Powder feeding and mixing device for preparing magnetic grinding material through atomization and rapid solidification and powder feeding and mixing method

A magnetic abrasive and powder mixer technology, applied in chemical instruments and methods, mixing methods, fluid mixers, etc., can solve the problems of reduced grinding efficiency, incomparable grinding capacity, and low content of ceramic hard abrasives. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

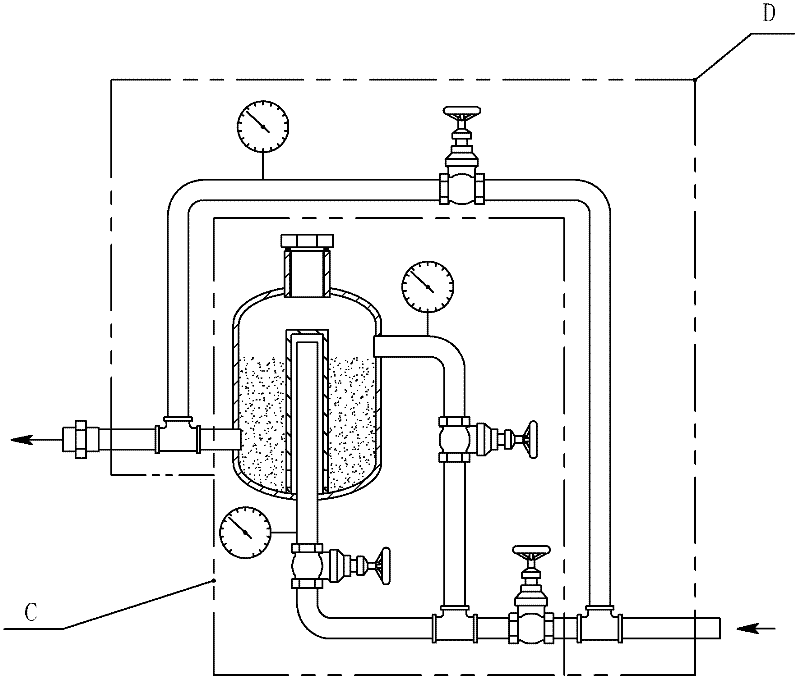

[0041] figure 1 Winning mark: C powder feeding device; D powder mixing device.

