end of the honeycomb heating element body, the burning stability is high, and backfire is not likely to occur are achieved; and besides, the porosity of the upper end of the honeycomb heating element body is high, it is beneficial to efficient burning of gas, the heating speed is high, and meanwhile it is beneficial to discharging of burning tail gas.

Owner:VATTI CORP LTD

Energy-containing combustion-supporting catalyst and application thereof

InactiveCN102585936BImprove thermal efficiencyImprove heat utilizationGaseous fuelsLiquid carbonaceous fuelsBorideAlkane

The invention relates to an energy-containing combustion-supporting catalyst which mainly is composed of the following components by weight: 25-28 parts of fusel oil, 14-18 parts of ethanol, 16-20 parts of tetralin, 14-16 parts of cyclopentanol, 18-22 parts of crotonic aldehyde, 1-2 parts of 2-pyrrolidone, 1.5-3 parts of nano rare earth oxide, and 2-3 parts of energy-containing cage-type boride or derivates of the boride. The energy-containing combustion-supporting catalyst can be applied to liquid or gas alkane fuel to form an energy-containing composite fuel so as to promote the thermal efficiency of the fuel, and can effectively replace acetylene to be used for metal flame welding cutting so as to improve the heat utilization rate of gas boilers and kilns. The energy-containing combustion-supporting catalyst is obvious in energy-saving efficiency, and saves fuel by more than 30 percent and saves oxygen by more than 20 percent in the process of metal flame welding cutting. Furthermore, compared with acetylene, the energy-containing combustion-supporting catalyst is safe in use, and is unlikely to cause tempering, and is safe and reliable in use.

Owner:栗伟鹤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com