Digital integrated mass vortex-shedding meter

A vortex flowmeter and mass technology, which is applied to indirect mass flowmeters, mass flow measurement devices, etc., can solve the problems of no state identification function, difficulty in measuring small flow, and difficulty in accurately measuring sensor frequency, amplitude and differential pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

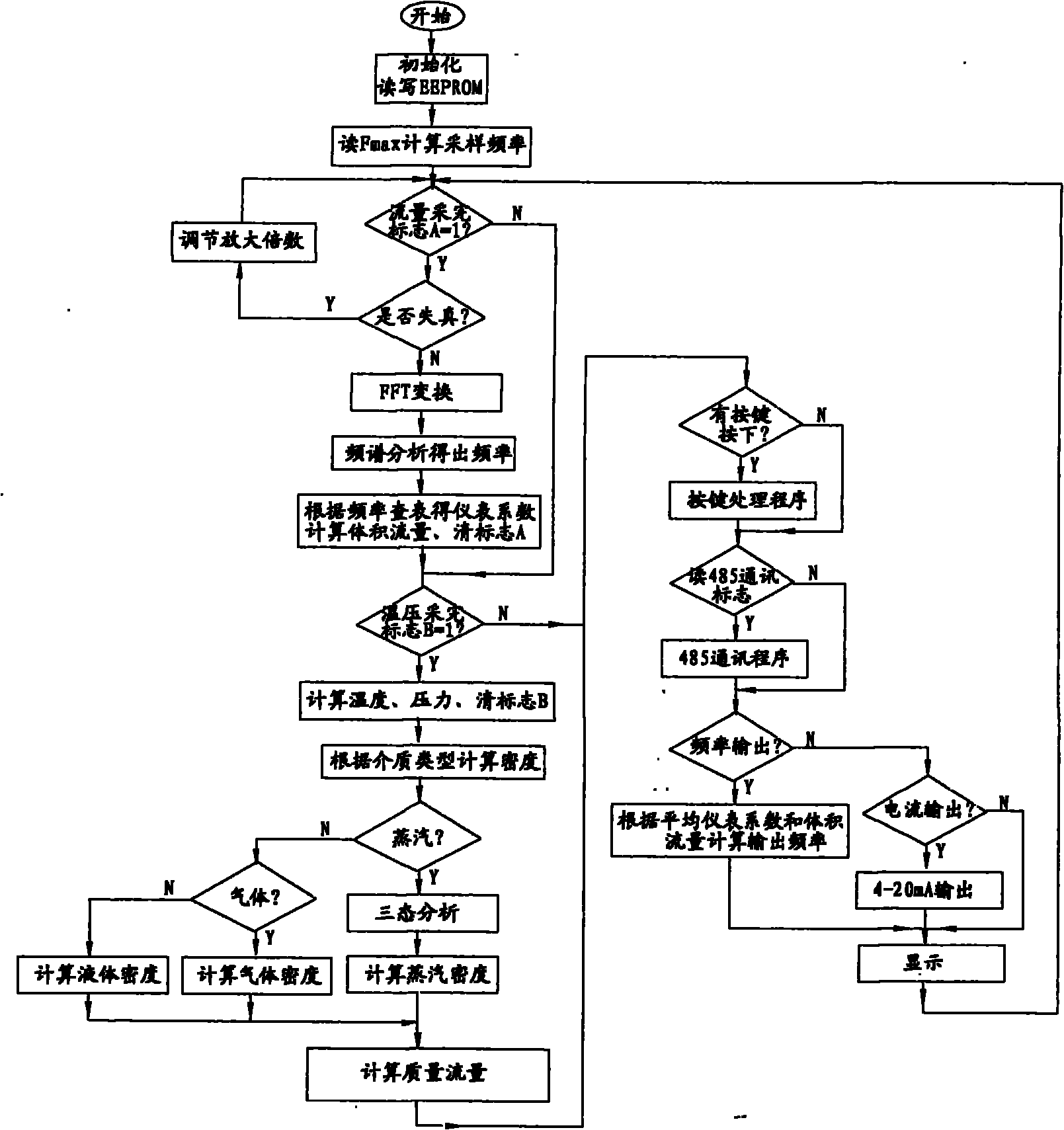

[0049] Below in conjunction with accompanying drawing, the present invention will be further described and supplemented

