Cutting gas capable of improving combustion thermal efficiency of methane gas and preparation method thereof

A technology of methane gas and thermal efficiency, applied in the direction of gas fuel, fuel, fuel additives, etc., can solve the problems of unfavorable industrial application, increased use cost, low efficacy, etc., to achieve enhanced reducibility, safe and reliable use, and fast burning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

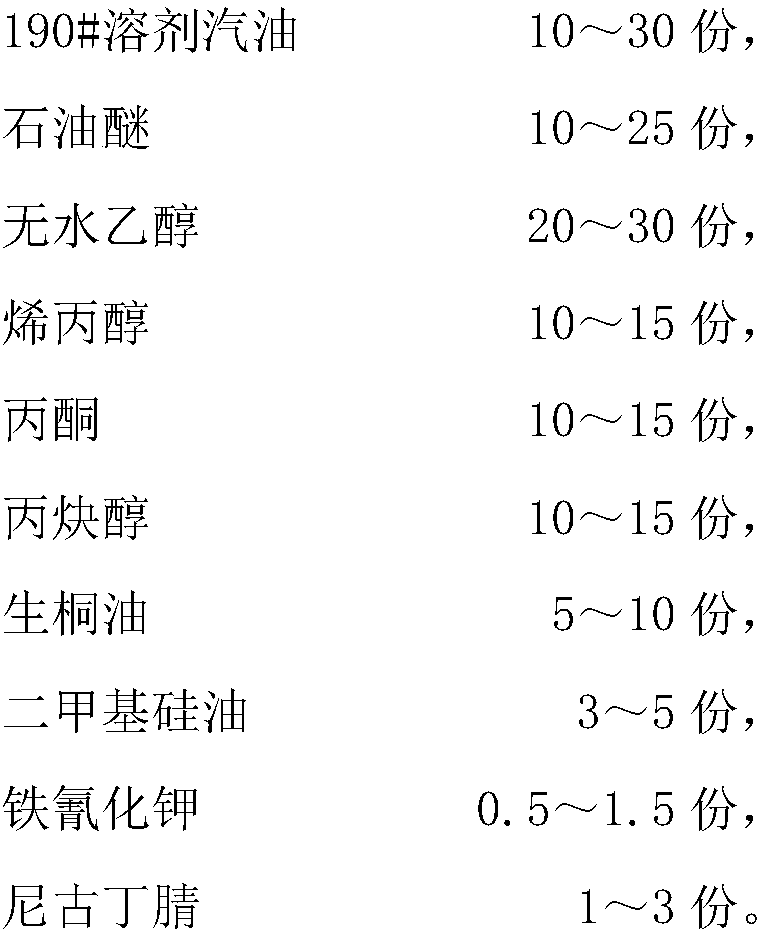

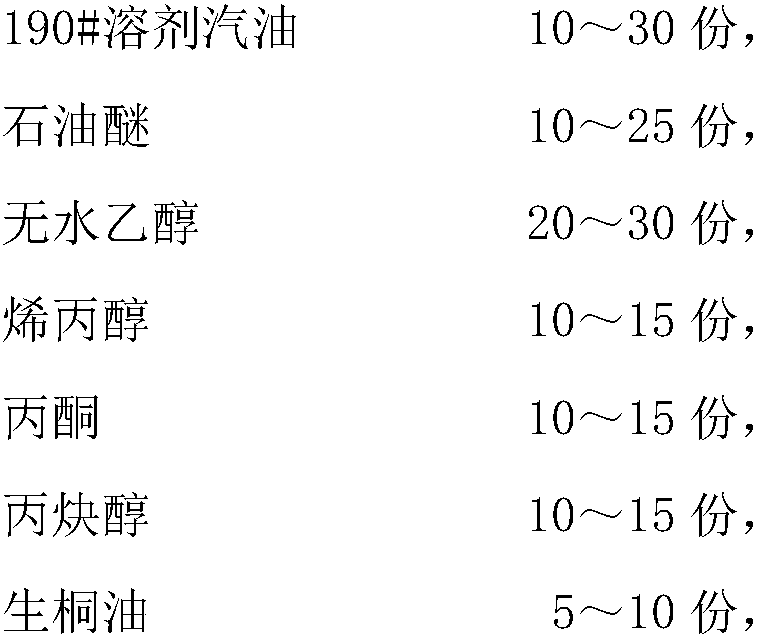

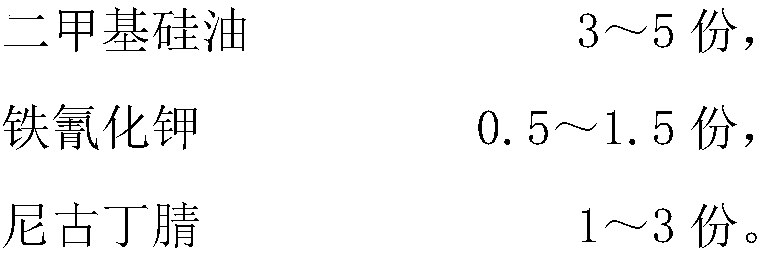

[0029] This embodiment relates to a method for preparing cutting gas capable of improving the thermal efficiency of methane gas combustion, the method comprising the following steps:

[0030] Step 1, preparation of catalytic warming agent:

[0031] (1) Dissolve 0.5 g of potassium ferricyanide in 10 g of acetone, stir evenly for 5 minutes, seal and place for 2 hours to dissolve to obtain potassium ferricyanide in acetone;

[0032] (2) 1.5g of nicotine nitrile was dissolved in 18g of petroleum ether, stirred evenly for 5 minutes, sealed and placed for 2 hours to fully dissolve, and nicotine nitrile petroleum ether solution was obtained;

[0033] (3) 10g of allyl alcohol is dissolved in 22g of absolute ethanol, and sealed for 2 hours to fully dissolve to obtain the allyl alcohol absolute ethanol solution;

[0034] (4) Potassium ferricyanide acetone solution, nicotine nitrile petroleum ether solution, allyl alcohol dehydrated alcohol solution and described 30g190# solvent gasolin...

Embodiment 2

[0037] This embodiment relates to a method for preparing cutting gas capable of improving the thermal efficiency of methane gas combustion, the method comprising the following steps:

[0038] Step 1, preparation of catalytic warming agent:

