Liquefied natural gas combustion aid

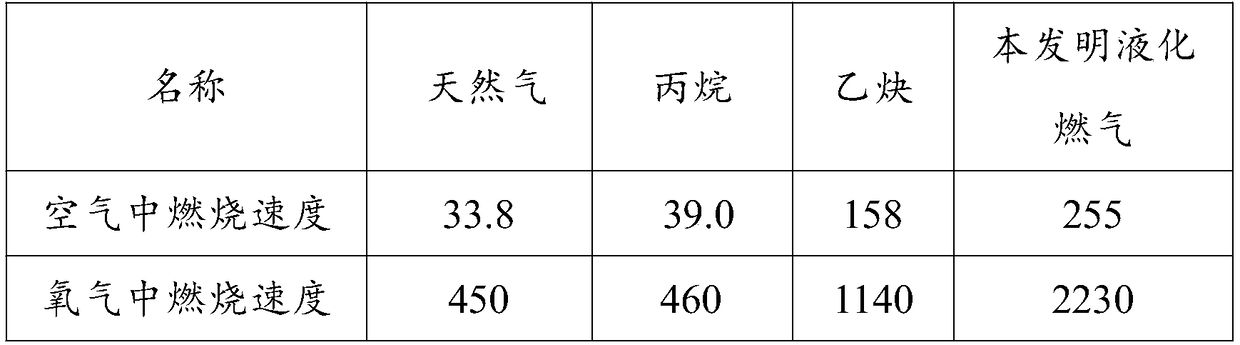

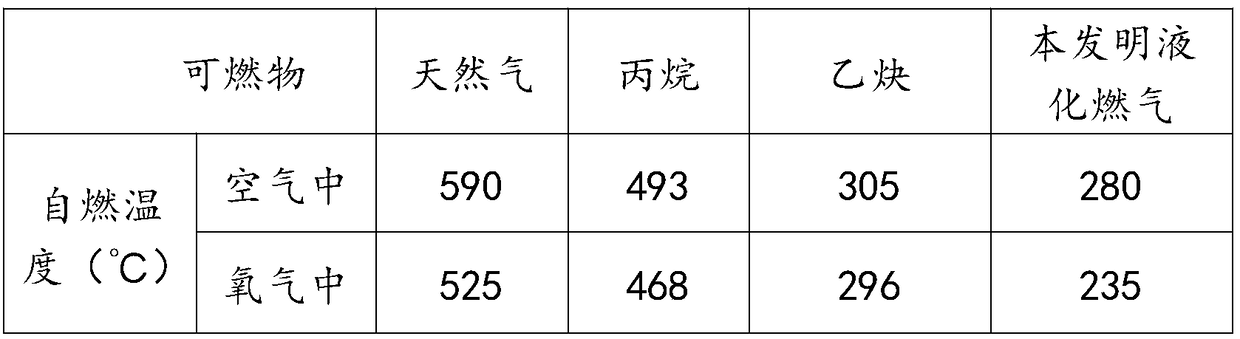

A technology of liquefied natural gas and combustion improver, which is applied in the direction of gas fuel, fuel, petroleum industry, etc. It can solve the problems of increased gas consumption, low combustion speed, and low combustion temperature, so as to save oxygen, increase the calorific value of gas, and increase the combustion speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of liquefied natural gas combustion improver: take 23 parts of tung oil, 15 parts of ethanol, 16 parts of n-butanol, 14 parts of cyclopentanol, 19 parts of ethylene glycol monobutyl ether, 8 parts of methyl ethyl ketone, and 5 parts of borane tetrahydrofuran , mix them uniformly and place them for 5 hours to obtain the liquefied natural gas combustion aid.

Embodiment 2

[0021] Preparation of liquefied natural gas combustion improver: take 24 parts of tung oil, 13 parts of ethanol, 16 parts of n-butanol, 14 parts of cyclopentanol, 18 parts of ethylene glycol monobutyl ether, 8 parts of methyl ethyl ketone, and 7 parts of borane tetrahydrofuran , mix them uniformly and place them for 5 hours to obtain the liquefied natural gas combustion aid.

Embodiment 3

[0023] Preparation of liquefied natural gas combustion improver: 25 parts of tung oil, 12 parts of ethanol, 16 parts of n-butanol, 14 parts of cyclopentanol, 18 parts of ethylene glycol monobutyl ether, 9 parts of methyl ethyl ketone, and 6 parts of borane tetrahydrofuran. Mix them uniformly and leave them for 5 hours to obtain the liquefied natural gas combustion aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com