Energy-saving environment-friendly engine

An energy saving, environmental protection, engine technology, applied in the direction of machines/engines, mechanical equipment, gas turbine devices, etc., can solve the problems of wide land occupation, large investment in single machine, and many supporting facilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

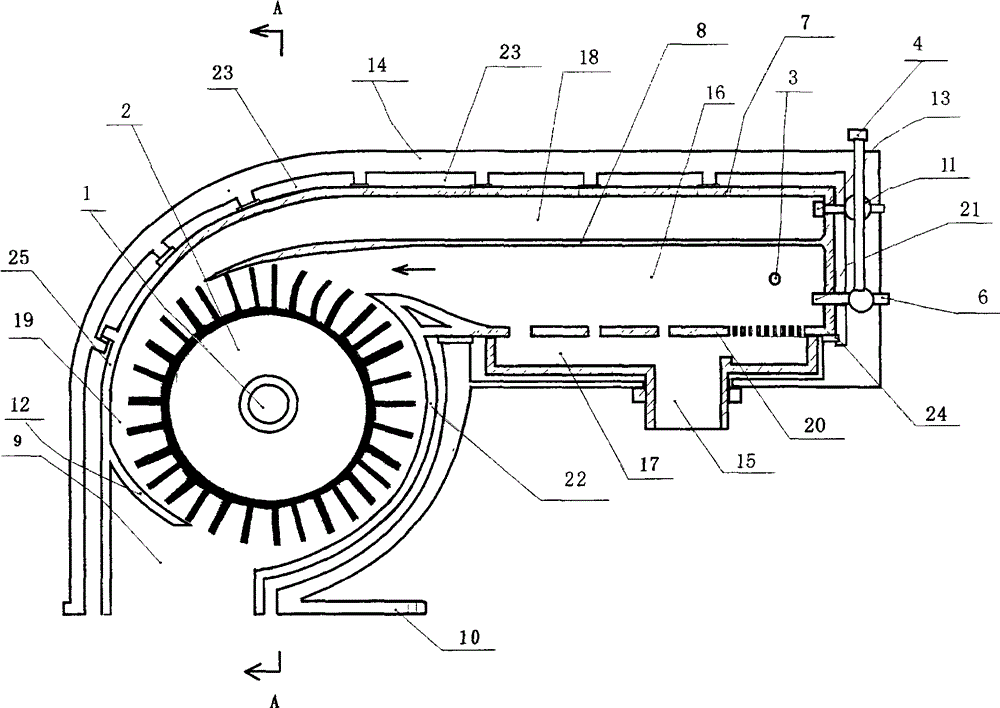

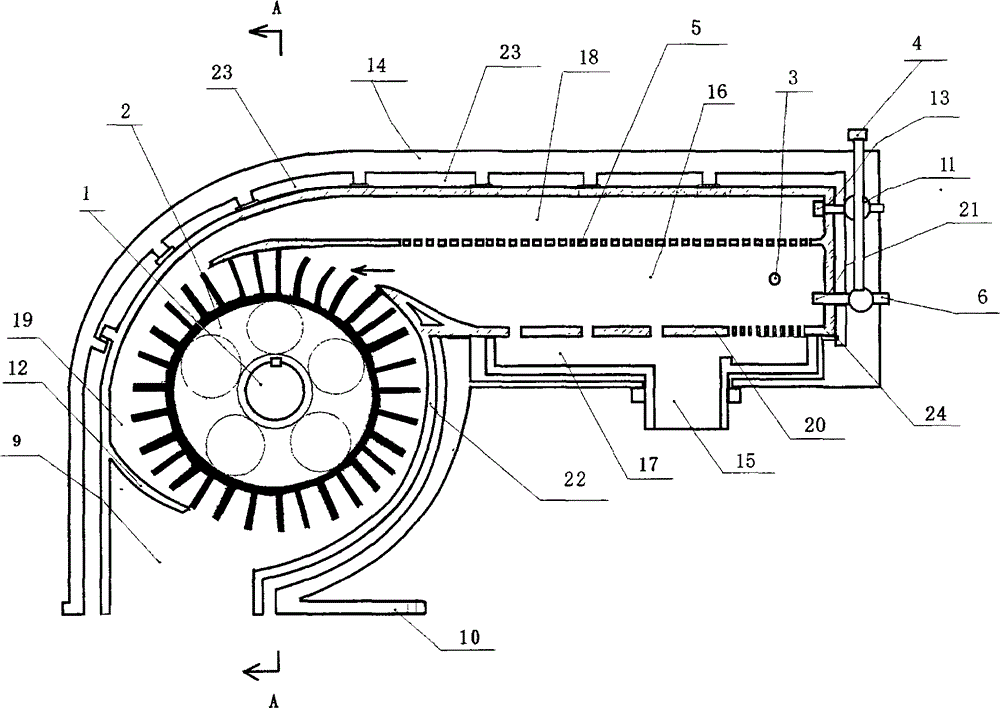

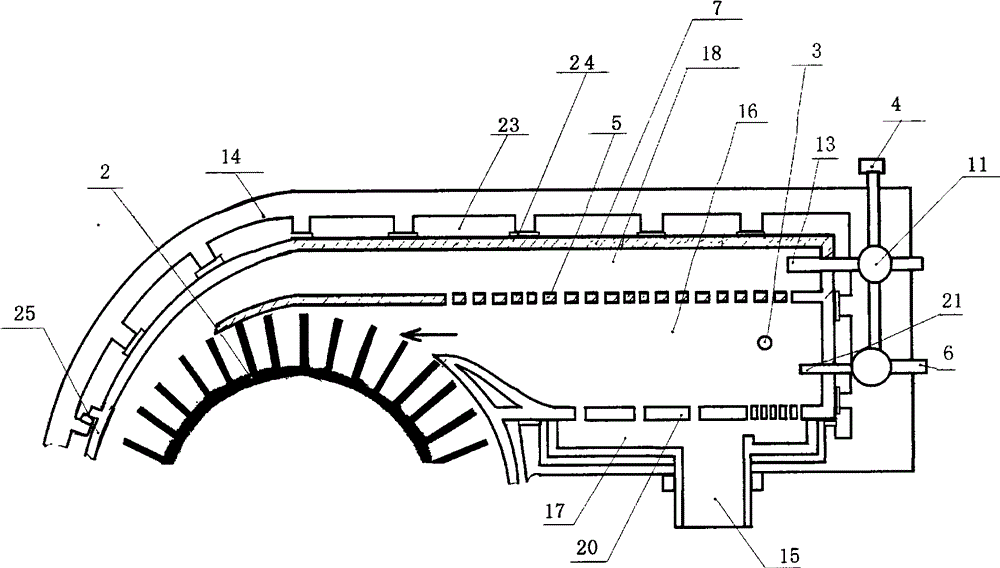

[0027]An energy-saving and environment-friendly engine of the present invention, when the starting motor drives the main shaft to rotate, the air compressor rotates, and a large amount of high-density fresh air is immediately poured into the combustion chamber in the gas direct injection cylinder (16), and the fuel nozzle injects fuel and air The mixed gas can be highly mixed at the moment of mixing, and the internal fuel of the spark plug ignited gas direct injection cylinder (16) burns rapidly and violently, and the impinging airflow produced by it directly impacts and drives the impeller to rotate. The inside of the ultra-supercritical steam injection cylinder (18) is heated by its heat radiation sheet (8) and quickly becomes a high-temperature heat radiation steel plate at about 1000°C (the temperature of the cylinder body is about 600°C under normal conditions, and the heat radiation sheet (8) At about 1000°C), when water is sprayed into the ultra-supercritical steam injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com