An intelligent anti-corrosion metal fiber surface burner

A technology of surface combustion and metal fiber, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of inaccurate artificial flame adjustment, uneven gas mixing, poor combustion effect, etc., to improve kitchen work efficiency, Improved thermal efficiency and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

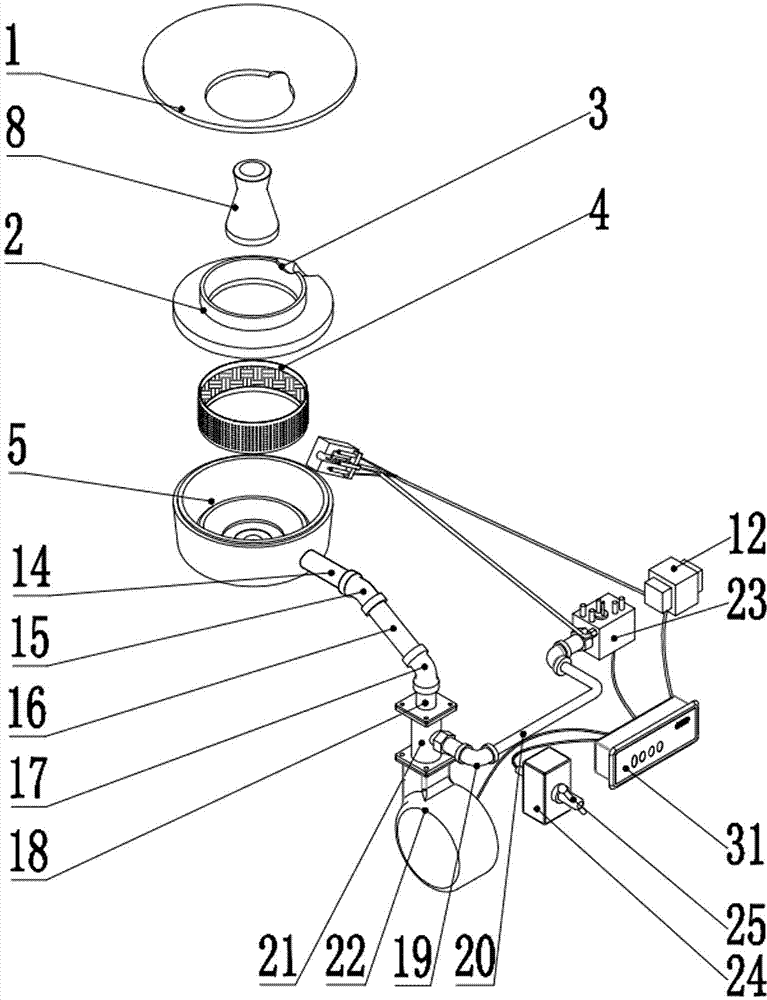

[0035] Such as Figure 1 to Figure 5 As shown, an intelligent anti-corrosion metal fiber surface burner, which includes a burner head, a separate permanent flame automatic ignition device, a gas-air mixing system and an intelligent control module,

