System and method for producing high-time diluted PM2.5 aerosol

An aerosol generation and aerosol technology, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve problems such as inability to form aerosols, easily destroy the physical and chemical properties of particles, and inability to control gas flow well, so as to alleviate Effect of Aerosol Particle Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

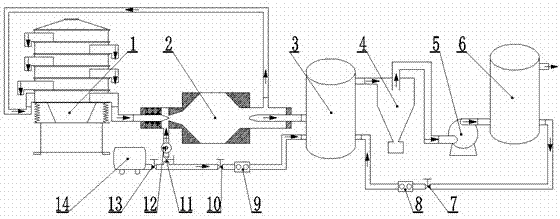

[0022] Such as figure 1 As shown, high dilution PM 2.5 The aerosol generation system includes a vibrating screen feeder 1, an aerosol duster and a primary diluter 2, an aerosol buffer tank and a secondary diluter 3, PM 2.5 Separator 4, induced draft fan 5, aerosol buffer tank 6, return air flow control valve 7, return air flow meter 8, secondary diluter compressed air supply flow meter 9, secondary diluter compressed air supply control Valve 10, primary diluter jet air pressure control valve 11, primary diluter jet air pressure pressure gauge 12, air compressor supply air flow control valve 13, air compressor 14; vibrating screen feeder 1, aerosol dust blower And primary diluter 2, aerosol buffer tank and secondary diluter 3, PM 2.5 The separator 4, the induced draft fan 5, and the aerosol buffer tank 6 are connected in sequence, the aerosol buffer tank 6 returns the outlet, the return air flow control valve 7, the return air flow meter 8, the aerosol buffer tank and the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com