Anti-flashback nozzle and combustion device with the same

A technology of combustion equipment and nozzles, which is applied in the field of flame-type heating equipment and anti-backfire nozzles. It can solve problems such as complexity, affecting the temperature of the furnace body, and poor flame stability, and achieves simplified installation, high nozzle adjustment ratio, and high flame stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

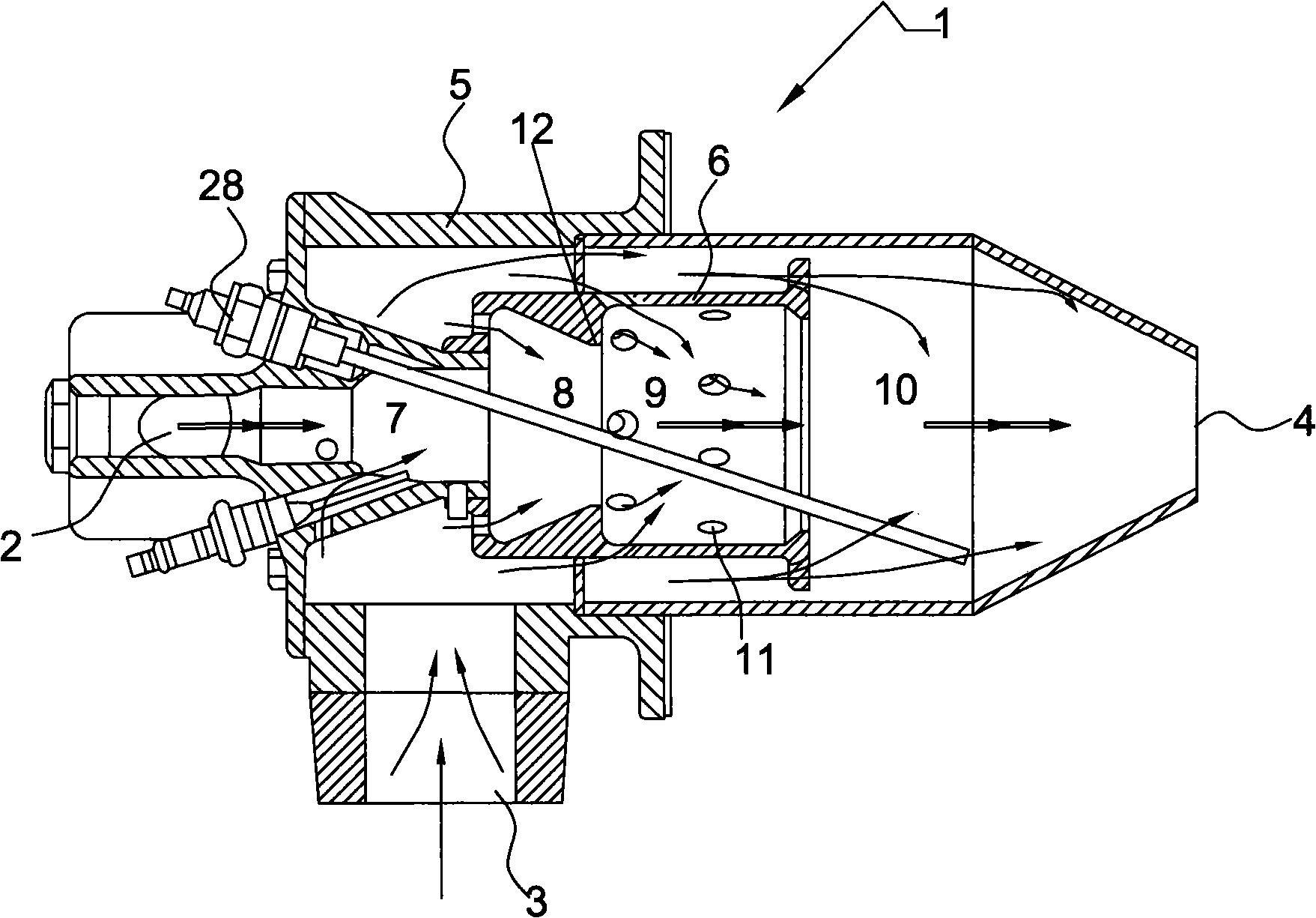

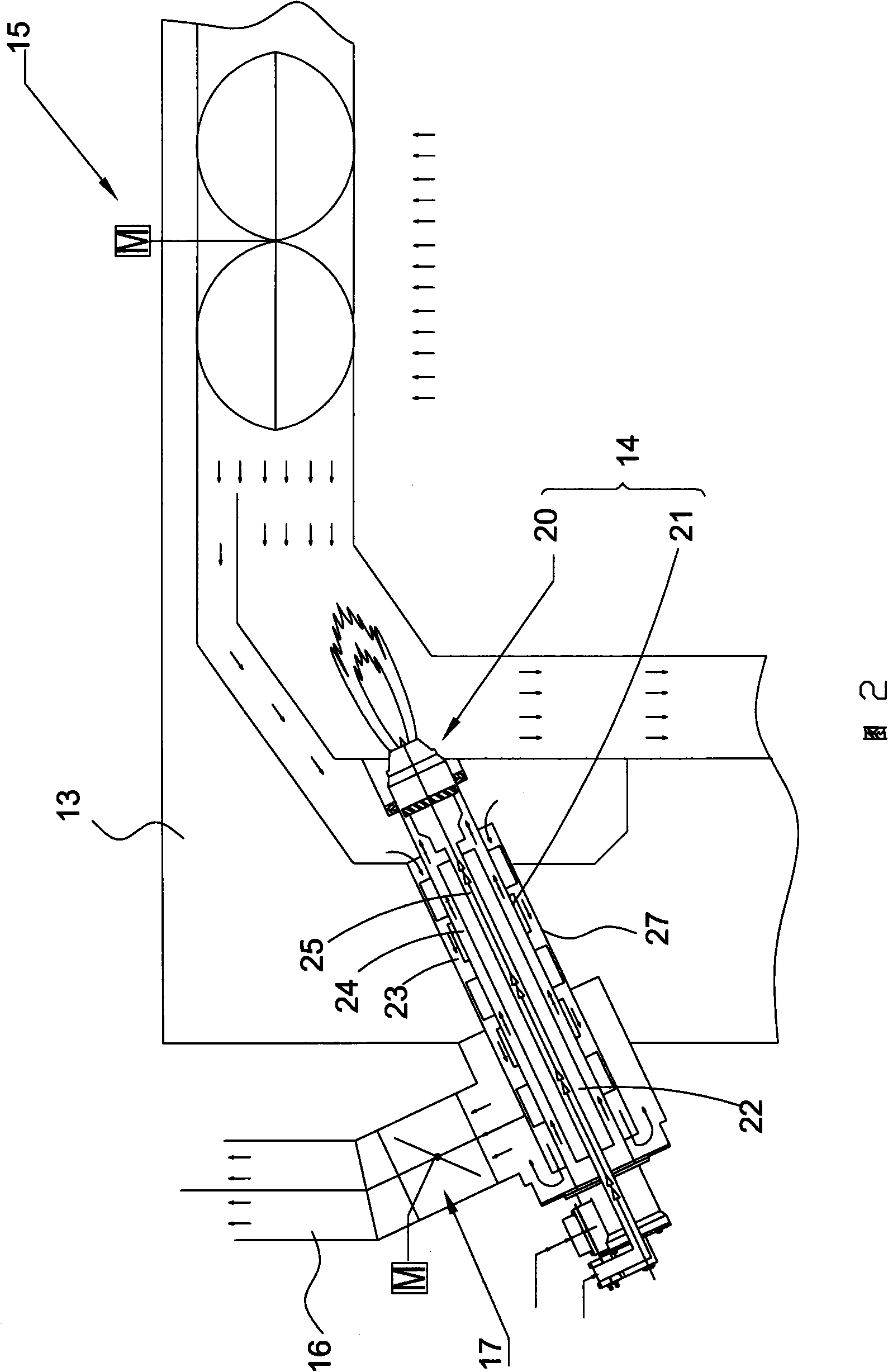

