Burner

A burner and gas technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of mutual interference, easy backfire, blockage, etc., and achieve low emissions, improved combustion efficiency, and high power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

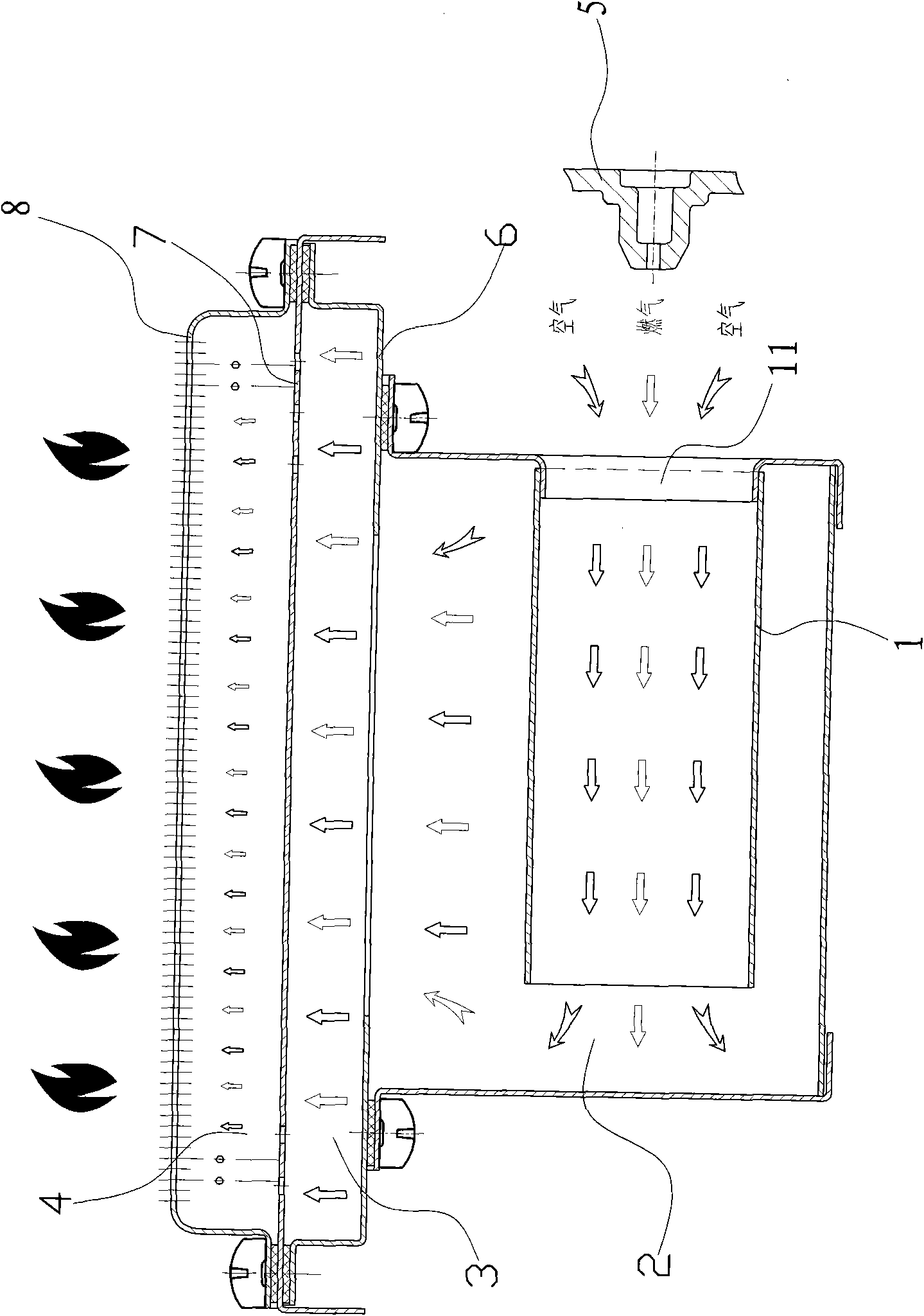

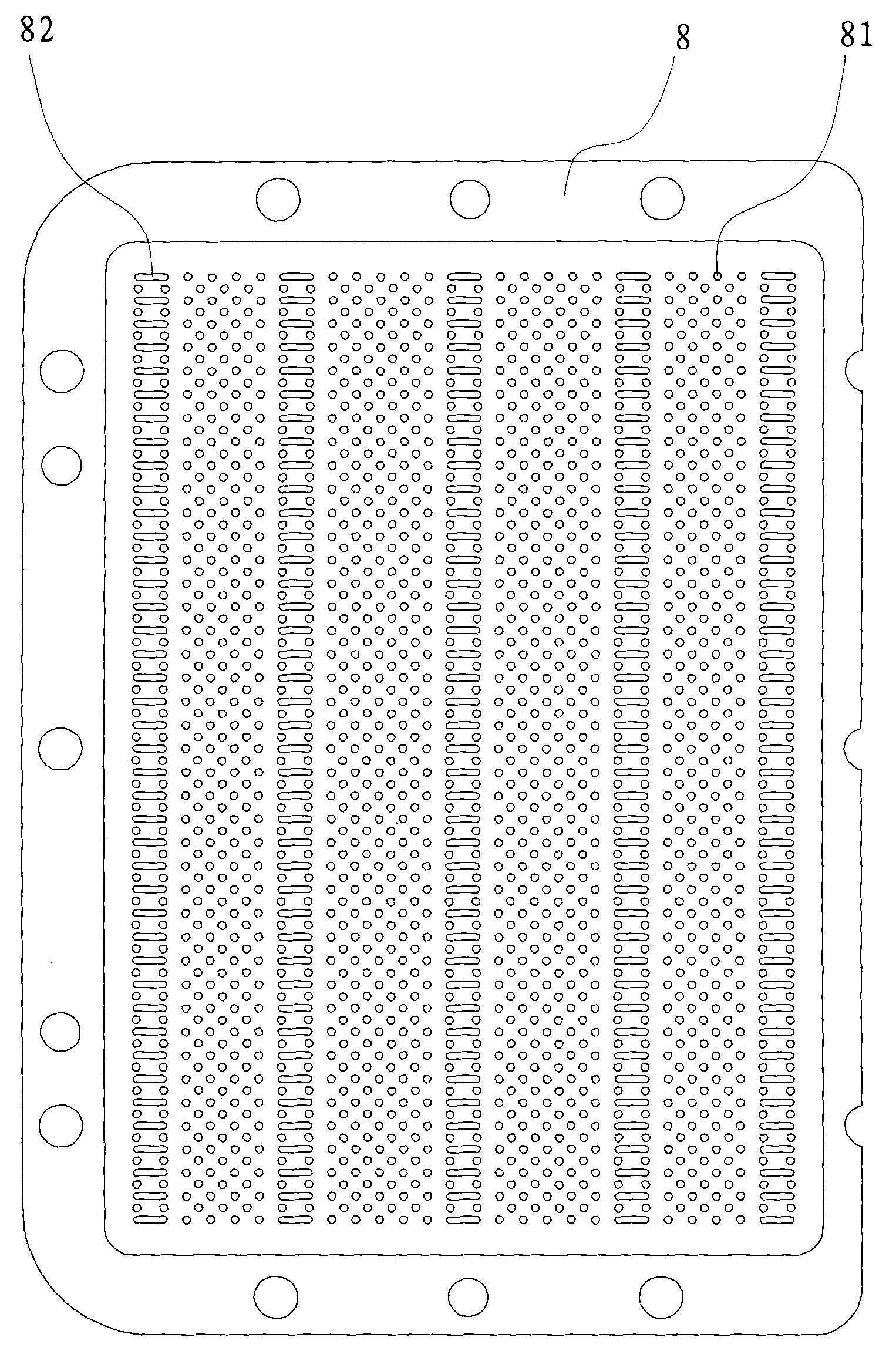

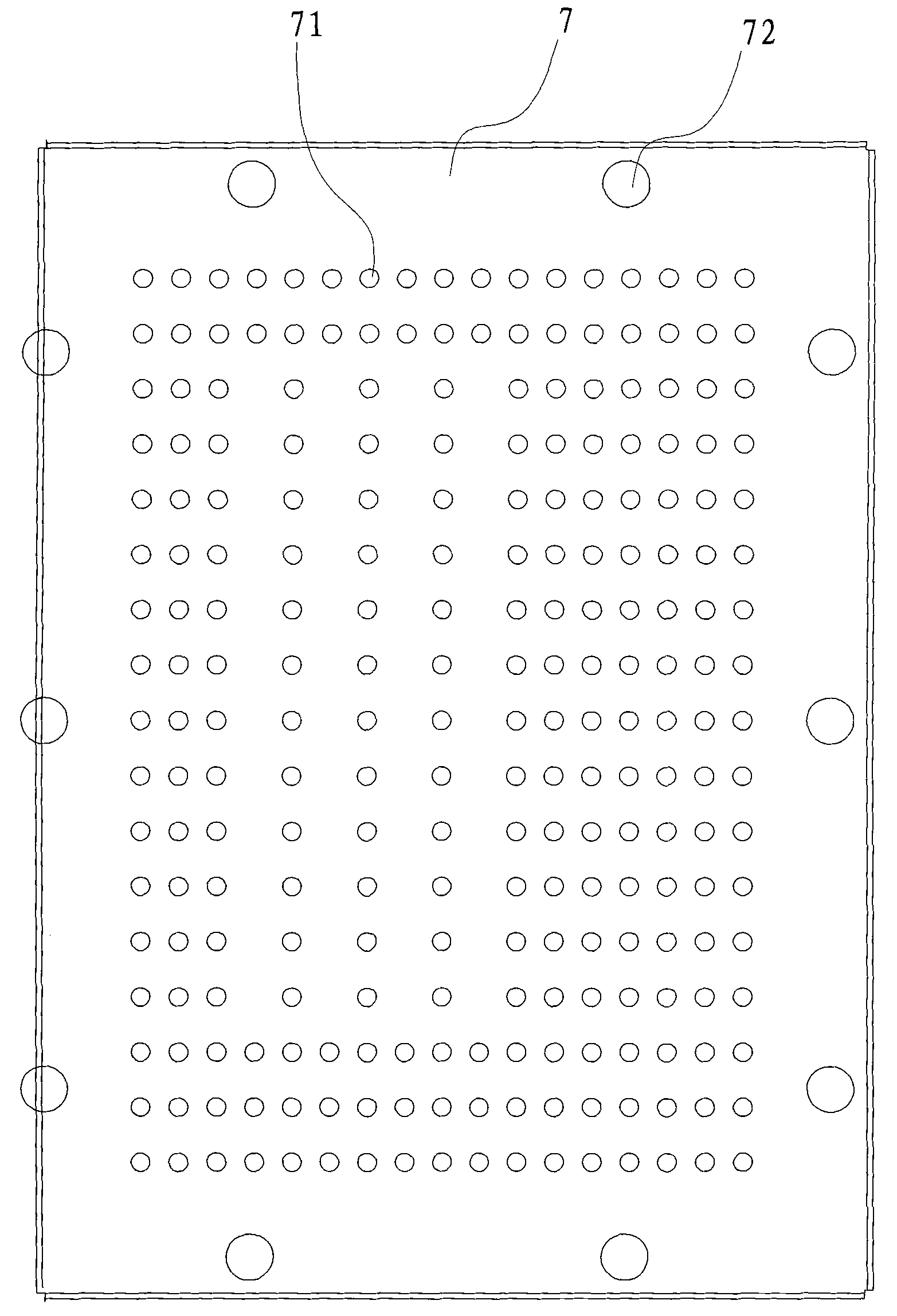

[0021] Such as figure 1 The shown burner includes a gas mixing chamber for mixing gas and air, and the gas mixing chamber includes a draft tube 1, a premixing chamber 2, a first mixing chamber 3 and a second mixing chamber 4, wherein the The air inlet 11 of the guide pipe 1 corresponds to the external nozzle 5, the air outlet of the guide pipe communicates with the premix chamber 2, and the first mixing chamber 3 is arranged in the premix chamber 2. The upper part, and separated by a baffle plate 6 with a middle opening 61, the second mixing chamber 4 is arranged on the upper part of the first mixing chamber 3, and separated by a flow plate 7, the flow plate 7 There are a plurality of air outlet holes 71 with a diameter of 2 mm distributed on the top, and there are mounting screw holes 72 around the flow equalizer. The top of the second mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com