[0039] (1) Dissolve 1.5g of potassium ferricyanide in 15g of acetone, stir evenly for 5 minutes, seal and place for 2 hours to dissolve to obtain potassium ferricyanide in acetone;

[0040] (2) 1g of nicotine nitrile was dissolved in 10g of petroleum ether, stirred evenly for 5 minutes, sealed and placed for 2 hours to fully dissolve to obtain nicotine nitrile petroleum ether solution;

[0041] (3) 15g of allyl alcohol was dissolved in 20g of absolute ethanol, sealed and placed for 2 hours to fully dissolve to obtain the allyl alcohol absolute ethanol solution;

[0042] (4) Potassium ferricyanide acetone solution, nicotine nitrile petroleum ether solution, allyl alcohol absolute ethanol solution and described 10g190# solvent gasoline, 10g...

Embodiment 3

[0045] This embodiment relates to a method for preparing cutting gas capable of improving the thermal efficiency of methane gas combustion, the method comprising the following steps:

[0046] Step 1, preparation of catalytic warming agent:

[0047] (1) 1g of potassium ferricyanide is dissolved in 12g of acetone, stirred evenly for 5 minutes, sealed and left to dissolve for 2 hours to obtain potassium ferricyanide in acetone;

[0048] (2) 3g of nicotine nitrile was dissolved in 25g of petroleum ether, stirred evenly for 5 minutes, sealed and placed for 2 hours to fully dissolve to obtain nicotine nitrile petroleum ether solution;

[0049] (3) 13g of allyl alcohol was dissolved in 30g of absolute ethanol, sealed and placed for 2 hours to fully dissolve to obtain the allyl alcohol absolute ethanol solution;

[0050] (4) Potassium ferricyanide acetone solution, nicotine nitrile petroleum ether solution, allyl alcohol dehydrated alcohol solution and described 20g190# solvent gasol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com