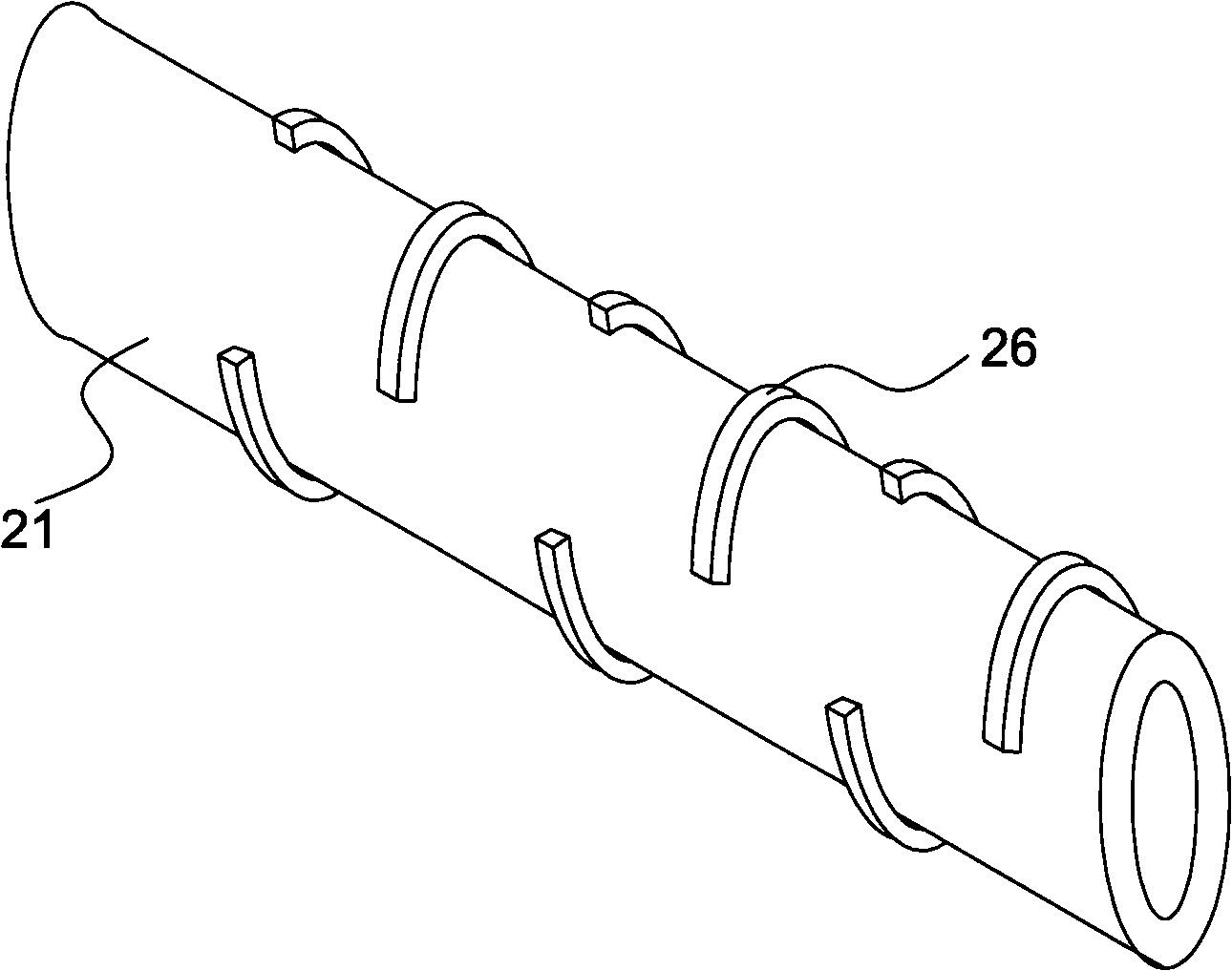

[0043] attached figure 1 Shown as a preferred embodiment of the present invention, it discloses the internal structure of the anti-backfire nozzle of the present invention, accompanying drawing 2 discloses the internal structure of a kind of combustion equipment with above-mentioned anti-backfire nozzle, below in conjunction with accompanying drawing to this The working principle and structure of the invention are introduced in detail.

[0044] A kind of combustion equipment, it comprises: a furnace body 13, a burner 14 partially located in the furnace body 13, a circulation fan 15 arranged in the furnace body 13, a flue exhaust duct 16 connected to the outside world, wherein the circulation fan 15 After the airflow in the furnace body 13 is drawn out, it is discharged through its air outlet. Part of the airflow blown out from the air outlet enters the exhaust duct 16 and becomes exhaust gas, and part of it exchanges heat with the flame of the burner 14 and remains in the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com