Sampling device for flue gas in close-to-wall zone of boiler water wall

A flue gas sampling and water-cooled wall technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of front-end sampling pipe blockage, small size of water-cooled wall fins, high temperature, etc., to avoid high-temperature corrosion and high operational reliability , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

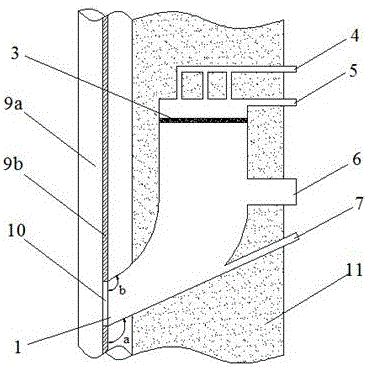

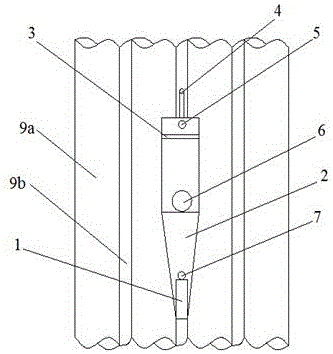

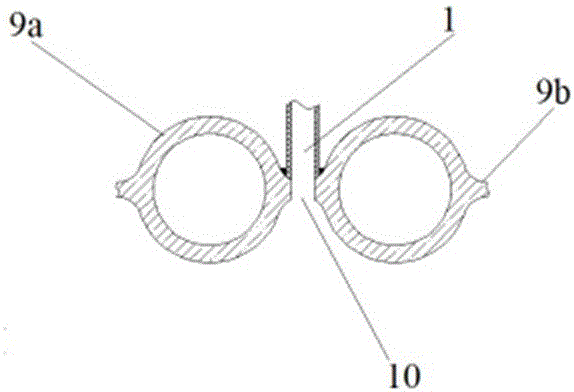

[0037] Such as figure 1 As shown, the flue gas sampling device near the wall of the boiler water wall of the present invention is installed in the thermal insulation layer of the boiler on the backfire side of the fins of the boiler water wall, and is mainly provided with a housing 2, and the housing 2 is provided with a flue gas inlet 1, The flue gas channel 8, the compressed air interface 4 and the flue gas outlet 5, the inner cavity of the shell is the flue gas channel 8, the flue gas inlet 1 and the flue gas outlet 5 are respectively arranged at both ends of the flue gas channel 8, and the flue gas inlet 1 is rectangular The mouth is arranged at the lower end of the shell 2, and the smoke outlet 5 is set at the upper end of the shell 2, and is located on the side opposite to the smoke inlet 1. The device is set in the insulation layer outside the boiler water wall, and a sampling port 10 matching the flue gas inlet 1 is opened on the boiler water wall fin, and the flue gas...

Embodiment 2

[0045] In this example, the bottom surface of the shell adopts a planar structure, and a transition section is provided between the corresponding flue gas channel and the flue gas inlet of the shell. The transition section adopts an arc-shaped structure except for the planar structure at the bottom. The curved structure and the bottom plane jointly form a gradually expanding structure at the lower part of the flue gas channel. All the other parts are the same as embodiment one.

Embodiment 3

[0046] Embodiment 3: In this example, the bottom surface of the housing adopts a planar structure, and the smoke inlet and the smoke outlet are arranged horizontally and directly on both sides of the smoke passage, without forming a gradual expansion structure at the lower part of the smoke passage. All the other parts are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com