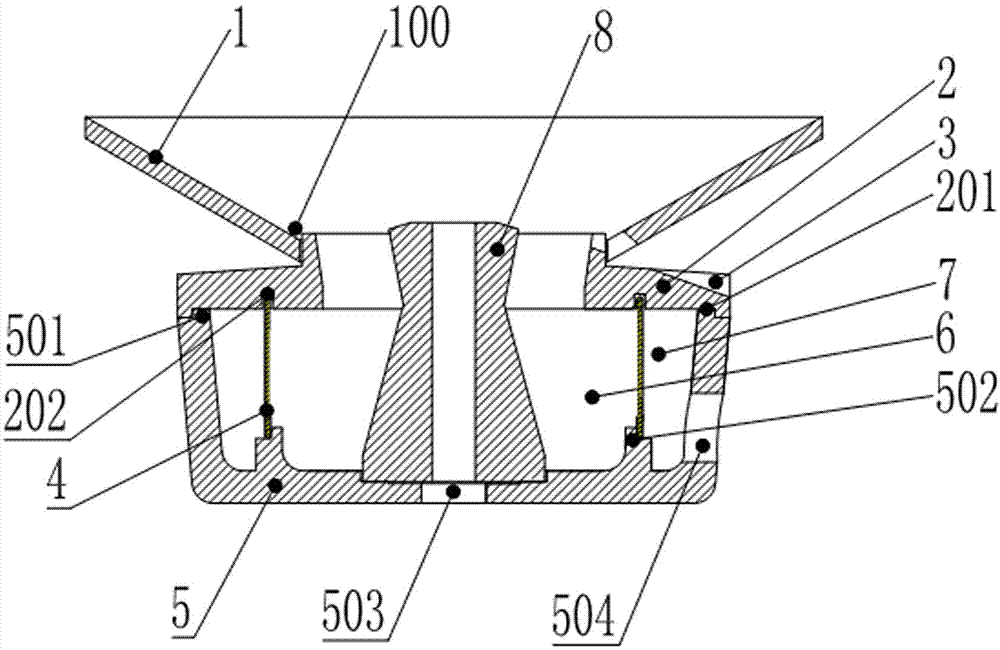

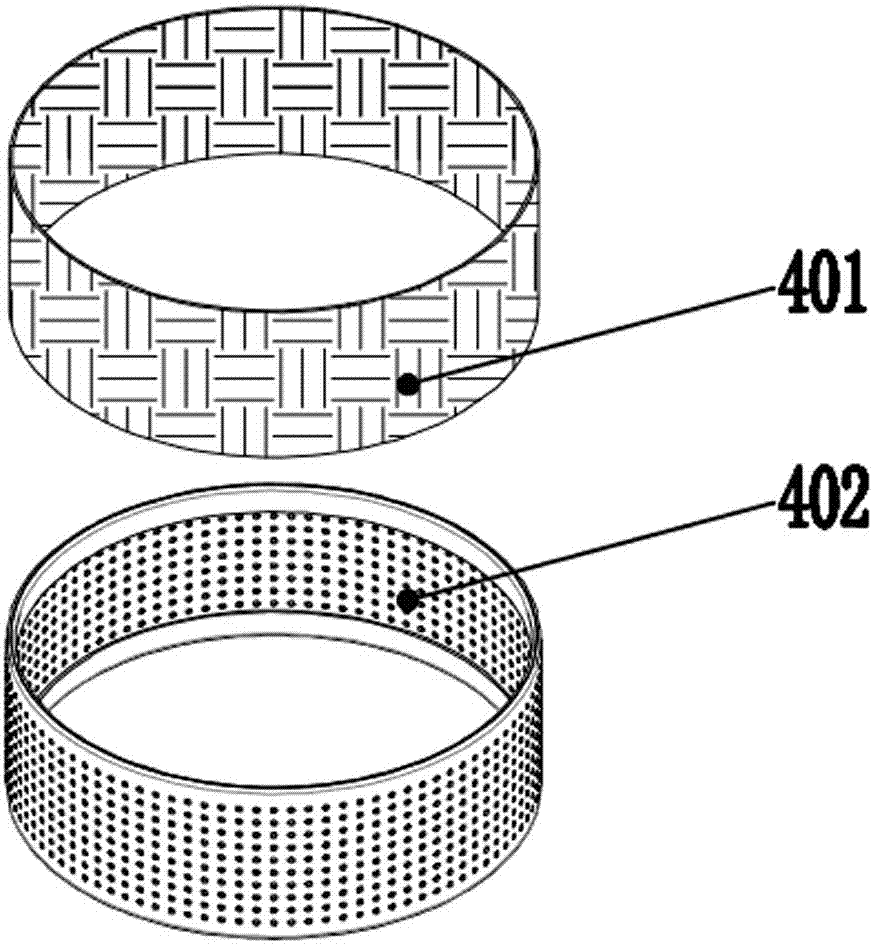

[0036]The burner head includes a heat-reflecting cone 1, an upper cover 2, a fitted surface combustion component 4, a base 5 and a flow guide cone 8, and the bottom of the upper cover 2 is provided with two concentric first grooves 201 , the second groove 202, the top of the base 5 is provided with a first protrusion 501 matching the first groove 201, the bottom is provided with a second protrusion 502 corresponding to the position of the second groove 202, the first gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com