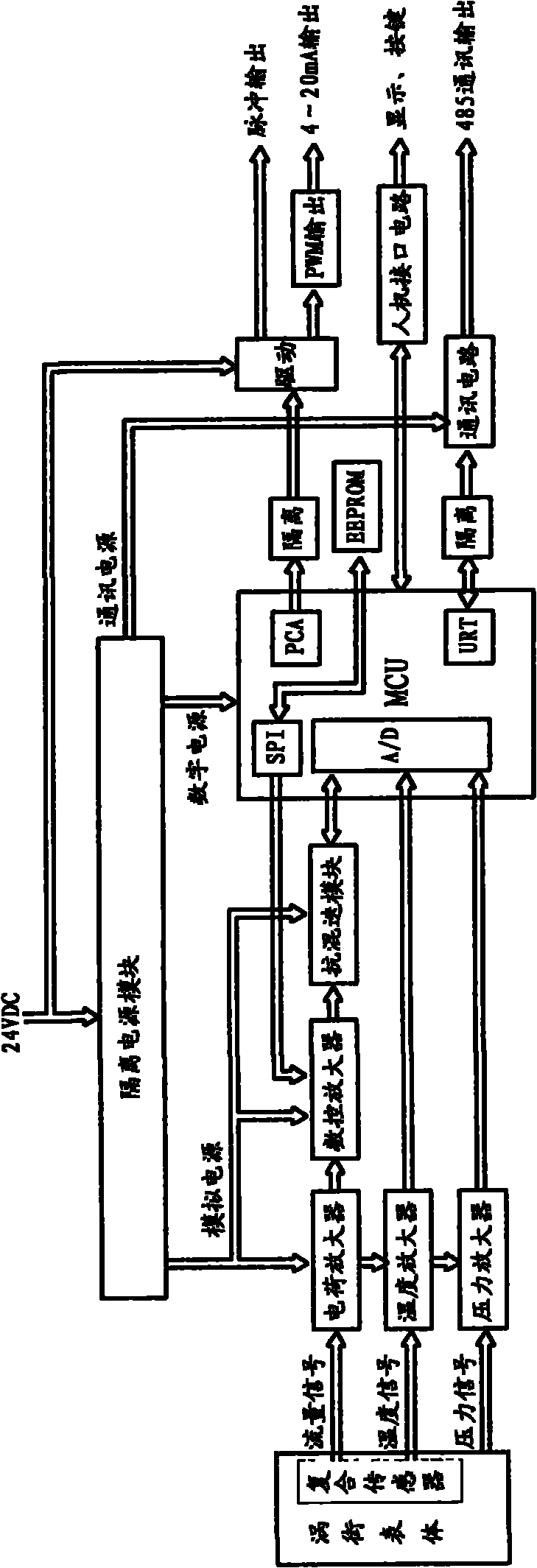

[0050] First, look at the hardware configuration and the connection relationship with each part:

[0051] Such as figure 1 As shown, the first block on the left in the figure is the meter body and the composite sensor, and the composite sensor includes a piezoelectric and temperature composite sensor and a pressure composite sensor. The piezoelectric and temperature compound sensor is assembled to the vortex meter body through a housing, and the pressure compound sensor is directly assembled to the vortex meter body. The meter body and the composite sensor work together to detect the vortex frequency, temperature and pressure signals of the fluid in the pipeline at the same time.

[0052] The rest of the figure is composed of digital processor hardware. Among them, the charge amplifier, numerical control amplifier, and anti-aliasing circuit are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com