Burner for outputing thick and thin premixed gas by using small fire holes and conical tubular fire holes

A technology of gas burners and small fire holes, which is applied in the directions of gas fuel burners, burners, combustion methods, etc., to achieve the effect of improving heat exchange intensity and efficiency, not easy to temper, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

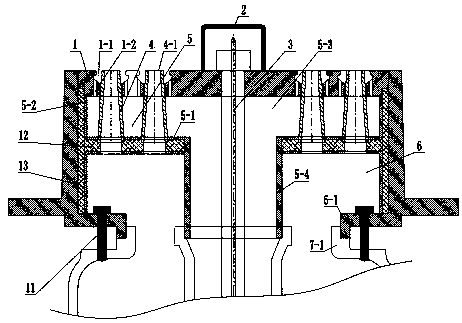

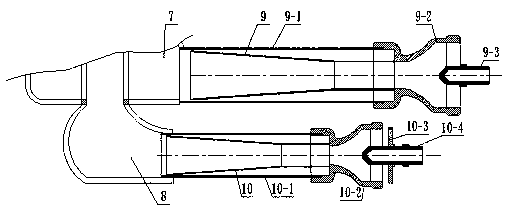

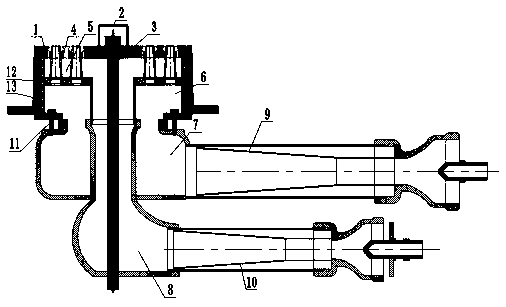

[0020] Combine below Figure 1-3 Describe this embodiment, use the small fire hole and the conical tubular fire hole to output the rich-lean premixed gas burner, including the fire distributor 1, the annular groove 1-1, the auxiliary fire hole 1-2, the cap 2, the ignition and flameout protection needle 3, Conical pipe 4, main fire hole 4-1, auxiliary distribution chamber 5, auxiliary distribution chamber bottom plate 5-1, auxiliary distribution chamber side plate 5-2, auxiliary distribution chamber premixed gas inlet 5-3, gas pipeline 5- 4. Main distribution chamber 6, closing port 6-1, main transfer chamber 7, annular throat 7-1, auxiliary transfer chamber 8, main ejector 9, bushing 9-1, main bell mouth 9-2, gas nozzle 9-3, auxiliary ejector 10, auxiliary sleeve 10-1, auxiliary bell mouth 10-2, air conditioning baffle 10-3 and auxiliary gas nozzle 10-4.

[0021] There are inner and outer ring grooves 1-1 on the fire distributor 1, an ignition and flameout protection pin 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com