Biomass boiler

A biomass boiler and drum technology, applied in the field of boilers, can solve the problems of continuous production impact, high flue gas flow rate, burnout equipment, etc., and achieve the effect of ensuring continuous operation, low flue gas flow rate and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

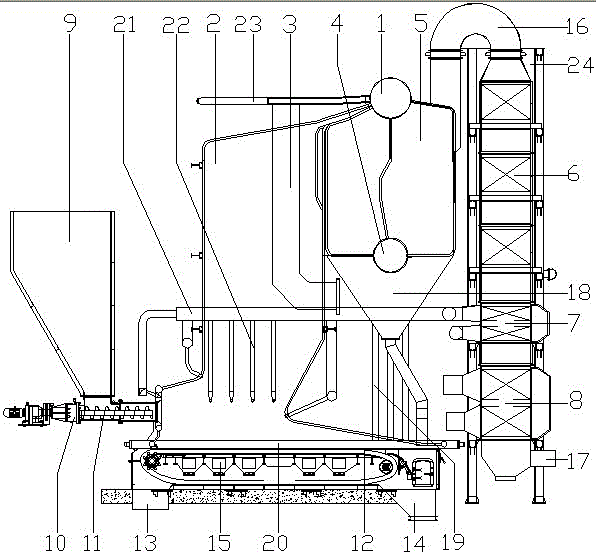

[0015] According to attached figure 1 , the drum of a biomass boiler is arranged above the furnace 2, and is divided into an upper drum 1 and a lower drum 4, the upper drum 1, the lower drum 4 are connected with the upper and lower ends of the convection tube bundle 5, and the upper drum 1 is connected with a water delivery pipe 23, and three connecting pipes 19 are arranged on each side of the lower part of the lower drum 4, and the lower end of the connecting pipe 19 is connected to the lower header 20. The water cooling system includes water cooling walls arranged on both sides of the furnace 2 (not shown in the figure) , connected to the water cooling screen 3 on the upper part of the furnace 2, the combustion system is provided with a scale-type chain grate 12, and the scale-type chain grate 12 is equipped with a feeder 10 at the front end of the furnace 2, and the feeder 10 is equipped with a front feeder 9. The feeder 10 is equipped with six screw auger feeding devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com