Post-welding heat treatment method for groove-shaped steel rail flash welding joint

A technology for post-weld heat treatment and grooved rails, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems affecting train driving safety, wear at parts with low hardness, low hardness of welded joints, etc., to achieve good shape and Toughness, increased strength and hardness, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

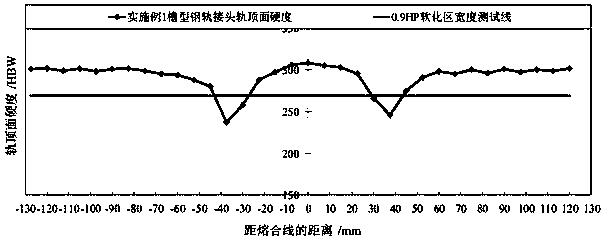

Embodiment 1

[0030]When the channel rail flash welding joint is air-cooled to 40°C, the oxygen-liquefied petroleum gas flame is used to heat the channel rail welding joint. h, the heating time is 340s; when the temperature of the top surface of the welded joint rail reaches 910°C, stop heating, and then use the air blowing device to cool the top surface of the welded joint rail and the working side, and the distance between the air spray port and the top surface of the welded joint rail is 40mm. The wind pressure is 0.20MPa; when the temperature of the top surface of the rail is air-cooled to the final cooling temperature of 500°C, stop the air spray cooling, and then the welded joints are naturally cooled to room temperature; the welded joints of the channel rails that are post-weld heat treated refer to CECS429: According to the 2016 standard, after the sample is taken and processed, it is corroded with 3% nitric acid alcohol after processing, and the test point position is marked on the ...

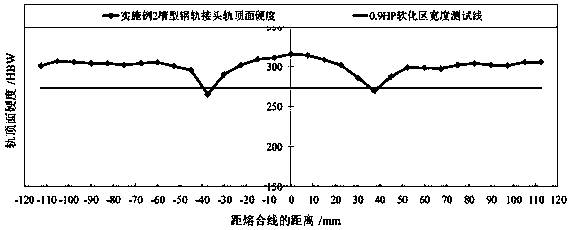

Embodiment 2

[0033] When the channel rail flash welding joint is air-cooled to 32°C, the oxygen-liquefied petroleum gas flame is used to heat the channel rail welding joint. h, the heating time is 330s; when the temperature of the top surface of the welded joint rail reaches 900°C, stop heating, and then use the air blowing device to spray air on the top surface of the welded joint rail and the working side to cool it. The blowing air pressure is 0.20MPa; when the temperature of the top surface of the rail is air-cooled to the final cooling temperature of 480°C, stop the blowing air cooling, and then the welded joints are naturally cooled to room temperature; the post-weld heat-treated grooved rail welded joints shall refer to CECS429 :2016 standard, after the sample is taken and processed, it is corroded with 3% nitric acid alcohol after the processing is completed, the test point position is marked on the top surface of the welded joint rail and the hardness of the top surface of the rail...

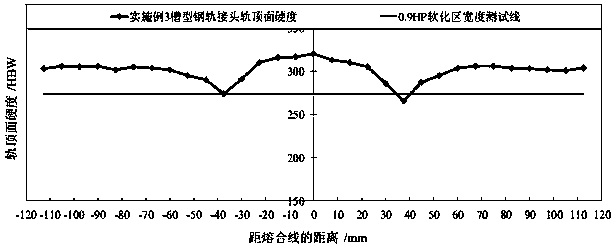

Embodiment 3

[0036] When the channel rail flash welding joint is air-cooled to 30°C, the oxygen-liquefied petroleum gas flame is used to heat the channel rail welding joint. h, the heating time is 352s; when the temperature of the top surface of the welded joint rail reaches 920°C, stop heating, and then use the air blowing device to spray air on the top surface of the welded joint rail and the working side to cool it. The blowing air pressure is 0.18MPa; when the temperature of the top surface of the rail is air-cooled to the final cooling temperature of 460°C, stop the blowing air cooling, and then the rail joints are naturally cooled to room temperature; the welded joints of the grooved rails after post-welding heat treatment refer to CECS429 :2016 standard, after the sample is taken and processed, it is corroded with 3% nitric acid alcohol after the processing is completed, the test point position is marked on the top surface of the welded joint rail and the hardness of the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com