Fully premixed metal fiber burner and boiler using the burner

A metal fiber, fully premixed technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the most stringent standard of 30 mg/m3, can not effectively adjust the ratio of air and gas, gas Uneven mixing with air and other problems can achieve the effect of improving the quality of combustion air, not easy to temper, and improving the quality of combustion and emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

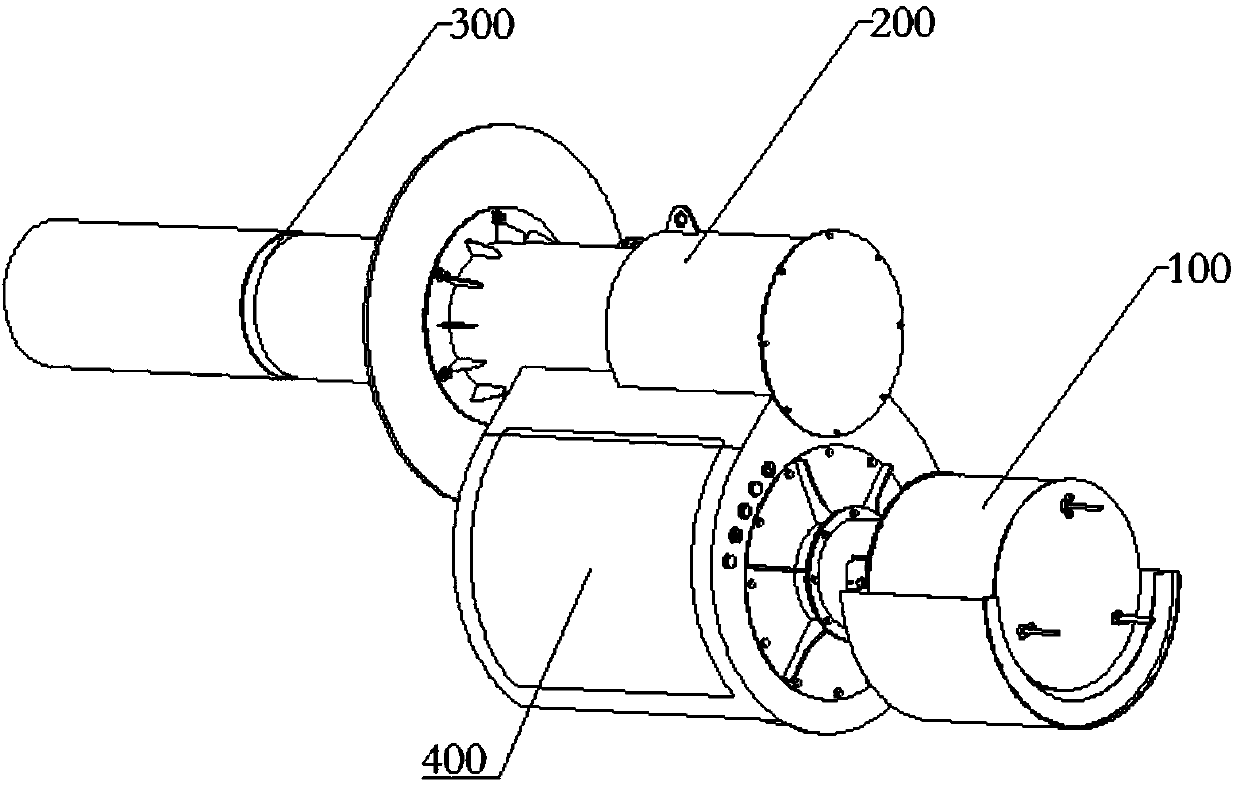

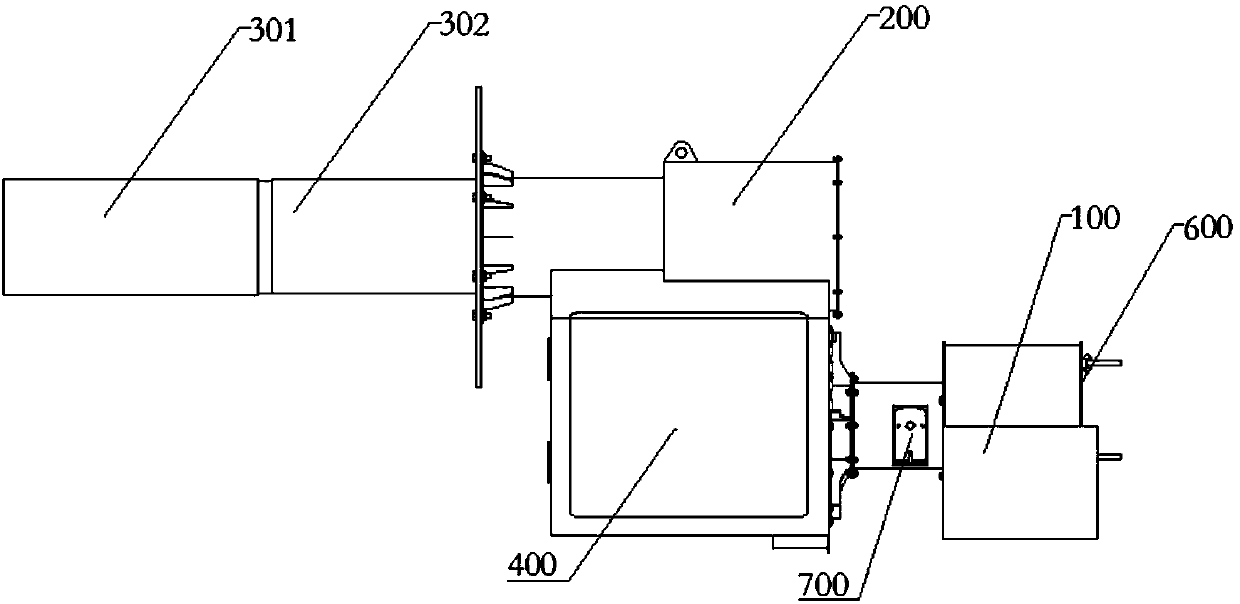

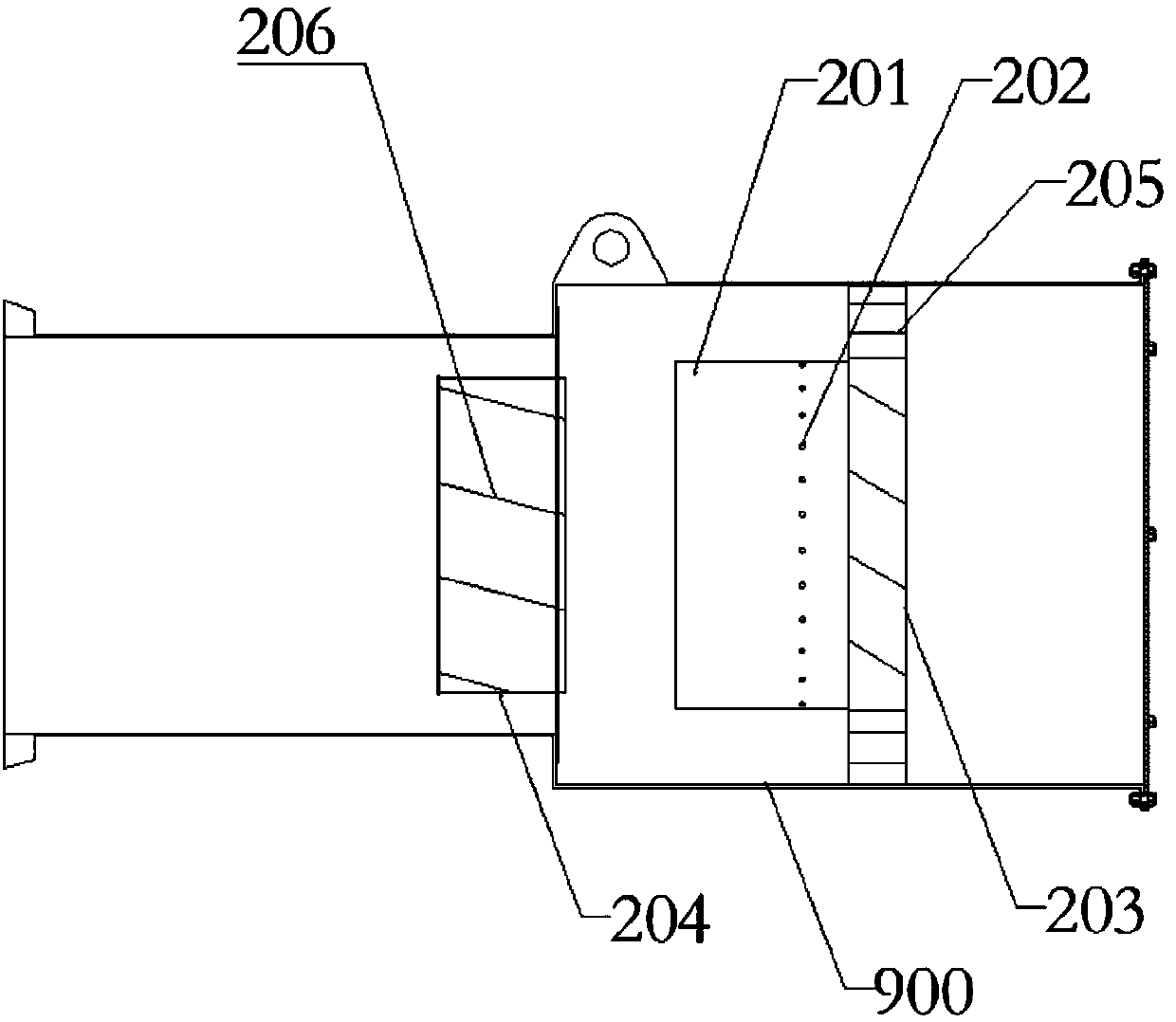

[0057] figure 1 A schematic diagram of the three-dimensional structure of the fully premixed metal fiber burner provided by the present invention, figure 2 for figure 1 The schematic diagram of the main view, image 3 The structure diagram of the air mixing unit provided by the present invention, such as Figure 1 to Figure 3 As shown, this embodiment provides a fully premixed metal fiber burner, including a fan 100, an air mixing unit 200 and a combustion head 300; the fan 100 is connected to the air mixing unit 200 to provide the air required for combustion; the air mixing The unit 200 is connected with the combustion head 300 for mixing and delivering the required air and gas mixture to the combustion head 300; A plurality of groups of through holes 202 are arranged in the direction, and a first air mixing disk 203 and a second air mixing disk 204 are arranged in sequence along the gas flow direction, and the air mixing pipe 201 is arranged between the first air mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com