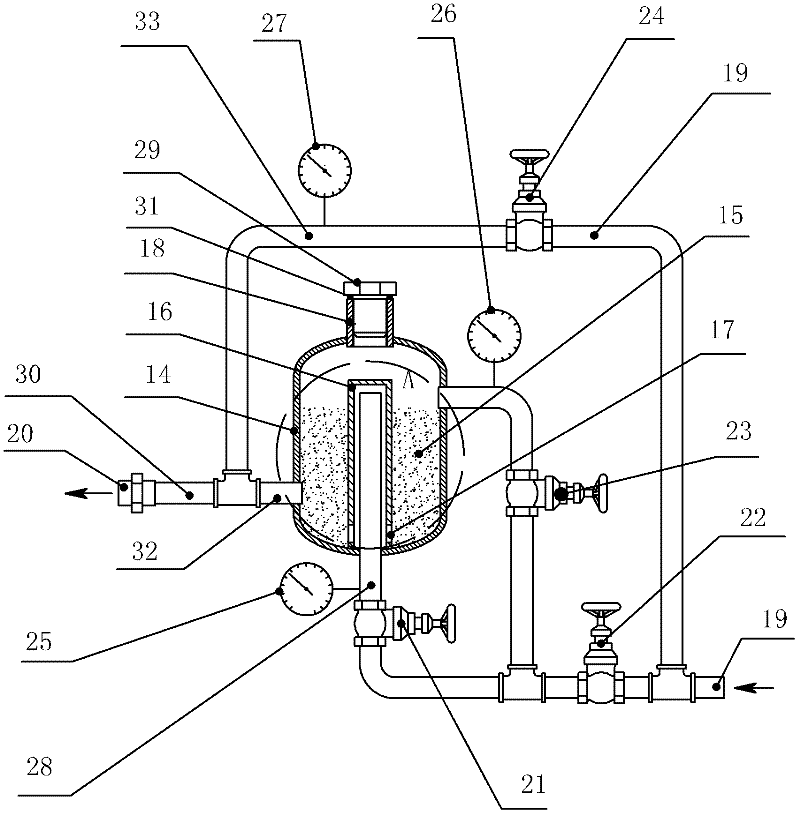

[0042] figure 2 Winning marks: 14 material storage tank; 15 hard abrasive; 16 round tube cover; 17 nozzle hole at the bottom of the round tube cover; 18 feeding port; 19 high-pressure air inlet pipe; 20 jet output port; ;23 Balance valve; 24 Jet pressure control valve; 25 Injection barometer; 26 Balance barometer; 27 Jet barometer; 28 Injection pipe; Tube; 33 jet pressure control trachea.

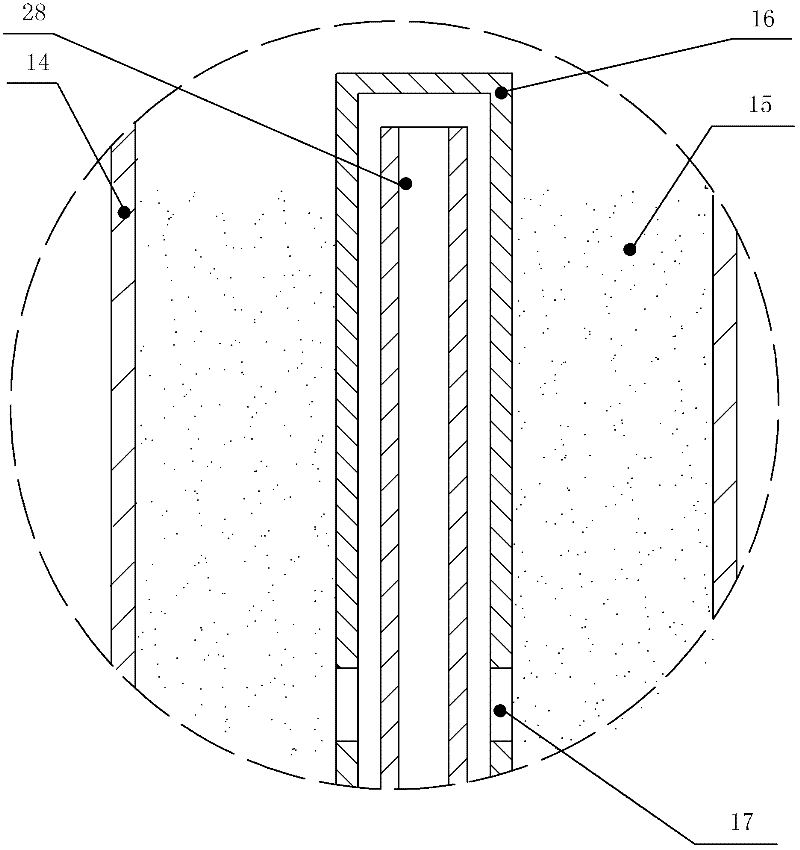

[0043] image 3 Winning marks: 14 material storage tank; 15 hard abrasive; 16 round pipe cover; 17 nozzle hole at the bottom of round pipe cover; 28 injection pipe.

[0044] Figure 4 Winning marks: 1 electric furnace; 2 molten metal; 3 heat preservation crucible; 4 leak nozzle; 5 atomization chamber; 6 air extraction and dust removal device; 7 dust collector; Air flow to the powder mixer; 13 jet nozzles.

[0045] see figure 1 . figure 1 Preparation of powder feeder and mixer for gas-atomized fast-set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com