Disc type dust dispersedly generating apparatus using capacity quantitative dry method

A dry dispersion, disc technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of difficulty in meeting the needs of dust research, low dust generation accuracy, and insufficient dust generation capacity. To achieve the effect of simple structure, wide application range and stable dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

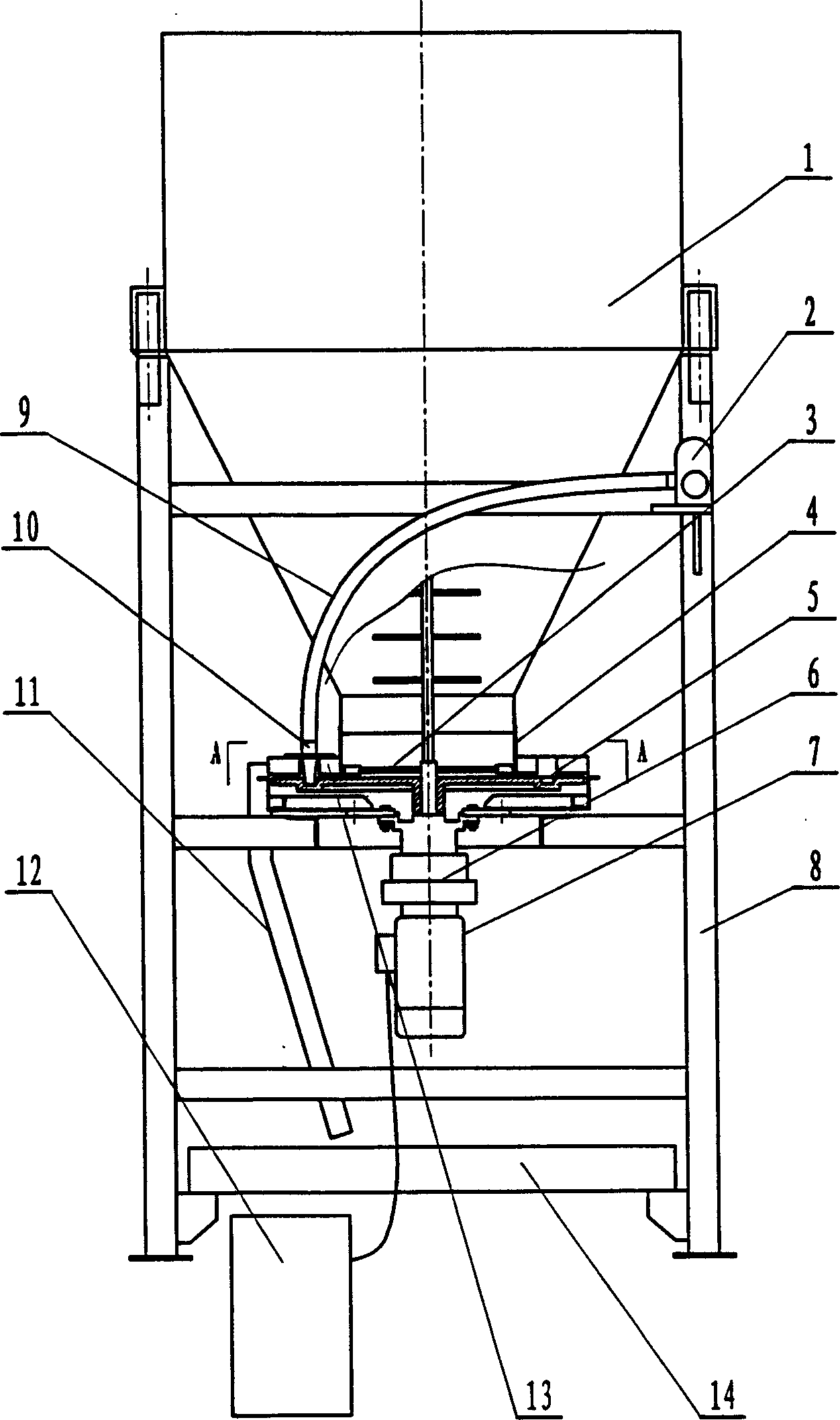

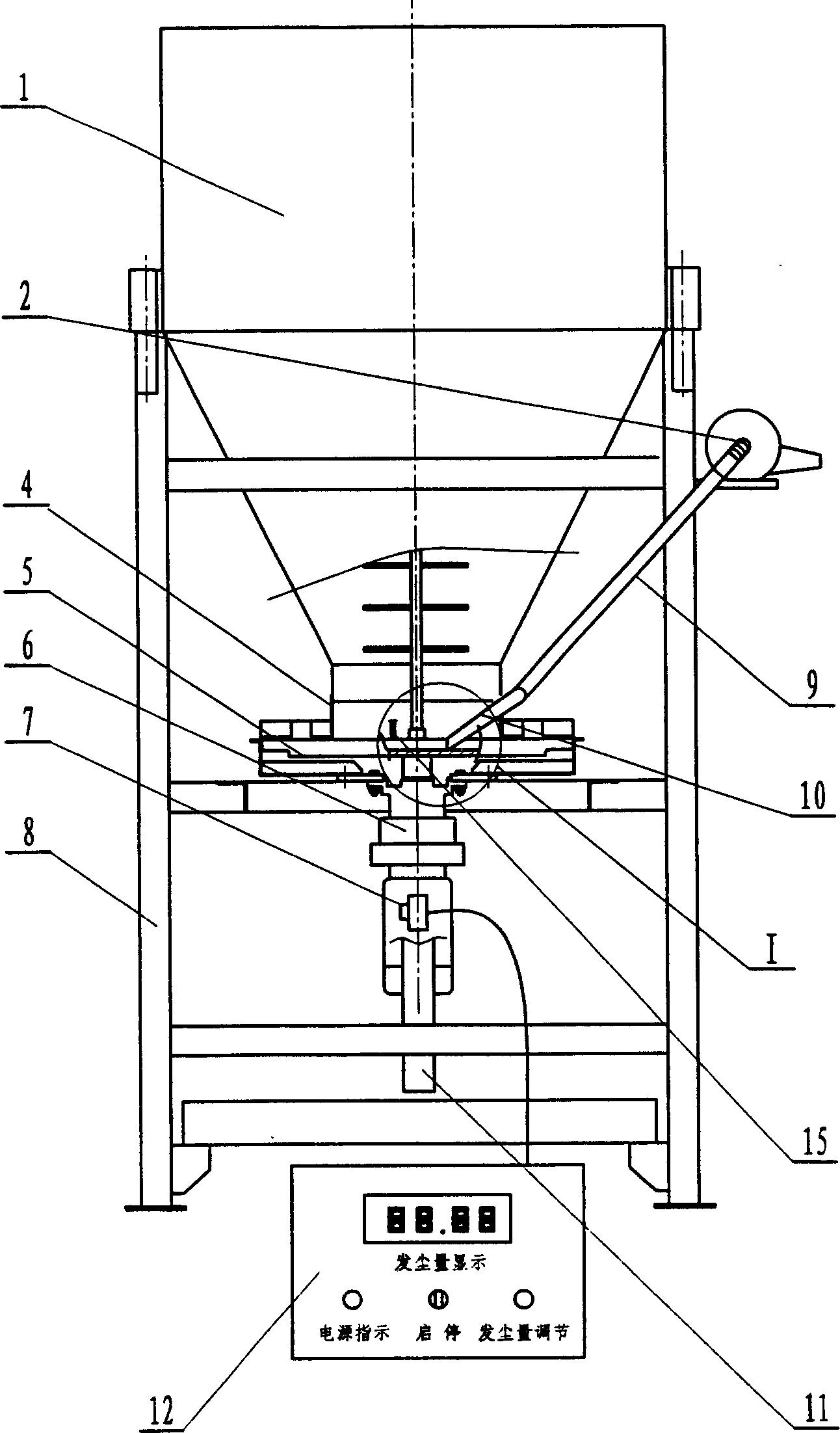

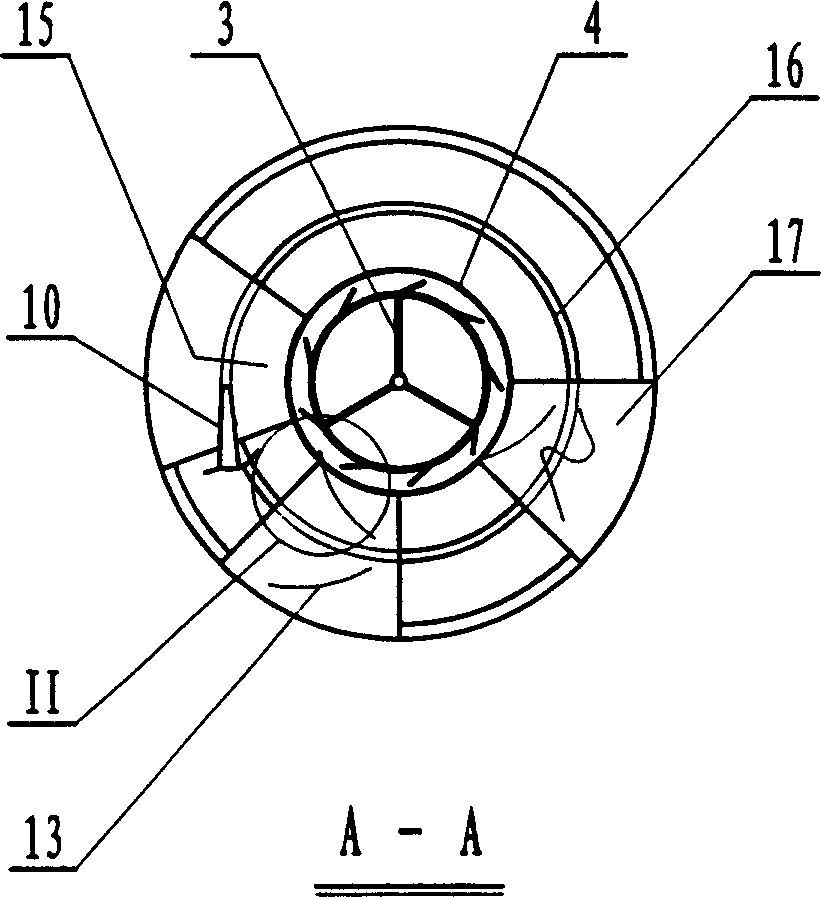

[0027] like figure 1 , figure 2 , The device is composed of ash storage hopper 1, feeding disc 5, motor 7, reducer 6 and powder suction and spraying. The motor 7 is controlled by the control box 12 with a frequency converter, so it is only necessary to open a circular groove 16 with a constant trapezoidal section on the feeding disk 5, the groove 16 is concentric with the disk 5, and the groove 16 is set scraper 15.

[0028] The ash storage hopper 1 is placed on the support frame 8 to load the powder material. Due to the large discharge opening, the problem of powder material blocking is alleviated.

[0029] In order to further solve the bridging and blocking problems of powder materials, a stirring conveyor 3 is installed in the ash storage hopper 1, such as Image 6 , Figure 7 As shown, the central part of the stirring conveyor 3 is a rotating shaft 18, the top of the rotating shaft 18 is provided with a stirring rod 19, the lower end of the rotating shaft 19 is a roun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com