Flame vortex type cast tube annealing furnace and annealing method

An annealing furnace and scroll technology, which is applied to the flame scroll annealing furnace and its annealing field, can solve the problems that the quality of the pipes cannot meet the requirements, environmental protection requirements, and uneven heating of the pipes, so as to prevent cold wind Inhalation, fast heating speed, uniform pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

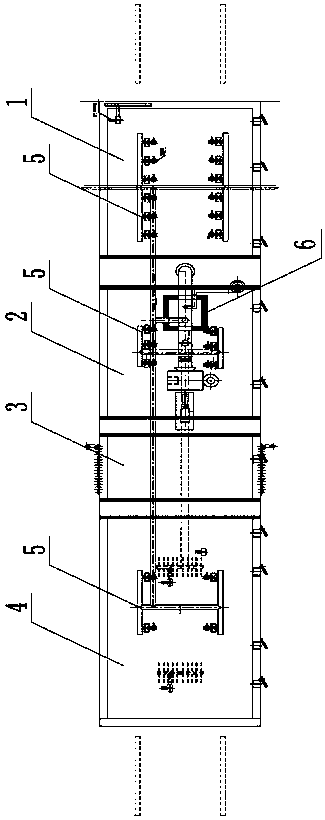

[0030] Embodiment 1: see figure 1 , a flame vortex type cast tube annealing furnace, comprising an annealing furnace and an annealing furnace combustion system, characterized in that: the annealing furnace is sequentially composed of a heating section 1, a heat preservation section 2, a fast cooling section 3, and a slow cooling section 4 The combustion system of the annealing furnace is mainly composed of a combustion-supporting air system 6, a gas supply system and an electrical control system. The gas supply system mainly includes a flat flame burner 5, and the flat flame burner 5 is evenly distributed in the heating section 1, The top of the heat preservation section 2 and the slow cooling section 4 furnace. Different from the traditional straight-flame burner that burns from the side, what it sprays out is not a straight flame, but a disc-shaped thin-layer flame that is close to the furnace wall or furnace roof and spreads evenly around. A flat airflow can be formed by u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com