Metal honeycomb heating element for gas stove

A honeycomb heating element and metal honeycomb technology, applied in the field of cookers, can solve the problems of honeycomb body porosity reduction, limited combustion efficiency, poor cooking experience, etc., and achieve the effects of high-efficiency combustion, combustion exhaust emission, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

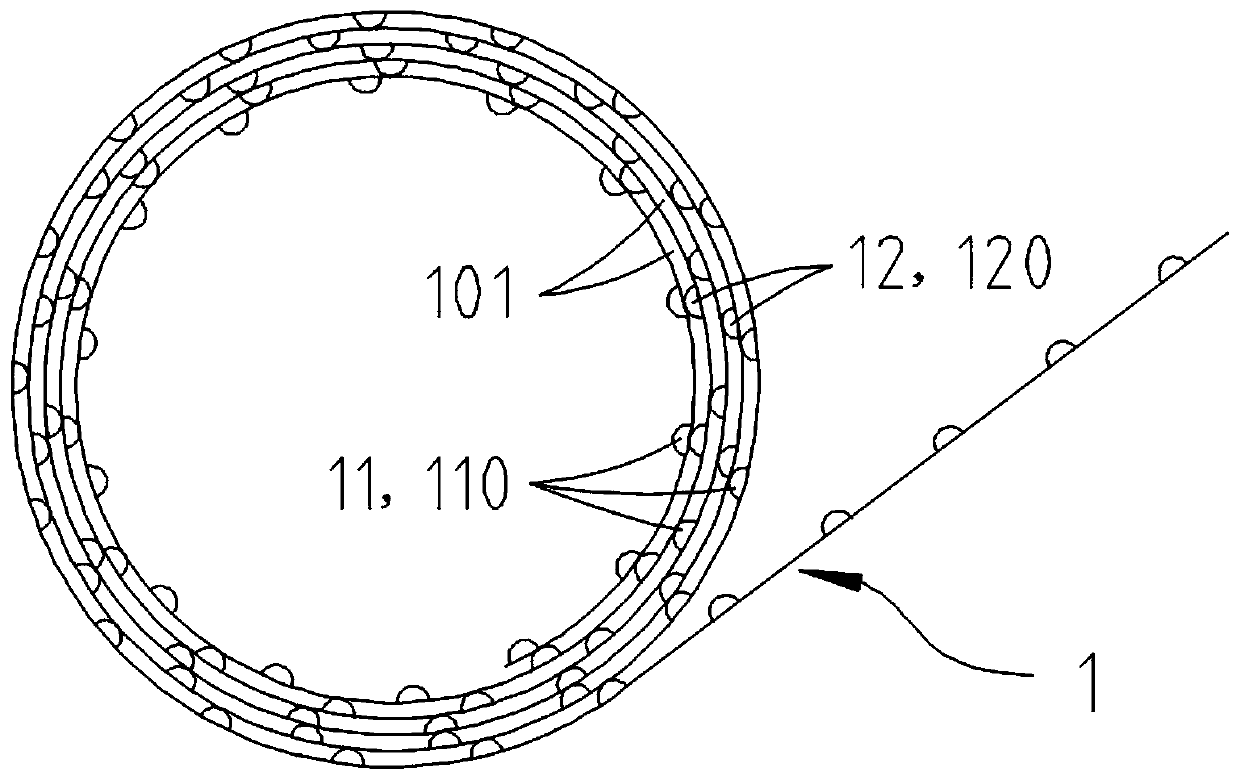

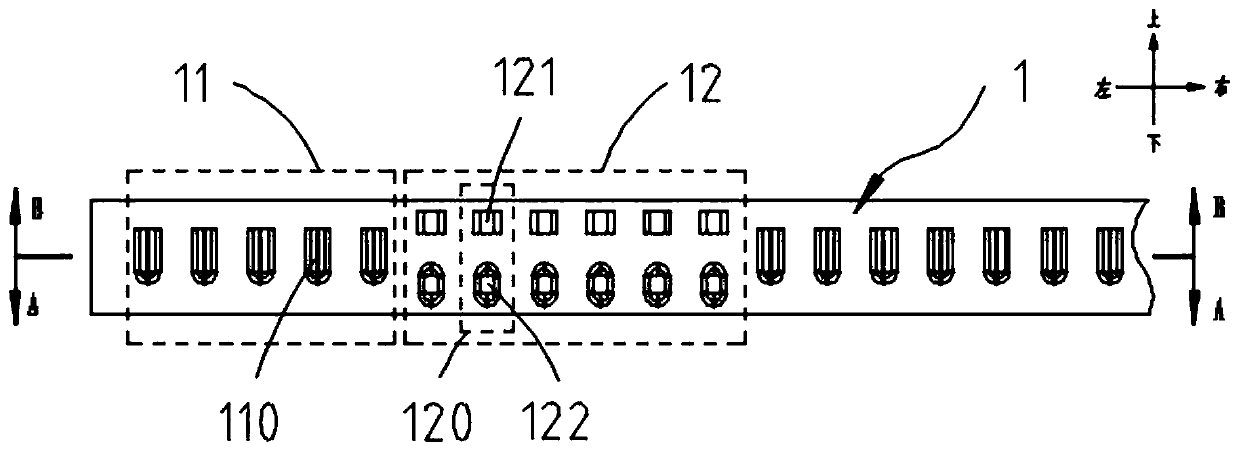

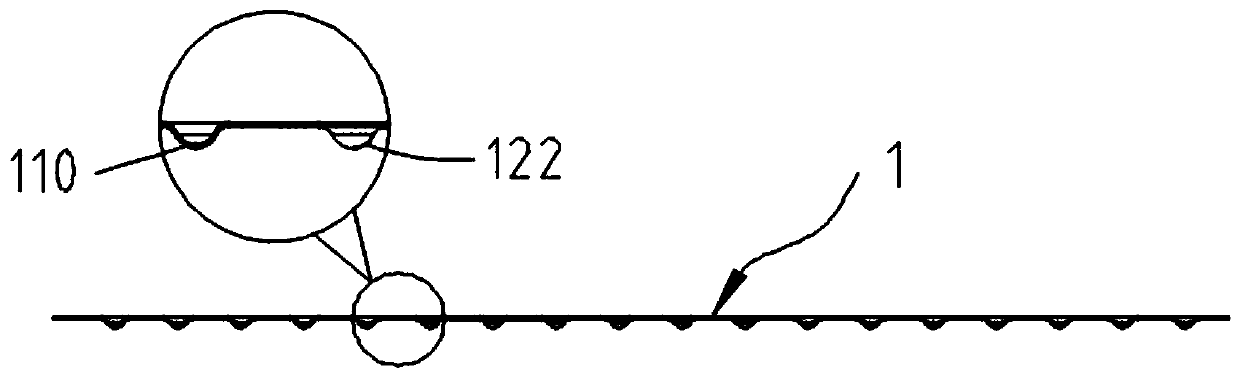

[0030] Such as Figure 1-2 As shown, a metal honeycomb heating element for a gas cooker includes a metal strip 1. On the same side of the metal strip 1, there are alternately arranged protrusion groups I11 and II12, and the metal strip 1 is coiled to form A honeycomb heating element with a plurality of coils, the protrusion group I11 and the protrusion group II12 are respectively arranged in any two adjacent coils, and a hole 101 for gas passage is formed between the adjacent coils, and the gas flows from the hole 101 is transferred to the upper surface of the honeycomb heating element for combustion. The protrusion group I11 and the protrusion group II12 include a plurality of protrusions 110, 120, the lower ends of the protrusions 110, 120 are closed, and the upper ends have openings to form a partial aperture 101. In this embodiment, the aperture 101 includes openings at the upper ends of the protrusions 110, 120, and air holes formed by the protrusions 110, 120 surrounding ...

Embodiment 2

[0040] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the upper end of the sub-protrusion 122 is formed as an opening for the air outlet 103, and the lower end is closed. Specifically, the sub-protrusion 122 is integrally stamped and formed by the metal strip 1, and the upper end of the sub-protrusion 122 is cut and separated from the metal strip 1 to form an opening, and the lower end is closed. The other parts are the same as in Embodiment 1.

[0041] It can be seen that by providing the opening as the air outlet 103 at the upper end of the sub-protrusion 122, this is beneficial to further increase the pore 101, making the porosity of the metal honeycomb heating element higher, and is more beneficial to improving the combustion efficiency and heating effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com